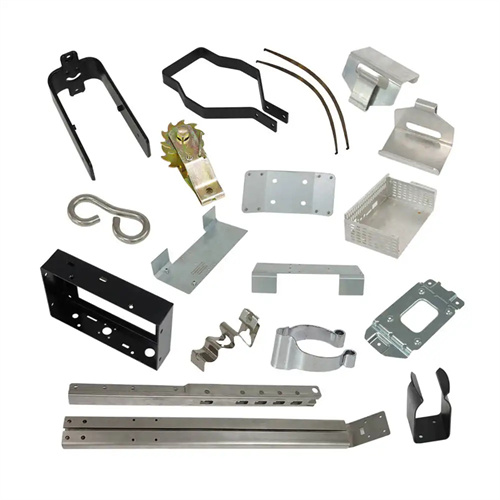

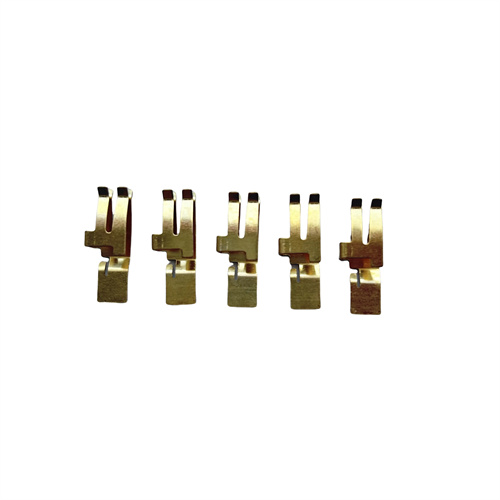

Introduction to Custom Nickel Plated Spring Steel Stamped Parts

As a team with extensive experience in metal stamping, we understand the unique value that Custom Nickel Plated Spring Steel Stamped Parts bring to various industries. Spring steel, known for its excellent elasticity and strength, serves as the perfect base material for creating reliable components. When combined with nickel plating and bending stamping techniques to produce metal clips, these parts offer a remarkable blend of functionality, durability, and corrosion resistance.

In today’s competitive market, where precision and customization are highly valued, our custom – made parts cater to the specific needs of our clients. Whether it’s for electronics, automotive, or household applications, the demand for high – quality metal clips made from nickel – plated spring steel is on the rise. We take pride in our ability to leverage advanced manufacturing processes to produce Spring Steel Stamped Parts that not only meet but exceed industry standards, providing solutions that enhance the performance and lifespan of the final products.

The Unique Advantages of Custom Nickel Plated Spring Steel Stamped Parts

We are well – aware of the unique advantages that our Custom Nickel Plated Spring Steel Stamped Parts possess. The nickel plating offers exceptional corrosion resistance, protecting the spring steel from oxidation and environmental factors. This is particularly crucial in applications where the parts are exposed to moisture, chemicals, or high humidity. The plating also provides a smooth, attractive surface finish, enhancing the aesthetic appeal of the metal clips.

The inherent properties of spring steel, such as its high elasticity and fatigue resistance, ensure that our stamped parts can withstand repeated bending and stress without losing their shape or performance. This makes them ideal for metal clips that need to securely hold or connect components, as they can maintain a consistent clamping force over time. Additionally, the precision of our bending stamping process allows for the creation of complex shapes and tight tolerances, ensuring a perfect fit for various applications. The combination of these features makes our Custom Nickel Plated Spring Steel Stamped Parts a reliable and versatile choice for a wide range of industries.

The Comprehensive Fabrication Process of Spring Steel Stamped Parts

Our fabrication process for Spring Steel Stamped Parts is a comprehensive and meticulously planned sequence of steps. It begins with in – depth consultations with our clients to fully understand their specific requirements, including the intended use, design specifications, and performance expectations of the metal clips. Our team of experienced engineers then uses advanced CAD/CAM software to create detailed 3D models of the parts, optimizing the design for functionality, manufacturability, and cost – effectiveness.

Once the designs are finalized, we source high – quality spring steel materials from trusted suppliers. These materials are then fed into our state – of – the – art stamping presses, which are equipped with custom – made dies for bending and stamping operations. During the process, we closely monitor and control parameters such as pressure, speed, and temperature to ensure consistent quality and dimensional accuracy. After stamping and bending, the parts undergo nickel plating. This involves cleaning the surface, applying a nickel layer through electroplating, and then finishing with processes like polishing or passivation to enhance the plating’s durability. Rigorous quality inspections are carried out at every stage to guarantee that each Spring Steel Stamped Part meets our strict quality standards before being delivered.

Applications of Spring Steel Stamped Parts in the Electronics Industry

In the electronics industry, our Custom Nickel Plated Spring Steel Stamped Parts, especially metal clips, play a vital role. These clips are used to secure components on circuit boards, hold cables in place, and provide electrical connections. The corrosion resistance of the nickel plating is essential in protecting the clips from the effects of soldering fluxes and other chemicals used in the manufacturing process, ensuring long – term reliability.

For example, in smartphones and laptops, our metal clips are used to hold battery connectors, ensuring a stable electrical connection. The high elasticity of the spring steel allows the clips to maintain a firm grip even under the vibrations and movements that these portable devices are subjected to during daily use. The precision of our stamped parts also ensures that they fit snugly within the compact spaces of modern electronics, contributing to the overall miniaturization and efficiency of the devices.

Applications of Spring Steel Stamped Parts in the Automotive and Household Sectors

In the automotive industry, our Spring Steel Stamped Parts are widely used for various purposes. Metal clips made from nickel – plated spring steel are used to secure hoses, wires, and other components under the hood. The corrosion resistance of the plating protects the clips from the harsh automotive environment, which includes exposure to engine oils, road salts, and high temperatures.

In household applications, our metal clips find use in appliances, furniture, and DIY projects. They are used to hold parts together, provide adjustable connections, or serve as decorative elements. The attractive surface finish of the nickel – plated clips adds an aesthetic touch to household items, while their durability ensures that they can withstand regular use and handling. Whether it’s in a kitchen appliance or a piece of furniture, our Spring Steel Stamped Parts offer reliable and functional solutions.

Future Prospects of Custom Nickel Plated Spring Steel Stamped Parts

Looking to the future, we are highly optimistic about the prospects of our Custom Nickel Plated Spring Steel Stamped Parts. As industries continue to evolve and new technologies emerge, the demand for high – quality, customized metal components will only increase. The growth of electric vehicles, the development of smart home devices, and the increasing focus on sustainable manufacturing will all drive the need for more advanced and reliable stamped parts.

We are committed to continuous research and development to stay at the forefront of this evolving market. Our team will explore new spring steel alloys, innovative nickel plating techniques, and advanced bending stamping methods to further enhance the performance, durability, and functionality of our products. By investing in cutting – edge technology and maintaining a focus on quality, we aim to meet the evolving needs of our clients across various industries and remain a leading provider of Custom Nickel Plated Spring Steel Stamped Parts.