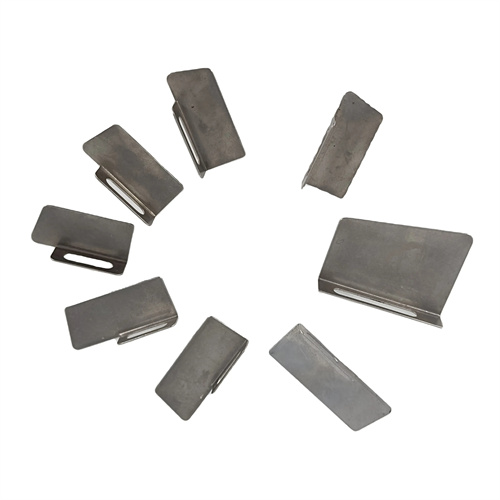

The Significance of Nickel Plated Spring Steel Stamped Metal Parts in Battery Connectors

In the rapidly evolving world of electronics and energy storage, custom stamped metal parts, especially those made from nickel plated spring steel for battery connectors, have become essential components. Battery connectors are the critical link that ensures a stable and reliable electrical connection between batteries and the devices they power. Any compromise in the quality or performance of these connectors can lead to power interruptions, reduced device lifespan, or even safety hazards.

Nickel plated spring steel offers a unique combination of properties that make it ideal for this application. Spring steel provides the necessary flexibility and resilience to maintain a secure connection, even under vibrations and mechanical stress. The nickel plating, on the other hand, enhances the corrosion resistance, electrical conductivity, and aesthetic appeal of the stamped metal parts. This combination allows our custom – made battery connectors to perform consistently in a wide range of environments, from the demanding conditions inside electric vehicles to the everyday use in consumer electronics.

Properties and Advantages of Nickel Plated Spring Steel for Stamped Metal Parts

Nickel plated spring steel brings several distinct advantages to the production of custom stamped metal parts for battery connectors. Spring steel is renowned for its high strength and excellent fatigue resistance. It can be repeatedly deformed and return to its original shape, which is crucial for battery connectors that may experience constant plugging and unplugging or movement due to device operation. This property ensures a long – lasting and reliable connection over time.

The nickel plating further enhances the performance of the spring steel. Nickel is highly resistant to corrosion, protecting the underlying spring steel from moisture, oxidation, and chemical damage. It also improves the electrical conductivity of the surface, reducing electrical resistance and minimizing power loss during transmission. Additionally, the smooth and shiny surface of nickel plating not only gives the stamped metal parts an attractive appearance but also makes them easier to clean and maintain. These combined properties make nickel plated spring steel a top – choice material for creating high – quality battery connectors.

Manufacturing Process of Custom Stamped Metal Parts for Nickel Plated Spring Steel Battery Connectors

Crafting custom stamped metal parts for nickel plated spring steel battery connectors requires a precise and well – orchestrated manufacturing process. We begin by sourcing high – quality spring steel sheets that meet our strict material standards. These sheets are then carefully inspected for their chemical composition, mechanical properties, and surface quality to ensure they are suitable for stamping.

Using advanced computer – aided design (CAD) software, our team creates detailed 3D models of the battery connectors, optimizing the design for functionality, manufacturability, and performance. The spring steel sheets are fed into our state – of – the – art stamping presses, which are equipped with custom – made dies. The dies perform a series of operations, including punching, bending, and forming, to shape the spring steel into the desired connector components with tight tolerances. After stamping, the parts undergo a meticulous nickel plating process, where a thin layer of nickel is applied to the surface through electroplating. This process not only enhances the performance but also provides a uniform and durable finish to the stamped metal parts.

Applications and Performance of Nickel Plated Spring Steel Stamped Metal Parts in Battery Connectors

Nickel plated spring steel stamped metal parts find extensive applications in various types of battery connectors. In the automotive industry, especially in electric and hybrid vehicles, these connectors are used to link the battery packs to the vehicle’s electrical systems. They must be able to withstand high currents, vibrations from the road, and temperature fluctuations. The flexibility of the spring steel ensures a secure connection, while the nickel plating protects against corrosion caused by moisture and road salts, ensuring the reliable operation of the vehicle’s power system.

For consumer electronics such as smartphones, laptops, and tablets, our custom battery connectors made from nickel plated spring steel offer a compact and efficient solution. They enable quick and easy battery installation and removal, while maintaining a stable electrical connection during device use. The high electrical conductivity of the nickel – plated surface reduces power loss, contributing to longer battery life and better device performance. Whether in large – scale industrial applications or small – scale consumer products, our nickel plated spring steel stamped metal parts in battery connectors deliver consistent and reliable performance.

Quality Control of Custom Stamped Metal Parts for Nickel Plated Spring Steel Battery Connectors

Quality control is the cornerstone of our production of custom stamped metal parts for nickel plated spring steel battery connectors. We implement a comprehensive quality management system that starts from the raw material stage. Every batch of spring steel is rigorously tested for its tensile strength, yield strength, and spring characteristics. The nickel plating process is also closely monitored to ensure the proper thickness, uniformity, and adhesion of the nickel layer.

During the manufacturing process, our skilled technicians use advanced measuring tools, such as coordinate measuring machines (CMMs) and optical comparators, to conduct in – line inspections. They check the dimensions, shape, and surface finish of the stamped metal parts to ensure they meet the specified tolerances. After production, each battery connector undergoes a series of final tests, including electrical conductivity testing, pull – out force testing, and corrosion resistance testing. By adhering to strict quality control measures and international standards, we guarantee that our custom stamped metal parts for nickel plated spring steel battery connectors are of the highest quality and reliability.

Future Trends and Innovations in Nickel Plated Spring Steel Stamped Metal Parts for Battery Connectors

As technology continues to advance, the future of nickel plated spring steel stamped metal parts for battery connectors is filled with exciting possibilities. We are actively researching and developing new manufacturing techniques to further improve the precision and efficiency of production. For example, the integration of automation and robotics in the stamping and plating processes can increase productivity while maintaining high – quality standards.

There is also a growing focus on developing more sustainable manufacturing methods. We aim to reduce waste, minimize energy consumption, and explore eco – friendly alternatives for the nickel plating process. Additionally, as battery technologies evolve towards higher voltages and greater energy densities, we are working on enhancing the performance of our battery connectors. This includes researching new alloys for spring steel and improving the nickel plating process to better meet the demands of future – generation batteries, ensuring that our custom stamped metal parts remain at the forefront of innovation in the industry.