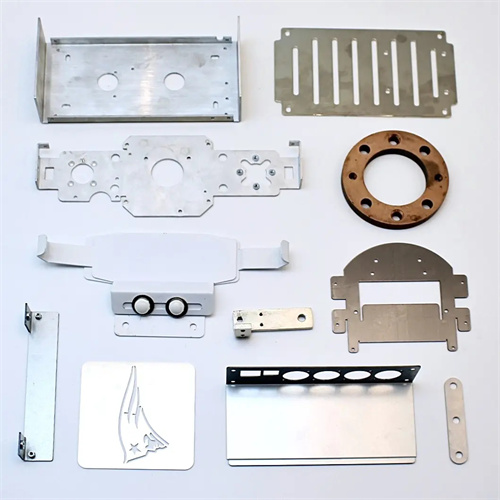

Application examples of metal surface conversion coating

The metal surface conversion film is a compound film that is generated on the metal surface by chemical or electrochemical methods and is firmly bonded to the substrate. Its main function is to improve the corrosion resistance of the metal, enhance the bonding strength with the coating, or give the surface specific physical properties. In the automotive industry, conversion film technology is most widely used, especially in the pre-treatment stage of car body painting. The phosphate film formed on the automobile body steel plate after phosphating treatment can significantly improve the adhesion of the electrophoretic primer and effectively prevent the car body from rusting during use. For example, the thickness of the phosphate film on a car body is usually controlled at 2-5 microns, and it is gray and crystalline. It can not only improve the salt spray resistance by 3-5 times, but also reduce the shedding rate of subsequent coatings by more than 90%, ensuring that the car body maintains its intact appearance for a long time in complex climatic environments.

In the aerospace sector, anodized aluminum alloys are a typical example of conversion coating applications. Aircraft fuselages and components are extensively made of aluminum alloy. The oxide film formed through anodizing can reach a thickness of 10-20 microns and a hardness of 300-500 HV, effectively protecting against erosion caused by high-altitude ultraviolet rays, sudden temperature fluctuations, and airflow. For example, the aluminum alloy wing leading edge of the Boeing 787, after undergoing a hard anodizing treatment, not only possesses excellent wear resistance but also reduces surface damage caused by airflow. Its insulating properties also prevent sparks from lightning strikes from interfering with internal equipment, ensuring flight safety.

In the electronics and electrical industry, the chromate passivation coating of zinc-nickel alloy plating is crucial for ensuring the reliability of electronic components. The metal casings and connectors of devices like smartphones and laptops often utilize zinc-nickel alloy plating combined with chromate passivation. This resulting passivation film, while only 0.1-0.5 microns thick, improves corrosion resistance by over 10 times. In humid environment testing, passivated connectors have demonstrated over 100,000 plug-in and pull-out cycles without corrosion, far exceeding the 10,000-cycle limit for untreated connectors. This ensures signal transmission stability during long-term use.

In the field of marine engineering, the application effect of phosphating-passivation composite conversion coating on steel components is remarkable. The steel piles and oil pipelines of offshore platforms are immersed in seawater or high humidity environments for a long time. The zinc phosphate film formed by phosphating treatment combined with the subsequent chromate passivation film can form a double protective barrier. For example, after the steel jacket of a deep-sea drilling platform was treated with this composite material, it could remain rust-free for more than 5,000 hours in a salt spray test, extending its lifespan by more than three times compared to traditional anti-corrosion treatments. This significantly reduces the corrosion rate of steel caused by chloride ions in the marine environment and reduces maintenance costs.

The daily necessities and hardware tool industries also rely on conversion coating technology. After passivation treatment, the oxide film formed on the surface of common stainless steel tableware effectively removes free iron, preventing the metallic odor caused by rust during use, while also improving its acid and alkali resistance. For example, phosphating the metal casing of power tools not only prevents rust in humid environments but also strengthens the bond with the powder coating, making the tool casing less susceptible to paint loss due to severe vibration and collision, thereby extending its service life. These application examples fully demonstrate the important role that conversion coatings on metal surfaces play in improving product performance and extending product life.