Chromate passivation

Chromate passivation is a surface treatment technique that improves corrosion resistance by immersing metal workpieces in a chromate solution, where a chemical reaction forms a passive film primarily composed of chromate. This technique is particularly suitable for metals such as zinc, cadmium, aluminum, steel, and their alloys, and is most widely used in the post-treatment of galvanized steel. Chromate passivation films, primarily composed of trivalent and hexavalent chromium compounds, exhibit excellent chemical stability and self-healing properties. When the passive film is locally damaged, the surrounding chromate migrates to the damaged area, forming a new passive film that continues to provide protection.

The principle of chromate passivation treatment is based on the chemical properties of chromium. The hexavalent chromium in the chromate solution is highly oxidizing and can undergo a redox reaction with the metal surface. When a metal workpiece is immersed in the chromate solution, the metal surface is oxidized to form metal oxides, while the hexavalent chromium is reduced to trivalent chromium. The trivalent chromium combines with the metal oxides and chromates to form a continuous, dense passivation film on the metal surface. The formation of the passivation film involves dissolution of the metal surface, redox reactions, and film deposition. The entire process is influenced by factors such as solution concentration, temperature, pH, and treatment time.

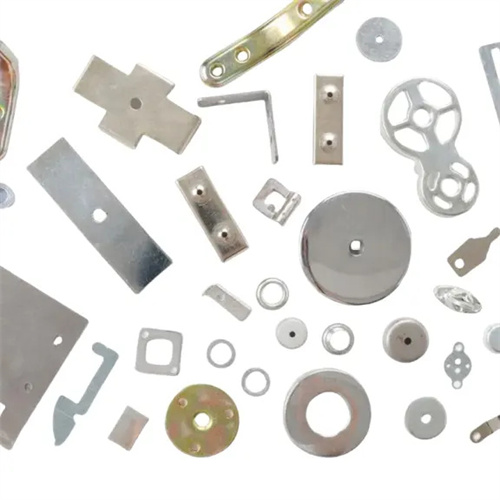

Chromate passivation treatment can be divided into color passivation, blue passivation, and black passivation according to the color of the passivation film. Color passivation films are thicker, usually 0.5-1.5μm, with rainbow colors and strong corrosion resistance, suitable for outdoor galvanized parts such as highway guardrails and power towers. Blue passivation films are thinner, about 0.1-0.3μm, with a light blue color and beautiful appearance, suitable for galvanized parts used for interior decoration. Black passivation films are moderately thick, black, and have good decorative properties and wear resistance, suitable for automotive parts, hardware tools, etc.

Chromate passivation treatment has the advantages of simple process, low cost and excellent passivation film performance. The operation process is relatively simple. You only need to immerse the pretreated workpiece in the chromate solution, take it out and wash it with water after a certain period of time. It does not require complicated equipment and operating skills. The passivation film is firmly bonded to the substrate and is not easy to fall off. It can significantly improve the corrosion resistance of the metal. For example, after chromate passivation treatment, the salt spray resistance of galvanized steel plates can be increased by 3-5 times. In addition, the passivation film also has good coating adhesion, which can provide a good foundation for subsequent coating processes.

However, chromate passivation also has significant drawbacks. Hexavalent chromium is a highly toxic and carcinogenic substance, posing a significant threat to human health and the environment. The wastewater and waste residue generated during the passivation process contain significant amounts of hexavalent chromium, which, if improperly handled, can cause severe environmental pollution. With growing environmental awareness and increasingly stringent environmental regulations, chromate passivation is gradually being replaced by chromium-free passivation methods, such as those using environmentally friendly passivating agents such as zirconium salts, titanium salts, and silanes. While these chromium-free passivation technologies may not match chromate passivation in terms of corrosion resistance, they can effectively reduce environmental pollution and represent the future direction of passivation technology development.