Powder flame spraying

Powder flame spraying, a key branch of thermal spraying technology, utilizes a high-temperature flame generated by the combustion of a mixture of combustible gases (such as acetylene and propane) and oxygen to heat the spray powder to a molten or semi-molten state. Compressed air then atomizes the powder and sprays it at high speed onto the substrate, forming a coating. The technology’s core advantages lie in its simple equipment, flexible operation, and low cost. It is suitable for spraying powders of various metals, ceramics, and cermets. It can produce functional coatings with wear resistance, corrosion resistance, and heat insulation properties on substrates as diverse as metal, wood, and plastic. It is widely used in industries such as machinery manufacturing, petrochemicals, and the power industry.

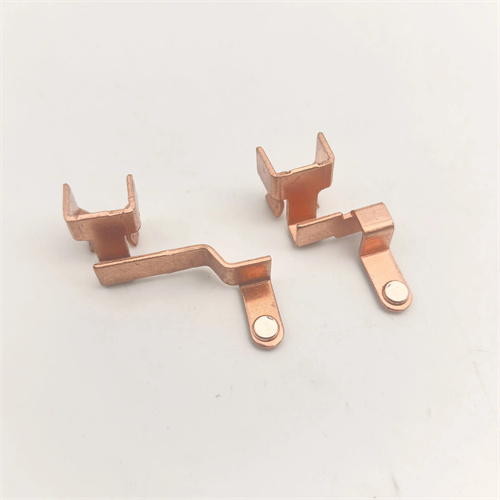

Powder flame spraying equipment primarily consists of a spray gun, oxygen and fuel gas supply systems, a powder delivery device, and a compressed air system. The spray gun is the core component, and its structural design determines the flame temperature and powder heating effect. Common spray guns include low-pressure and high-pressure spray guns. Low-pressure spray guns are suitable for general coatings, while high-pressure spray guns produce higher flame speeds and temperatures, suitable for high-melting-point materials. The oxygen and fuel gas supply systems require precise control of gas flow rates and ratios to maintain a stable flame temperature. Typically, a volume ratio of acetylene to oxygen of 1:1.2-1.5 produces a flame temperature of 2700-3200°C, sufficient to melt most spray powders.

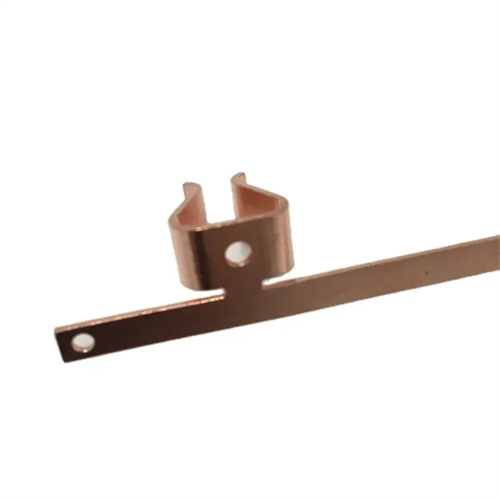

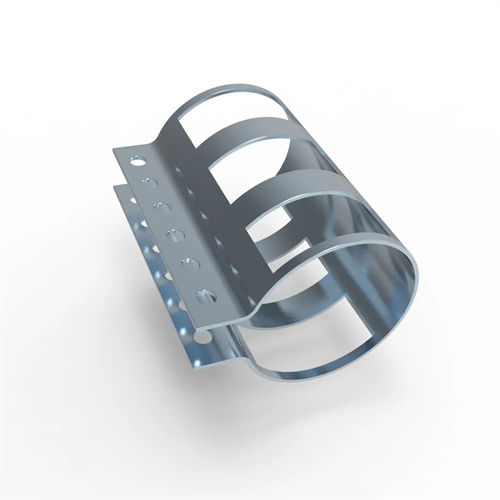

The powder feeder is responsible for evenly feeding the powder into the flame. Powder feeding methods include gravity feeding and pressure feeding. The powder feeding rate is generally 5-50g/min, which must match the flame energy to ensure sufficient melting of the powder. The compressed air system provides atomizing and accelerating gas at a pressure of 0.3-0.6MPa, accelerating the molten powder particles to 50-150m/s, causing them to impact the substrate surface at high speed.

The powder flame spraying process includes substrate pretreatment, spraying, and post-treatment. Pretreatment requires degreasing and roughening the substrate surface. Degreasing involves solvent cleaning or soaking in an alkaline solution to remove surface grease. Roughening involves sandblasting to a surface roughness of Ra 3.2-6.3μm, enhancing the mechanical bond between the coating and the substrate. During spraying, the distance between the spray gun and the substrate is controlled at 100-200mm, and the spray speed is 0.5-2m/min. The desired coating thickness is achieved through multiple spray passes, with a single spray pass thickness of 50-100μm and a total thickness generally ranging from 0.1-5mm.

Post-treatment is selected based on coating performance requirements. Wear-resistant coatings can be ground to improve surface finish; anti-corrosion coatings require pore sealing, using resin or metal slurry to fill pores. Powder flame spray coatings typically achieve a bond strength of 10-30 MPa and a porosity of 5%-15%. While lower than plasma spray coatings, these coatings are sufficient for general applications.

Limitations of this technology include relatively low flame temperatures, poor melting efficiency for high-melting-point ceramics, and low coating density. However, due to its simple equipment, low cost, and ease of operation, it remains widely adopted in small- and medium-scale production and on-site repairs. With the development of new powder materials and spray guns, coating performance continues to improve, and its application areas continue to expand.