Chromate passivation and chromate film

Chromate passivation and chromate film are two closely related concepts in metal surface treatment. Chromate passivation is the process of forming chromate film, and chromate film is the product of this process. The two together constitute an effective metal protection system. Chromate passivation is a process in which a metal workpiece is placed in a chromate solution and a protective film composed mainly of chromium compounds is formed on its surface by an oxidation-reduction reaction. This film is called a chromate film. It has a significant protective effect on metal substrates, and is especially widely used in the anti-corrosion treatment of metals such as zinc, aluminum, and steel. It is one of the classic surface protection technologies in the industrial field.

Chromate films have a complex chemical composition, primarily consisting of trivalent and hexavalent chromium oxides, hydroxides, and chromates. Trivalent chromium compounds form the bulk of the film, providing a physical barrier, while small amounts of hexavalent chromium are distributed within the pores and surface of the film, endowing it with self-healing properties. When the film is locally damaged, hexavalent chromium, along with water, penetrates the damaged area, reacting with the exposed metal surface to regenerate a passivation film, thereby preventing further corrosion. This unique self-healing property makes chromate films far more effective than conventional oxide or phosphate films.

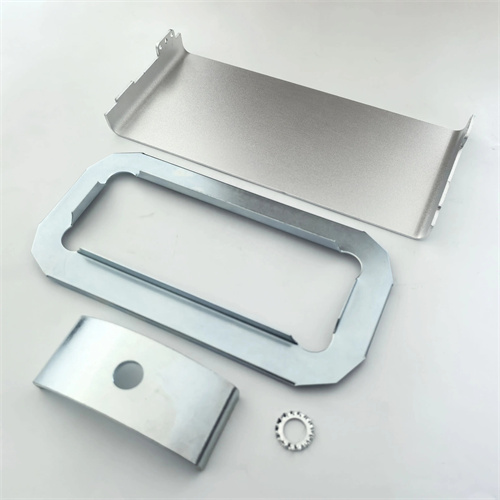

Structurally, chromate coatings typically exhibit a multilayered structure. The inner layer, tightly bonded to the metal substrate, is composed of dense trivalent chromium compounds, while the outer layer is relatively loose, containing a higher concentration of hexavalent chromium compounds and adsorbed water. The thickness of the coating varies depending on the treatment process and the type of metal, generally ranging from 0.1 to 2 microns. For example, the thickness of a colored chromate coating on galvanized steel is approximately 0.5 to 1.5 microns, while chromate coatings on aluminum and aluminum alloys are even thinner, typically 0.1 to 0.5 microns. This thin, dense structure ensures excellent protection without significantly affecting the dimensional accuracy and assembly performance of the metal workpiece.

During the chromate passivation process, control of process parameters directly impacts the quality of the chromate film. Factors such as the chromate concentration in the solution, pH, treatment temperature, and treatment time can alter the film’s composition, thickness, and structure. For example, increasing the chromate concentration increases the hexavalent chromium content in the film, enhancing its self-healing ability, but too high a concentration can lead to a roughened film. Excessive acidity (low pH) accelerates the dissolution of the metal matrix, weakening the film’s adhesion. Increasing the temperature accelerates the reaction and shortens the treatment time, but excessively high temperatures can cause the film to loosen and detach. Therefore, precise process parameters must be tailored to the specific metal material and protection requirements.

Despite the excellent protective properties of chromate films, their application is subject to increasingly stringent environmental regulations due to the high toxicity and carcinogenicity of hexavalent chromium. Currently, the industry is actively developing chromium-free passivation technologies, such as zirconium salt passivation and silane treatment, to replace traditional chromate passivation. However, these alternative technologies still lag behind chromate films in terms of self-healing capabilities and protective effectiveness. Therefore, chromate passivation and chromate films are still used in limited areas in certain fields with extremely high corrosion resistance requirements (such as aerospace and marine engineering). In the future, with the advancement of environmental protection technologies, it is expected that new passivation technologies that are both environmentally friendly and can maintain the excellent properties of chromate films will be developed.