OUR CAPABILITIES

Custom Stamped Parts

Our customized stamping services are customer-oriented, providing a one-stop solution for stamped parts that require special shapes, unique sizes, or specific performance for your project. From non-ferrous metals such as brass and copper, to special steels such as spring steel and stainless steel, a variety of metal materials can be selected. Combined with customers' industry application scenarios, high-quality customized stamped parts that meet your needs can be created through innovative design and exquisite craftsmanship.

Brass Copper Stamped Parts

The brass and copper stamped parts we produce fully utilize the excellent conductivity and thermal conductivity of brass, as well as the excellent ductility of copper. We use advanced stamping technology to strictly control the design and forming process. Whether it is complex electronic connectors or exquisite decorative components, they can be precisely crafted to ensure smooth product surfaces and precise dimensions, meeting the diverse needs of different industries for brass and copper stamping parts.

Precision Stamped Parts

In the field of precision stamped parts, we rely on high-precision stamping equipment and advanced processing technology. For various metal materials, from mold design to stamping forming, every link undergoes strict testing and debugging to ensure that the produced precision stamping parts meet industry-leading standards in terms of dimensional accuracy, surface roughness, etc., and are widely used in fields such as electronics, medical, aerospace, etc. that require high precision.

Electrical Contacts

Electrical contacts are an important part of the switch. With the help of the conductivity of the electrical contacts, they play a high-quality switch between the operator and the product. The electrical contacts are mainly used in the film switching of hard board such as printed circuit board. Electrical contacts are crucial elements in electrical circuits. They are used in switches, relays, connectors, and other electrical components. Made from materials like silver, copper, or alloys, these contacts are designed to withstand high temperatures, resist wear, and minimize electrical resistance.

Battery Contacts

Battery Contacts / Electrical Contact Also known as battery connector contact, charger terminal, battery spring, battery buckle, etc. it's important component of electronic products, made of materials such as copper, iron, stainless steel, etc. Battery contacts are small, conductive components that connect the battery terminals to the device's circuitry. They come in various shapes and sizes, such as springs, clips, or flat contacts, and are usually made from metals like stainless steel or phosphor bronze. Their primary function is to maintain a stable electrical connection, ensuring consistent power supply to the device.

Terminal Connectors

Terminal connectors are electronic components used to connect wires and other devices. It is usually applied inside circuit boards or devices, mainly to transfer electrical energy from wire terminals to circuit boards or devices. Terminal connectors are devices used to join electrical conductors to a circuit or device. They come in various types, such as ring terminals, spade terminals, and butt connectors, and are often insulated to prevent short circuits. Made from conductive materials like copper or aluminum, terminal connectors ensure a secure and efficient electrical connection, making them essential in wiring and electrical systems.

Spring Steel Stamped Parts

The spring steel stamped parts we produce fully utilize the high-strength and high elasticity characteristics of spring steel. Through professional heat treatment processes and precise stamping technology, the products are endowed with stable and reliable elastic performance and mechanical strength. Whether it is a small spring plate or a large spring structural component, it can ensure good elasticity and shape stability under long-term use and frequent stress, meeting the strict requirements of the automotive, mechanical and other industries for spring steel stamping parts.

Stainless Steel Stamped Parts

Our stainless steel stamped parts rely on the advantages of stainless steel corrosion resistance, high strength, beauty and durability, and adopt advanced stamping processes and surface treatment technologies to ensure that the products can maintain excellent performance in various complex environments. From food processing equipment components to building decoration hardware, our stainless steel stamping parts not only have good functionality, but also meet the appearance and texture requirements, providing high-quality stainless steel stamping solutions for customers in different industries.

Stamped Metal Parts

We provide a wide range of metal stamped parts, covering a wide range of materials from common metals to special alloys. Relying on a mature stamping production system and rich manufacturing experience, we can efficiently produce both simple metal structural parts and complex shaped stamping parts, ensuring stable product quality and reliable performance. Through strict quality inspection processes, we ensure that every metal stamping part meets industry standards and customer requirements, providing solid component support for numerous industries.

