Equipment, process and influencing factors of electrophoretic coating

Electrophoretic coating equipment is the material basis for the electrophoretic coating process and is primarily composed of an electrophoretic tank, a circulating filtration system, a temperature control system, a rectifier power supply, an ultrafiltration system, and drying equipment. The electrophoretic tank is the core piece of equipment, welded from stainless steel. The tank dimensions are designed based on the workpiece size and production batch size, and a stirring device is installed inside to ensure uniformity of the tank liquid. The circulating filtration system pumps the tank liquid from the bottom of the tank through a pump, returning it to the tank after multiple layers of filtration (with an accuracy of up to 5-20μm), effectively removing impurities and particles from the tank liquid and preventing pinhole and shrinkage defects in the coating. The temperature control system utilizes both heating and cooling functions to stabilize the tank liquid temperature at 20-35°C, with temperature fluctuations controlled within ±1°C to ensure a stable electrophoretic process.

The rectifier power supply provides direct current, with an adjustable output voltage range of 0-300V. The appropriate voltage is selected based on the workpiece material and coating thickness. Typically, 80-200V is used for cathodic electrophoresis, and 50-150V for anodic electrophoresis. Ultrafiltration systems are unique to electrophoretic coating. They use ultrafiltration membranes to separate water and low-molecular impurities from the bath liquid and recycle the liquid removed by the workpiece, saving paint and reducing wastewater discharge. Drying equipment typically uses a hot air circulation oven, which precisely controls temperature and drying time to meet the curing requirements of different coatings.

The electrophoretic coating process consists of four stages: pretreatment, electrophoretic coating, post-cleaning, and drying. Pretreatment is crucial for ensuring coating quality and includes steps such as degreasing, rust removal, and phosphating. Degreasing uses an alkaline detergent to remove oil from the workpiece surface, with the temperature controlled at 50-60°C for 5-10 minutes. Rust removal involves pickling or sandblasting to remove rust and ensure a clean surface. Phosphating forms a uniform phosphate film on the workpiece surface, enhancing coating adhesion. The film thickness is controlled at 1-3μm. After pretreatment, the workpiece must be thoroughly rinsed to prevent residual chemicals from contaminating the bath solution.

During the electrophoretic coating stage, the workpiece acts as the cathode (or anode) and is suspended from a hanger and immersed in the electrophoretic bath. Once powered, the electric field causes paint particles to migrate to the workpiece surface and deposit, forming a coating. The electrophoretic coating time is typically 1-3 minutes, adjusted according to the desired coating thickness. The film thickness generally increases over time, but the rate of increase slows after a certain period. Post-cleaning removes any remaining undeposited bath liquid from the workpiece surface. Ultrafiltered water is used for step-by-step cleaning to minimize paint waste and wastewater pollution. During the drying stage, the workpiece is placed in an oven and baked at 160-180°C for 20-30 minutes to solidify the coating and form a hard protective film.

There are many factors that affect the quality of electrophoretic coating, mainly including bath parameters, process parameters and equipment status. The solid content of the bath liquid is controlled at 10%-20%. Too high will result in rough coating, while too low will affect the uniformity of film thickness. The pH value is usually maintained at 6.5-8.0. Deviating from the range will affect the stability and penetration of the coating. Voltage is a key factor affecting film thickness. Within a certain range, film thickness increases with increasing voltage, but excessively high voltage can easily produce pinholes and orange peel defects. Temperature has a significant effect on the viscosity of the bath solution and the deposition rate. Increasing the temperature will reduce the viscosity of the bath solution and accelerate the deposition rate, but exceeding 35°C may cause the stability of the bath solution to decrease.

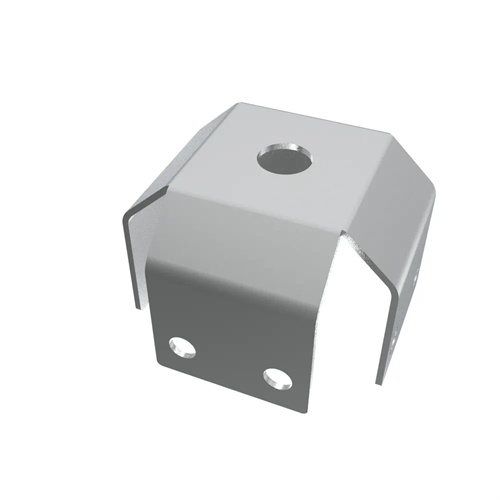

The design and mounting method of the workpiece hanger also affect coating uniformity. Complex workpieces require a rational arrangement of hanging points to ensure uniform electric field distribution and avoid thin coatings in shadowed areas. Furthermore, the bath’s circulation and stirring speed, filtration accuracy, and the operating status of the ultrafiltration system all directly impact coating quality. Regular equipment inspection and maintenance are necessary to ensure proper operation of all systems. In actual production, these factors require continuous monitoring and adjustment to consistently produce high-quality electrophoretic coatings.