The Crucial Role of Stamped Metal Parts in EMI/RFI Protection

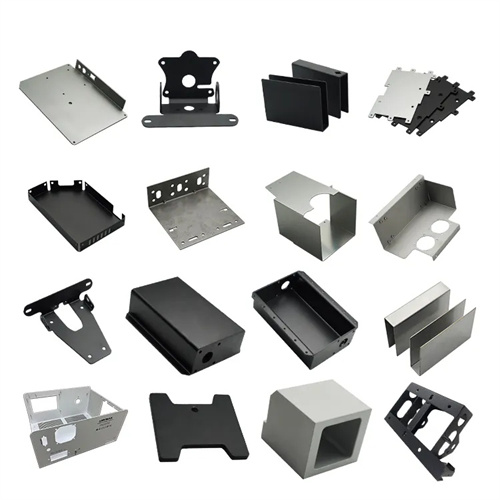

In today’s highly interconnected world, where electronic devices are omnipresent, electromagnetic interference (EMI) and radio – frequency interference (RFI) pose significant threats to the proper functioning of these devices. Stamped metal enclosures and shields have emerged as essential solutions for safeguarding electronics from unwanted electromagnetic signals. As manufacturers, we understand the criticality of providing reliable EMI/RFI protection, and stamped metal parts are at the forefront of our offerings.

Stamped metal enclosures and shields act as a barrier, preventing external EMI/RFI from infiltrating sensitive electronic components and also containing any electromagnetic emissions generated within the device. This dual – function protection is vital for maintaining the integrity, performance, and accuracy of electronic systems. Whether it’s in telecommunications, aerospace, or consumer electronics, the use of high – quality stamped metal parts for EMI/RFI protection ensures that devices operate smoothly without interference – related malfunctions.

How Stamped Metal Parts Provide EMI/RFI Protection

The effectiveness of stamped metal enclosures and shields in providing EMI/RFI protection lies in their physical and electrical properties. Stamped metal parts, typically made from conductive materials such as steel, aluminum, or copper, create a Faraday cage – like structure around the electronic components. When an electromagnetic wave encounters the metal enclosure or shield, the conductive material redirects and dissipates the energy, preventing it from reaching the internal components.

The seamless construction of stamped metal parts, achieved through precision manufacturing techniques, is crucial for maintaining the integrity of the shielding. Any gaps or discontinuities in the metal can compromise the EMI/RFI protection, allowing electromagnetic signals to leak in or out. At our facilities, we pay meticulous attention to the design and fabrication of stamped metal parts to ensure that they form a continuous and effective barrier against EMI/RFI, providing reliable protection for the enclosed electronics.

Manufacturing Process of Stamped Metal Enclosures and Shields

The manufacturing process of stamped metal enclosures and shields is a blend of advanced technology and skilled craftsmanship. We begin with the design phase, where our team of engineers uses state – of – the – art computer – aided design (CAD) software to create detailed 3D models of the parts. The design takes into account factors such as the size and shape of the electronic components to be enclosed, the required level of EMI/RFI protection, and the ease of manufacturing.

Once the design is finalized, we select the appropriate metal material based on its conductivity, strength, and cost – effectiveness. The metal sheets are then fed into our high – precision stamping presses, which are equipped with custom – made dies. The stamping process involves a series of operations, including punching, bending, and forming, to shape the metal into the desired enclosure or shield. After stamping, additional processes such as welding, riveting, and surface treatment may be carried out to enhance the structural integrity and EMI/RFI – shielding performance of the stamped metal parts.

Applications of Stamped Metal Parts for EMI/RFI Protection

Stamped metal enclosures and shields are widely used across a diverse range of industries to address EMI/RFI issues. In the aerospace industry, they are used to protect avionics systems from the harsh electromagnetic environment of flight. The reliability of EMI/RFI protection is crucial for ensuring the safety and proper operation of aircraft.

In the telecommunications sector, stamped metal parts are employed in base stations, routers, and other networking equipment. They prevent interference between different communication signals, ensuring clear and stable data transmission. In the consumer electronics industry, from smartphones and laptops to gaming consoles, stamped metal enclosures and shields safeguard the internal components from EMI/RFI, enhancing the user experience by preventing signal disruptions and improving device performance.

Quality Control of Stamped Metal Parts for EMI/RFI Protection

Quality control is of utmost importance in the production of stamped metal enclosures and shields for EMI/RFI protection. We start by rigorously inspecting the raw materials to ensure their conductivity, thickness, and overall quality meet our standards. During the manufacturing process, our skilled technicians use advanced measuring tools, such as coordinate measuring machines (CMMs) and optical comparators, to monitor the dimensions and shape of the stamped metal parts.

To verify the EMI/RFI – shielding effectiveness, we conduct specialized tests, including shielding effectiveness measurements using anechoic chambers. These tests simulate real – world electromagnetic environments and measure the ability of the stamped metal parts to block or attenuate electromagnetic signals. By implementing a comprehensive quality control system, we ensure that every stamped metal enclosure and shield we produce provides reliable and consistent EMI/RFI protection.

Future Trends in Stamped Metal Parts for EMI/RFI Protection

As technology continues to advance, the demand for more effective EMI/RFI protection solutions is on the rise, and stamped metal parts are evolving to meet these challenges. We are constantly researching and developing new materials and manufacturing techniques to enhance the shielding performance of stamped metal enclosures and shields. For example, the use of advanced conductive alloys and nanocomposites shows promise in providing even better EMI/RFI attenuation.

The integration of smart technologies, such as sensors and self – monitoring systems, into stamped metal parts is also an emerging trend. These technologies can detect changes in the electromagnetic environment and adjust the shielding performance accordingly. Additionally, with the increasing miniaturization of electronic devices, there is a growing need for thinner and more lightweight stamped metal enclosures and shields that can still provide robust EMI/RFI protection. We are committed to staying at the forefront of these trends and providing innovative solutions in stamped metal parts for EMI/RFI protection.