The Indispensable Role of Stainless Steel Stamped Parts in Electronics Instruments

In the realm of electronics instruments, stainless steel stamped parts have become an indispensable component, playing a crucial role in ensuring the functionality, durability, and precision of these devices. As electronics instruments continue to evolve towards smaller, more complex, and high-performance designs, the demand for components that can withstand various environmental factors and mechanical stresses has grown significantly. Stainless steel, with its excellent mechanical properties, corrosion resistance, and aesthetic appeal, offers the perfect solution.

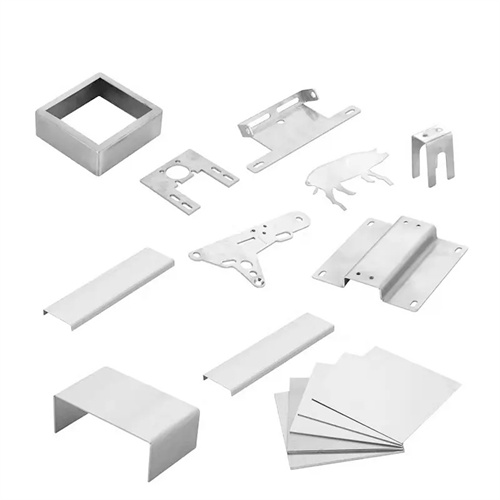

Stamped parts made from stainless steel provide the necessary structural support for delicate electronic components. They can endure the rigors of daily use, vibrations, and temperature fluctuations without deforming or losing their integrity. Moreover, the non-magnetic and electrically conductive properties of certain stainless steel grades make them suitable for applications where electromagnetic interference needs to be minimized. From simple connectors to complex enclosures, stainless steel stamped parts are the backbone of modern electronics instruments, enabling reliable and efficient operation.

Advantages of Stainless Steel Stamped Parts for Electronics Instrument Fabrication

When it comes to fabricating components for electronics instruments, stainless steel stamped parts offer a plethora of advantages. First and foremost is their corrosion resistance. In environments where moisture, humidity, or exposure to chemicals is common, stainless steel stamped parts maintain their performance over time. This is particularly important for electronics instruments used in industrial settings, laboratories, or outdoor applications, where corrosion can quickly render a device inoperable.

The precision achievable in the stamping process is another significant benefit. We can create stainless steel stamped parts with extremely tight tolerances, ensuring a perfect fit for the intricate assemblies within electronics instruments. This precision not only simplifies the assembly process but also enhances the overall reliability of the instrument. Additionally, stainless steel is highly formable, allowing us to produce parts with complex geometries that meet the specific design requirements of electronics instruments. Its ability to be easily machined, welded, and finished further adds to its versatility in fabrication.

Fabrication Process of Stainless Steel Stamped Parts for Electronics Instruments

The fabrication of stainless steel stamped parts for electronics instruments is a meticulous process that combines advanced technology and skilled craftsmanship. We begin by carefully selecting the appropriate grade of stainless steel, taking into account factors such as the instrument’s operating environment, mechanical requirements, and cost. Once the material is sourced, our design team uses state-of-the-art computer-aided design (CAD) software to create detailed blueprints of the parts.

These designs are then translated into reality using high-precision stamping presses and custom-made dies. The stamping process involves feeding a sheet of stainless steel into the press, where the die shapes the metal according to the design. Depending on the complexity of the part, multiple stamping operations may be required, including punching, bending, and forming. After stamping, the parts undergo post-processing steps such as deburring, polishing, and surface treatment to enhance their appearance and performance. Quality control checks are carried out at every stage to ensure that the stainless steel stamped parts meet our stringent standards.

Applications of Stainless Steel Stamped Parts in Electronics Instrument Components

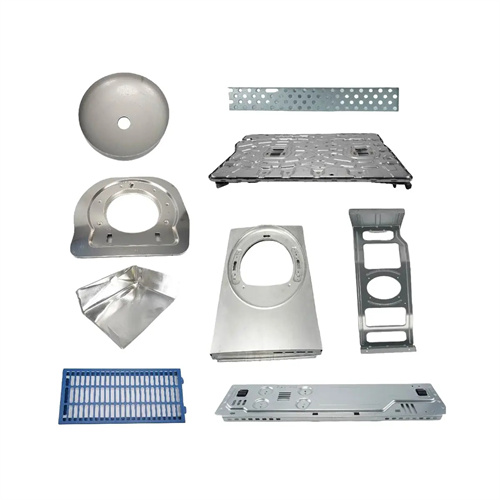

Stainless steel stamped parts find diverse applications within the various components of electronics instruments. In instrument enclosures, these parts provide the structural framework and protection for internal components. They shield sensitive electronics from dust, moisture, and physical damage, while also offering electromagnetic shielding to prevent interference. The sleek and durable finish of stainless steel enclosures also gives the instruments an aesthetically pleasing appearance.

For connectors and terminals, stainless steel stamped parts ensure reliable electrical connections. Their high conductivity and resistance to oxidation maintain stable signal transmission, even in harsh conditions. In addition, stainless steel is used in the fabrication of heat sinks, which play a crucial role in dissipating heat generated by electronic components. The excellent thermal conductivity of stainless steel, combined with the precision of the stamping process, allows for the creation of efficient heat sink designs that keep the instrument’s temperature within optimal levels, ensuring its longevity and performance.

Quality Control of Stainless Steel Stamped Parts for Electronics Instruments

Quality control is of utmost importance in the fabrication of stainless steel stamped parts for electronics instruments. We implement a comprehensive quality management system that starts with the inspection of raw materials. Each batch of stainless steel is rigorously tested for its chemical composition, mechanical properties, and surface finish to ensure compliance with industry standards.

During the manufacturing process, in-line inspections are conducted using advanced measuring tools such as coordinate measuring machines (CMMs), optical comparators, and profilometers. These tools allow us to monitor the dimensions, shape, and surface roughness of the parts in real-time, ensuring that they meet the specified tolerances. After production, final inspections include functional testing, salt spray testing for corrosion resistance, and stress testing to verify the parts’ performance under various conditions. By adhering to strict quality control measures, we guarantee that our stainless steel stamped parts are reliable, durable, and suitable for use in high-precision electronics instruments.

Future Trends in Stainless Steel Stamped Parts for Electronics Instrument Fabrication

As the electronics industry continues to advance at a rapid pace, the future of stainless steel stamped parts for electronics instrument fabrication is filled with exciting possibilities. We are constantly researching and developing new technologies and techniques to improve the performance and efficiency of our products. For instance, the integration of artificial intelligence (AI) and machine learning into the design and manufacturing processes will enable us to optimize part designs, predict potential manufacturing issues, and enhance production efficiency.

There is also a growing trend towards miniaturization and increased functionality in electronics instruments, which will drive the demand for even more precise and complex stainless steel stamped parts. We are exploring new materials and processing methods to meet these challenges, such as using advanced alloys with enhanced properties and adopting micro-stamping techniques for ultra-precision manufacturing. Additionally, with the increasing focus on sustainability, we aim to develop more environmentally friendly fabrication processes for stainless steel stamped parts, reducing waste and energy consumption while maintaining high-quality standards.