Principles and characteristics of arc spraying

Arc spraying is a thermal spraying method that uses an electric arc to melt a metal wire at high temperatures. The molten metal is then atomized into droplets using a high-velocity airflow and sprayed onto the substrate to form a coating. The core principle is to generate an arc between two charged metal wires (which serve as consumable electrodes). The arc temperature can reach 3000-6000°C, high enough to melt most metals and alloys. As the wires are melted by the arc to form droplets, compressed air (or other gas) is ejected from a nozzle at high speed (typically 80-150 m/s), atomizing the droplets into fine particles (approximately 10-50 μm in diameter). These particles are then propelled to impact the pretreated substrate surface at high speed. The droplets undergo plastic deformation upon impact, bonding tightly to the substrate and rapidly cooling and solidifying. As the particles accumulate, a coating with a defined thickness and high performance is formed.

Arc spraying boasts high energy conversion efficiency, with electrical energy primarily converted directly into heat energy for molten metal via the arc. This minimizes heat loss, resulting in lower energy consumption and more cost-effective equipment operation compared to plasma spraying. Coating formation relies primarily on mechanical and micrometallurgical bonding, with bond strength typically ranging from 20-60 MPa. While lower than some plasma spray processes, this strength is sufficient for most wear-resistant and corrosion-resistant applications. Arc spraying offers a wide range of controllable coating thicknesses, typically 0.1-10 mm. Arc spraying can produce thin coatings for dimensional repairs or thicker coatings for wear protection, depending on the application.

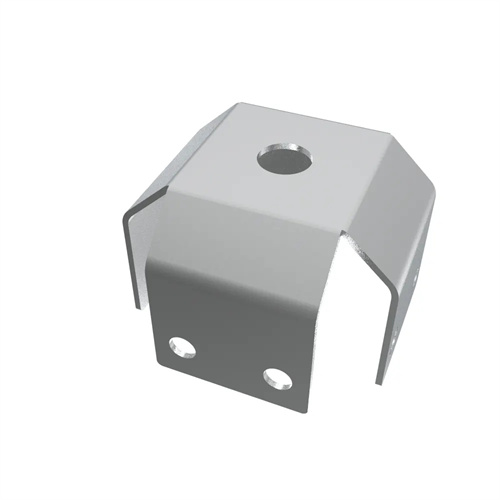

One of the notable features of arc spraying technology is its high production efficiency. Since wire is used as the spraying material, the feed rate is fast (usually 2-10kg/h), and the coating deposition rate can reach 0.5-5kg/h, far exceeding the powder thermal spray process. It is particularly suitable for large-area spraying of large components, such as bridge steel structures and anti-corrosion coatings on the outer walls of storage tanks. Secondly, the material utilization rate is high. The wire is almost completely melted in the arc, and most of the atomized particles are deposited on the surface of the substrate. The material utilization rate can reach more than 85%, reducing material waste. In addition, the structure of arc spraying equipment is relatively simple, mainly consisting of a power supply, a spray gun, a wire feeding mechanism, and a compressed air system. It is small in size and light in weight, making it easy to move on-site and especially suitable for field or on-site repair of large equipment.

Arc spraying is primarily suitable for metal and alloy wires, such as zinc, aluminum, copper, nickel-based alloys, iron-based alloys, and stainless steel. It can produce single metal coatings or alloy coatings (achieved by feeding different materials through a dual-wire process). For example, zinc-aluminum alloy coatings offer excellent sacrificial anodic protection and are widely used for corrosion protection of steel structures. Nickel-chromium alloy coatings, with their excellent high-temperature resistance, are suitable for protecting boiler pipes. However, arc spraying has limited suitability for high-melting-point ceramics, as the arc temperature is too high to melt the ceramics, limiting its application in high-temperature thermal insulation applications.

Arc spraying technology also has certain limitations. For example, the coating has a high porosity (typically 5%-15%), requiring sealing to improve corrosion resistance. Since it is sprayed in air, the coating is susceptible to oxidation, and for reactive metals (such as aluminum and magnesium alloys), oxide inclusions may form, affecting coating performance. The coating also has a high surface roughness (Ra 5-10μm), requiring subsequent machining for precise dimensional accuracy. Despite this, arc spraying, with its advantages of high efficiency, low cost, and ease of operation, still holds a significant position in the fields of corrosion protection, wear resistance, and repair . With technological advancements, coating quality is continuously improving through optimization of atomizing gas pressure and improvements to spray gun structure.