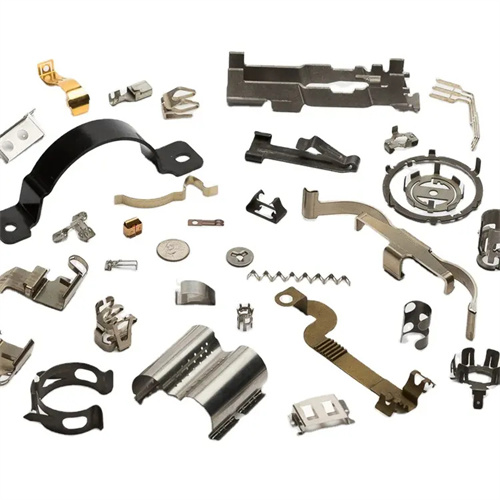

The Imperative of High-Corrosion-Resistance in Stainless Steel Stamped Parts

In industries where operations take place in harsh environments, the demand for components that can withstand extreme conditions is non-negotiable. High-corrosion-resistant stainless steel stamped parts have emerged as the go-to solution, and for good reason. Harsh environments, whether characterized by high humidity, exposure to saltwater, abrasive chemicals, or fluctuating temperatures, pose a significant threat to the integrity of traditional metal components. Rust, degradation, and structural failure are common consequences, leading to costly downtime and safety risks.

Stainless steel, with its unique alloy composition, offers superior protection against corrosion. The chromium content in stainless steel forms a passive oxide layer on the surface, acting as a shield that prevents oxygen and moisture from penetrating the metal. This inherent property makes high-corrosion-resistant stainless steel stamped parts ideal for applications where durability and reliability are crucial. From offshore oil rigs to chemical processing plants, these parts ensure that equipment continues to function optimally, even in the most challenging conditions.

Crafting High-Corrosion-Resistant Stainless Steel Stamped Parts

Our process of creating high-corrosion-resistant stainless steel stamped parts is a blend of advanced technology and expert craftsmanship. It begins with the selection of the right grade of stainless steel. Grades such as 316 and 317, known for their enhanced resistance to chloride-induced corrosion, are often preferred for applications in marine and chemical environments. Once the material is chosen, we utilize state-of-the-art computer-aided design (CAD) and computer numerical control (CNC) stamping machines.

The CAD software allows us to create precise designs tailored to the specific requirements of our clients, while the CNC machines ensure accurate and consistent stamping of the parts. During the stamping process, we pay close attention to maintaining the integrity of the material’s surface. Any damage to the surface could compromise the passive oxide layer and reduce the part’s corrosion resistance. After stamping, additional processes such as heat treatment and surface finishing may be applied to further enhance the corrosion resistance and mechanical properties of the stainless steel stamped parts.

Stainless Steel Stamped Parts in Marine and Offshore Harsh Environments

In marine and offshore environments, where saltwater, high humidity, and strong winds are the norm, high-corrosion-resistant stainless steel stamped parts play a vital role. In offshore oil and gas platforms, these parts are used in structural components, such as frames and support brackets, ensuring the stability and safety of the entire installation. The constant exposure to saltwater spray and moisture can quickly corrode conventional metals, but our stainless steel stamped parts remain intact, providing long-lasting performance.

For ships and boats, stainless steel stamped parts are utilized in various applications, from hull fittings to deck hardware. The corrosion resistance of these parts not only extends their lifespan but also reduces the need for frequent maintenance. In addition, in underwater equipment such as subsea valves and connectors, high-corrosion-resistant stainless steel stamped parts are essential for preventing leaks and ensuring reliable operation in the harsh marine environment.

Withstanding Chemical and Industrial Harsh Environments with Stainless Steel Stamped Parts

Chemical processing plants and other industrial facilities present their own set of challenges in terms of corrosion. Aggressive chemicals, high temperatures, and abrasive substances can quickly degrade the quality of components. High-corrosion-resistant stainless steel stamped parts are specifically engineered to withstand these harsh conditions. In chemical reactors and pipelines, these parts are used to transport and process corrosive fluids without the risk of leaks or material failure.

The resistance of stainless steel to a wide range of chemicals, including acids, alkalis, and solvents, makes it an ideal choice for such applications. In addition, in power plants, where components are exposed to high temperatures and steam, our stainless steel stamped parts maintain their strength and integrity. Whether it’s in the manufacturing of pharmaceuticals, petrochemicals, or other industrial products, high-corrosion-resistant stainless steel stamped parts ensure the smooth and safe operation of equipment in the face of harsh chemical and industrial environments.

Quality Assurance for High-Corrosion-Resistant Stainless Steel Stamped Parts

Quality assurance is at the forefront of our production of high-corrosion-resistant stainless steel stamped parts. We start by sourcing materials from reputable suppliers who adhere to strict international standards. Each batch of stainless steel is thoroughly tested for its chemical composition, mechanical properties, and corrosion resistance before it enters the production process.

During manufacturing, our skilled technicians closely monitor every step of the stamping process to ensure that the parts meet our exacting specifications. Advanced inspection tools, such as ultrasonic testing and optical microscopy, are used to detect any internal flaws or surface imperfections. After production, the parts undergo rigorous corrosion testing, including salt spray tests and exposure to simulated harsh environments. Only parts that pass these comprehensive quality checks are approved for delivery, guaranteeing that our clients receive high-corrosion-resistant stainless steel stamped parts that are reliable and durable.

Future Innovations in High-Corrosion-Resistant Stainless Steel Stamped Parts

As industries continue to evolve and face new challenges in harsh environments, we are committed to driving innovation in the production of high-corrosion-resistant stainless steel stamped parts. Research is underway to develop new alloys and manufacturing techniques that offer even higher levels of corrosion resistance. For example, the integration of nanotechnology into stainless steel production shows promise in creating ultra-thin, yet highly effective, protective layers.

We are also exploring ways to make our manufacturing processes more sustainable without sacrificing quality. This includes reducing energy consumption, minimizing waste, and using environmentally friendly materials. Additionally, the development of smart monitoring systems for our stainless steel stamped parts will allow for real-time assessment of their corrosion status in the field, enabling proactive maintenance and 延长 component lifespan. By staying at the forefront of technological advancements, we aim to provide our clients with the most advanced and reliable high-corrosion-resistant stainless steel stamped parts for harsh environments in the future.