The Indispensable Role of Stamped Metal Parts in Industrial Applications

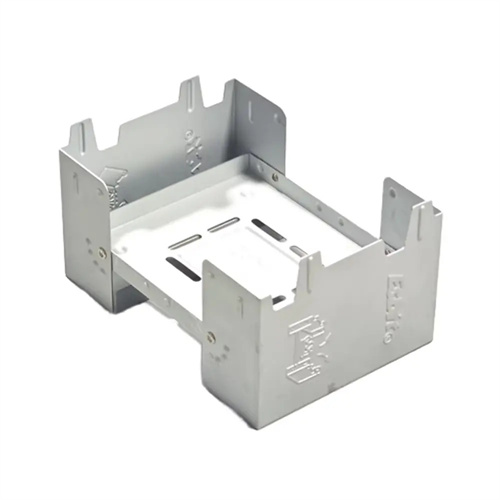

In the vast landscape of modern manufacturing, stamped metal parts, especially metal stamped bracket hardware and other metal components, have firmly established themselves as indispensable elements. Industries ranging from automotive and aerospace to electronics and construction rely on these parts to assemble functional and reliable products. A metal stamped bracket, for instance, can provide essential structural support, while other metal components may serve as connectors, fasteners, or protective casings.

The versatility of stamped metal parts lies in their ability to be customized to meet specific design requirements. Whether it’s a small, intricate component for a high – tech device or a large, robust bracket for heavy machinery, we can produce stamped metal parts that fit seamlessly into various applications. Their precision and durability make them a cornerstone of industrial manufacturing, enabling the creation of complex assemblies with ease and ensuring the long – term performance and safety of the final products.

Advantages of Metal Stamped Bracket Hardware and Other Stamped Metal Parts

Metal stamped bracket hardware and other stamped metal parts offer a multitude of advantages that make them the preferred choice for many manufacturers. One of the primary benefits is cost – effectiveness. Through the stamping process, we can produce parts in high volumes with relatively low production costs per unit. The use of automated stamping presses and precision dies reduces labor costs and increases production efficiency, allowing us to offer competitive pricing to our clients.

Another significant advantage is the high level of precision achievable. Our advanced stamping techniques and state – of – the – art equipment enable us to create parts with extremely tight tolerances. This precision ensures that each metal stamped bracket and component fits perfectly within its intended assembly, reducing the need for additional machining or adjustments. Additionally, stamped metal parts exhibit excellent mechanical properties, such as strength and durability, thanks to the work – hardening effect of the stamping process. This makes them capable of withstanding heavy loads, vibrations, and harsh environmental conditions, enhancing the overall reliability of the products they are used in.

Manufacturing Process of Stamped Metal Parts for Bracket Hardware and Metal Components

The manufacturing process of stamped metal parts for bracket hardware and other metal components is a well – orchestrated sequence of steps. It commences with the design phase, where our team of experienced engineers collaborates closely with clients to understand their requirements. Using advanced computer – aided design (CAD) software, we create detailed 3D models of the parts, optimizing the design for functionality, manufacturability, and cost – effectiveness.

Once the design is finalized, we source high – quality metal materials, such as steel, aluminum, or copper, based on the specific needs of the application. The metal sheets are then fed into our high – precision stamping presses, which are equipped with custom – made dies. The stamping process involves a series of operations, including punching, bending, and forming, to shape the metal into the desired bracket hardware or metal component. After stamping, additional processes like deburring, surface finishing, and heat treatment may be applied to enhance the part’s appearance, performance, and corrosion resistance. Throughout the process, strict quality control measures are in place to ensure that every stamped metal part meets our high – quality standards.

Applications of Stamped Metal Parts in Diverse Industries

Stamped metal parts, including metal stamped bracket hardware and various metal components, find extensive applications across diverse industries. In the automotive industry, they are used in engine compartments, chassis structures, and interior assemblies. Metal stamped brackets provide crucial support for engine components, while other metal components act as connectors for electrical systems and fasteners for body panels.

In the aerospace sector, precision – made stamped metal parts are essential for aircraft construction. They are used in wing structures, fuselage assemblies, and landing gear systems, where their high strength – to – weight ratio and reliability are of utmost importance. In the electronics industry, stamped metal parts serve as enclosures, heat sinks, and connectors, protecting sensitive components and ensuring proper functionality. Additionally, in the construction industry, metal stamped bracket hardware is used for building frames, bridges, and other structural applications, providing stability and strength.

Quality Control of Stamped Metal Parts for Bracket Hardware and Metal Components

Quality control is the cornerstone of our production of stamped metal parts for bracket hardware and other metal components. We implement a comprehensive quality management system that starts from the raw material inspection stage. Each batch of metal is rigorously tested for its chemical composition, mechanical properties, and surface quality to ensure it meets our stringent standards.

During the manufacturing process, our skilled technicians use advanced measuring tools, such as coordinate measuring machines (CMMs), optical comparators, and profilometers, to conduct in – line inspections. Statistical process control (SPC) techniques are also employed to monitor and analyze production data, allowing us to identify and correct any potential issues in real – time. After production, each part undergoes a final inspection, including functional testing, load – bearing tests, and corrosion resistance tests. By adhering to strict quality control measures, we guarantee that our stamped metal parts are reliable, durable, and of the highest quality.

Future Trends and Innovations in Stamped Metal Parts

As technology continues to evolve, the future of stamped metal parts, including metal stamped bracket hardware and metal components, is filled with exciting possibilities. We are constantly researching and developing new materials, such as advanced high – strength alloys and lightweight composites, to enhance the performance of our parts while reducing weight. The integration of artificial intelligence (AI) and machine learning (ML) into the stamping process is also on the horizon.

AI – powered systems can optimize die design, predict maintenance needs, and adjust stamping parameters in real – time, improving both the efficiency and quality of production. Additionally, the trend towards miniaturization and increased functionality in various industries will drive the demand for more complex and precise stamped metal parts. We are committed to staying at the forefront of these trends, investing in research and development, and adopting new technologies to provide our clients with the most advanced and reliable stamped metal parts for their future projects.