Custom Stamped Parts Manufacturer

We are a strong professional stamped parts manufacturing enterprise with a modern production base of 8000 square meters, equipped with advanced automation equipment and standardized production lines, providing solid guarantees for the production of high-quality products. We are deeply engaged in the field of stamping parts, specializing in a full range of metal stamping products including brass copper stamped parts, customized stamping parts, precision stamped parts, spring steel stamping parts, stainless steel stamped parts, etc. From precision components for electronic communication to key structural components for mechanical equipment, it widely covers the application needs of multiple industries.

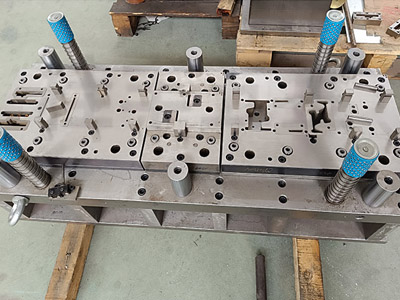

Custom Stamped Parts’ Molds

In terms of mold manufacturing, we are equipped with fast wire simple molds and slow wire high-precision molds. Fast wire simple molds, with their efficient processing speed and good cost-effectiveness, are suitable for manufacturing large quantities of stamped parts with moderate precision requirements and tight production cycles. They can quickly respond to customer needs and reduce production costs; The slow wire high-precision mold adopts advanced processing technology, which can achieve micrometer level processing accuracy, especially suitable for manufacturing high-precision molds required for precision stamped parts, ensuring the dimensional accuracy and surface quality of stamping parts from the source. We can provide reliable mold support for stamping production with our professional technical team and mature production experience, whether it is for routine production needs or high-precision, complex shaped mold customization.

Production Process Quality Management

With mature production processes, from strict screening of raw materials, mold design and manufacturing, to stamping and quality inspection, each link is controlled by a professional team to ensure product accuracy and stability. We attache great importance to product quality and environmental standards, and has successfully passed the ISO9001 quality management system and ISO14001 environmental management system certifications. At the same time, we provide comprehensive surface treatment services, covering various processes such as electroplating, spraying, passivation, etc., and are equipped with professional anti rust salt spray testing equipment. By simulating harsh environments to test the corrosion resistance of products, we ensure that the delivered stamped parts can maintain excellent performance in different scenarios. We are committed to providing high-quality and reliable stamping products and one-stop solutions for global customers.

Products Showcase

OUR SERVICES

Molding Service

As a professional mold service manufacturer, we can provide customers with comprehensive and high-quality mold solutions. Our mold services cover a variety of metal materials, including brass, copper, spring steel, stainless steel, etc. We can customize and produce various stamping molds according to customer needs. For conventional metal stamping molds, we rely on mature processes and strict quality control systems to ensure that the molds are stable and durable, and can efficiently complete large-scale production tasks; For precision stamping molds that require high precision, we use advanced processing technology and testing equipment to strive for excellence in every aspect from design, manufacturing to debugging, in order to achieve micrometer level processing accuracy and produce precision stamping parts that meet strict standards.

Professional Custom Stamped Parts Services

We specialize in providing customized services for various high-precision metal stamped parts, covering various materials such as brass, copper, stainless steel, spring steel, etc. We can produce various precision stamped parts, customized stamping parts, and metal stamping components. With advanced stamping technology and strict quality control system, we are able to provide customers with stamping solutions with precise dimensions and stable performance, meeting the personalized needs of different industries. From design to mass production, we provide one-stop metal stamping and forming services to ensure that products meet customer specifications and technical standards.

Surface Treatment Services

We provide comprehensive and professional stamping surface treatment services, which can be tailored to stamping parts made of various metal materials such as brass, copper, spring steel, stainless steel, as well as customized and precise stamping metal parts, to create suitable surface treatment solutions. Whether it is to improve corrosion resistance, enhance wear resistance, or improve the appearance texture, we can use advanced technology to customize your stamped parts from electroplating, spraying to passivation, polishing and other diversified treatment methods. Through strict quality control and precise process execution, every stamped metal product can demonstrate excellent quality while meeting functional requirements. With high-quality surface treatment services, we add value and competitiveness to your products.

OUR CERTIFICATES