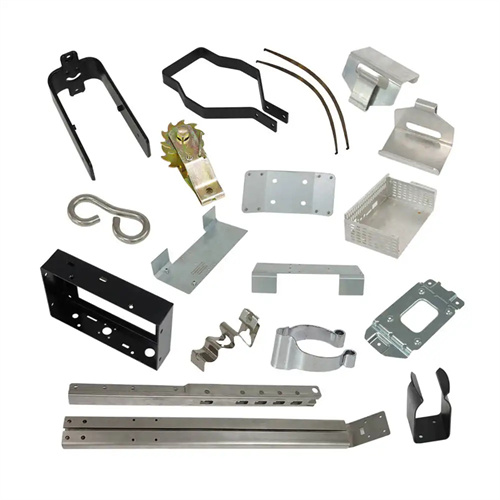

Introduction to Spring Steel Stamped Parts in Retaining Clips & Fasteners

As a team with a deep understanding of metal fabrication and engineering solutions, we recognize the indispensable role that Spring Steel Stamped Parts play in retaining clips and fasteners. In countless applications across diverse industries, from automotive and aerospace to electronics and machinery, the reliability and functionality of these components are crucial for the proper assembly and operation of various systems. Spring steel, with its remarkable combination of elasticity, strength, and fatigue resistance, provides the perfect foundation for crafting retaining clips and fasteners that can withstand demanding conditions.

Our expertise in custom – engineering Spring Steel Stamped Parts for retaining clips and fasteners allows us to offer tailored solutions that meet the unique requirements of our clients. Whether it’s a specific size, shape, or performance specification, we take pride in our ability to design and manufacture components that not only secure parts effectively but also contribute to the overall durability and efficiency of the final product.

The Outstanding Advantages of Custom – Engineered Spring Steel Stamped Parts

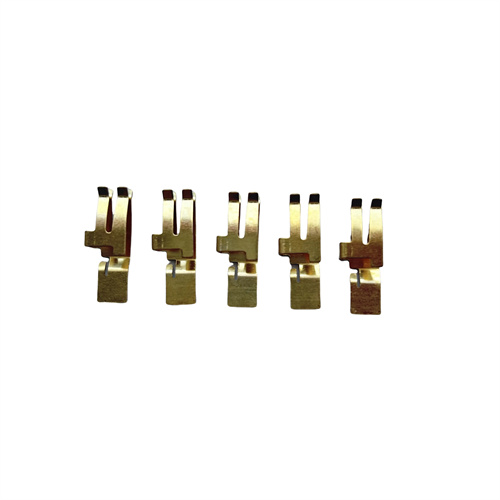

We are well – aware of the outstanding advantages that our custom – engineered Spring Steel Stamped Parts bring to retaining clips and fasteners. The elasticity of spring steel enables our clips to maintain a consistent clamping force, ensuring a secure hold even under vibrations, temperature fluctuations, or mechanical stress. This is particularly vital in applications where loose connections could lead to system failures or safety hazards.

The high strength and fatigue resistance of spring steel make our fasteners capable of enduring repeated loading and unloading cycles without deforming or breaking. In industries where components are frequently assembled and disassembled, such as in maintenance and repair operations, the longevity of our Spring Steel Stamped Parts significantly reduces replacement costs and downtime. Additionally, the custom – engineering aspect allows us to optimize the design of these parts, integrating features like corrosion – resistant coatings or specific geometries to enhance performance in different environments. These combined advantages make our custom – engineered Spring Steel Stamped Parts a reliable and cost – effective choice for a wide range of applications.

The Detailed Custom Engineering Process of Spring Steel Stamped Parts

Our custom engineering process for Spring Steel Stamped Parts used in retaining clips and fasteners is a meticulous and collaborative journey. It commences with in – depth consultations with our clients to fully understand their project needs, including the intended application, environmental conditions, and any specific performance criteria. Our team of experienced engineers and designers then utilizes advanced CAD/CAM software to create detailed 3D models of the parts, exploring various design options to achieve the optimal balance between functionality, manufacturability, and cost.

Once the initial designs are proposed, we engage in further discussions with the client to incorporate feedback and make any necessary adjustments. After finalizing the design, we source high – quality spring steel materials from trusted suppliers. The materials are then processed through our state – of – the – art stamping equipment, where custom – made dies are used to shape the steel into the desired form. Throughout the stamping process, we closely monitor and control parameters such as pressure, speed, and temperature to ensure consistent quality and dimensional accuracy. Post – stamping, the parts may undergo additional processes like heat treatment, surface finishing, and precision machining to meet the exacting requirements of the custom design. Rigorous quality inspections are carried out at every stage to guarantee that each Spring Steel Stamped Part meets our stringent standards.

Applications of Spring Steel Stamped Parts in the Automotive Industry

In the automotive industry, our Spring Steel Stamped Parts in retaining clips and fasteners are widely utilized and play a critical role. In engine compartments, our clips secure hoses, wires, and fuel lines, preventing them from coming loose due to vibrations generated by the engine. The consistent clamping force provided by our spring steel clips ensures reliable connections, reducing the risk of fluid leaks or electrical failures.

For body assembly, our fasteners are used to join various components, such as panels and frames. The high strength and durability of our Spring Steel Stamped fasteners enable them to withstand the stresses of daily driving, as well as the rigors of collisions and impacts. In suspension systems, our retaining clips hold components like shock absorbers and springs in place, contributing to the vehicle’s stability and handling. By providing custom – engineered solutions, we help automotive manufacturers enhance the safety, performance, and reliability of their vehicles.

Applications of Spring Steel Stamped Parts in Electronics and Aerospace Sectors

In the electronics industry, our Spring Steel Stamped Parts are essential for ensuring the secure assembly of delicate components. In smartphones, laptops, and other portable devices, our retaining clips hold circuit boards, batteries, and connectors in position, protecting them from damage caused by movement or shocks. The precision of our custom – engineered parts allows for a snug fit, preventing interference with other components and ensuring proper functionality.

For the aerospace sector, where safety and reliability are non – negotiable, our Spring Steel Stamped fasteners and retaining clips are used in critical applications. In aircraft engines and structural assemblies, these components must withstand extreme temperatures, high pressures, and significant mechanical loads. Our custom – engineered solutions are designed to meet the stringent requirements of the aerospace industry, providing secure connections that can be relied on during flight. Whether it’s in small electronic devices or large – scale aerospace systems, our Spring Steel Stamped Parts contribute to the integrity and performance of the final products.

Future Prospects of Spring Steel Stamped Parts in Custom Engineered Retaining Clips & Fasteners

Looking to the future, we are highly optimistic about the prospects of our Spring Steel Stamped Parts in custom engineered retaining clips and fasteners. As industries continue to evolve and embrace new technologies, the demand for specialized, high – performance components will only increase. The growth of electric vehicles, the development of advanced electronics, and the expansion of space exploration initiatives will all drive the need for custom – engineered solutions that can meet ever – more complex requirements.

We are committed to continuous research and development to stay at the forefront of this evolving market. Our team will explore new spring steel alloys with enhanced properties, develop innovative stamping techniques for more intricate designs, and leverage advanced simulation and modeling tools to optimize the custom engineering process. By maintaining our focus on quality, innovation, and customer satisfaction, we aim to meet the changing needs of our clients across various industries and remain a leading provider of Spring Steel Stamped Parts for custom engineered retaining clips and fasteners.