Introduction to Spring Steel Stamped Parts in Automotive Applications

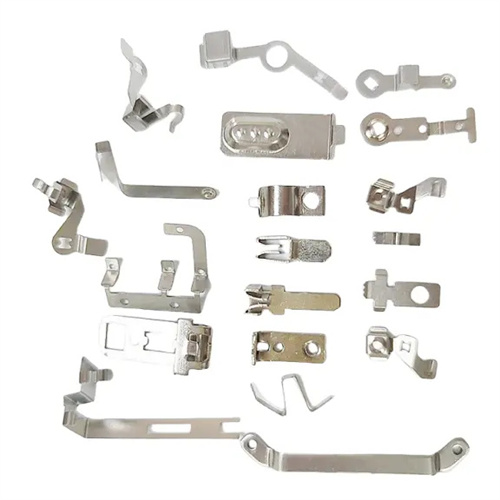

As a team deeply involved in the automotive manufacturing and component production, we understand the critical role that Spring Steel Stamped Parts play in modern vehicles. In the automotive industry, where reliability, performance, and safety are of utmost importance, components with high – cycle performance are indispensable. Spring steel, renowned for its excellent elasticity, strength, and fatigue resistance, is the ideal material for creating stamped parts that can endure repeated stress and deformation over extended periods.

Our Spring Steel Stamped Parts are designed to meet the demanding requirements of automotive applications. Whether it’s for suspension systems, engine components, or other vital parts of a vehicle, these parts are engineered to provide consistent performance throughout the vehicle’s lifespan. We take pride in our expertise in working with spring steel and our advanced stamping techniques, which allow us to produce parts that not only contribute to the overall functionality of vehicles but also enhance their durability and efficiency.

The Superior Advantages of Spring Steel Stamped Parts with High-Cycle Performance

We are well – aware of the superior advantages that our Spring Steel Stamped Parts with high – cycle performance offer in the automotive sector. One of the most significant benefits is the exceptional fatigue resistance of spring steel. In automotive applications, parts are often subjected to continuous vibrations, shocks, and cyclic loading. Our spring steel stamped parts can withstand these high – cycle stresses without failure, ensuring long – term reliability. This reduces the need for frequent replacements, saving both time and cost for vehicle manufacturers and end – users.

The high elasticity of spring steel also allows our stamped parts to return to their original shape after deformation, maintaining the proper functionality of automotive systems. For example, in suspension springs, the ability to absorb and release energy efficiently is crucial for a smooth and stable ride. Additionally, the strength of spring steel provides the necessary load – bearing capacity, enabling our stamped parts to support heavy components and withstand mechanical forces. These combined advantages make our Spring Steel Stamped Parts with high – cycle performance a top choice for automotive applications.

The Meticulous Fabrication Process of Spring Steel Stamped Parts

Our fabrication process for Spring Steel Stamped Parts is a highly detailed and carefully orchestrated sequence of steps. It begins with in – depth consultations with our automotive clients to fully understand their specific requirements, including the intended application, performance expectations, and any design constraints. Our team of experienced engineers then uses advanced CAD/CAM software to create detailed 3D models of the parts, optimizing the design for functionality, manufacturability, and high – cycle performance.

Once the designs are finalized, we source high – quality spring steel materials from trusted suppliers. These materials are then fed into our state – of – the – art stamping presses, which are equipped with custom – made dies. During the stamping process, we closely monitor and control parameters such as pressure, speed, and temperature to ensure consistent quality and dimensional accuracy. After stamping, the parts may undergo a series of post – processing operations, including heat treatment to enhance mechanical properties, shot peening to improve fatigue resistance, and surface finishing to protect against corrosion. Rigorous quality inspections are carried out at every stage to guarantee that each Spring Steel Stamped Part meets our strict quality standards before being delivered to the client.

Applications of Spring Steel Stamped Parts in Automotive Suspension Systems

In automotive suspension systems, our Spring Steel Stamped Parts play a vital role. Suspension springs, which are often made from spring steel, are responsible for absorbing shocks and maintaining the stability of the vehicle. Our precision – stamped suspension springs are designed to provide the right balance of stiffness and flexibility, ensuring a comfortable ride while also enhancing handling and control.

These springs can withstand the high – cycle loads generated by the vehicle’s movement over various road surfaces, from smooth highways to bumpy off – road terrains. Additionally, other stamped parts in the suspension system, such as brackets and mounts made from spring steel, provide the necessary support and connection for the springs and other components. The high – cycle performance of our Spring Steel Stamped Parts in suspension systems contributes significantly to the overall safety and performance of the vehicle, reducing the risk of component failure and improving the driving experience.

Applications of Spring Steel Stamped Parts in Engine and Transmission Components

In the engine and transmission systems of vehicles, our Spring Steel Stamped Parts are also essential. In engines, parts such as valve springs, which are critical for the proper operation of the engine’s valves, are made from spring steel. These springs need to withstand the high – frequency opening and closing motions, as well as the high temperatures and mechanical stresses within the engine. Our stamped valve springs, with their high – cycle performance, ensure reliable valve operation, contributing to the engine’s efficiency and power output.

For transmission systems, spring steel stamped parts are used in components such as clutch springs and shift forks. These parts need to endure the repeated engagement and disengagement processes, as well as the torque and forces transmitted during gear shifting. The durability and high – cycle performance of our Spring Steel Stamped Parts in engine and transmission components help to maintain the smooth operation of these systems, reducing wear and tear and extending their service life.

Future Prospects of Spring Steel Stamped Parts in the Automotive Industry

Looking to the future, we are highly optimistic about the prospects of our Spring Steel Stamped Parts in the automotive industry. As the automotive sector continues to evolve with the development of electric vehicles, autonomous driving technologies, and more stringent performance and safety regulations, the demand for high – quality, reliable components with high – cycle performance will only increase.

We are committed to continuous research and development to stay at the forefront of this evolving market. Our team will explore new spring steel alloys, innovative stamping techniques, and advanced manufacturing processes to further enhance the performance, durability, and efficiency of our Spring Steel Stamped Parts. By investing in state – of – the – art equipment and maintaining a focus on quality, we aim to meet the evolving needs of automotive manufacturers and contribute to the advancement of the automotive industry with our high – performance Spring Steel Stamped Parts.