Introduction to Precision Stamped Parts in Metal Work Laser Cutting Service

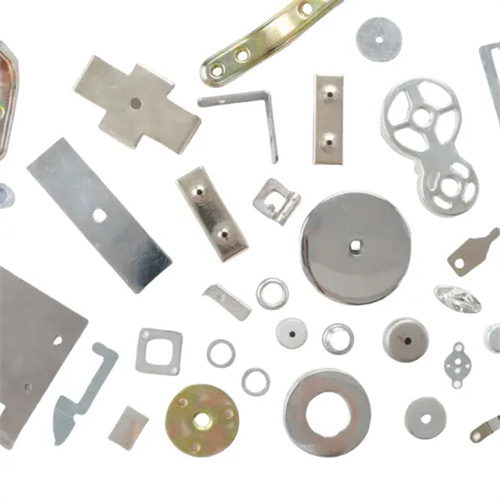

As a team dedicated to providing top – tier metal fabrication solutions, we recognize the significant role that Precision Stamped Parts play in our metal work laser cutting service. Laser cutting, with its unparalleled precision and versatility, combined with our expertise in precision stamping, offers a comprehensive approach to creating high – quality metal components. This service caters to the diverse needs of industries where accuracy, consistency, and customization are of utmost importance.

In today’s competitive manufacturing landscape, the demand for intricate metal parts is ever – increasing. Our ability to integrate precision stamping with laser cutting technology allows us to transform raw metal materials into precisely engineered components. Whether it’s for small – scale prototyping or large – volume production, we take pride in our capacity to deliver Precision Stamped Parts that meet and exceed the expectations of our clients across various sectors.

The Unmatched Advantages of Precision Stamped Parts in Metal Work Laser Cutting Service

We are well – aware of the unmatched advantages that our Precision Stamped Parts, produced through our metal work laser cutting service, offer. One of the primary benefits is the exceptional precision achievable with laser cutting. The use of laser beams enables us to create parts with incredibly tight tolerances, down to the micron level. This precision ensures that our stamped parts fit seamlessly into complex assemblies, reducing the risk of errors during installation and enhancing overall performance.

Another significant advantage is the flexibility in design. Laser cutting allows us to create intricate shapes and patterns that would be challenging or impossible to achieve with traditional cutting methods. This flexibility, combined with our precision stamping capabilities, gives our clients the freedom to design unique and customized metal components. Additionally, the non – contact nature of laser cutting minimizes material distortion, preserving the integrity of the metal and ensuring consistent quality across all our Precision Stamped Parts. The efficiency of the process also reduces production time and waste, making our service both cost – effective and environmentally friendly.

The Detailed Process of Precision Stamped Parts in Metal Work Laser Cutting Service

Our process for creating Precision Stamped Parts through metal work laser cutting service is a highly detailed and carefully coordinated sequence. It begins with in – depth consultations with our clients to fully understand their project requirements, including design specifications, material preferences, and performance expectations. Our team of experienced engineers then utilizes advanced CAD/CAM software to create detailed 3D models of the parts, optimizing the design for both laser cutting and stamping operations.

Once the designs are finalized, we source high – quality metal materials, such as steel, stainless steel, aluminum, or copper, from trusted suppliers. The metal sheets are first processed using our state – of – the – art laser cutting machines. The laser beam precisely cuts the metal according to the design, creating the base shape of the part. After laser cutting, the parts are transferred to our precision stamping presses, where custom – made dies are used to perform additional operations, such as bending, forming, and embossing. Post – processing steps, including deburring, surface finishing, and quality inspection, are carried out to ensure that each Precision Stamped Part meets our stringent quality standards before being delivered to the client.

Applications of Precision Stamped Parts in the Automotive Industry

In the automotive industry, our Precision Stamped Parts produced through metal work laser cutting service are widely utilized and play a crucial role. Laser – cut and precision – stamped parts are used in various components, from engine brackets and transmission parts to body panels and interior trims. The high precision of these parts ensures proper fit and function, reducing vibrations and enhancing the overall performance and safety of the vehicle.

For example, engine brackets need to withstand high temperatures and mechanical stresses while maintaining precise alignment. Our laser – cut and stamped brackets, with their accurate dimensions and strong structural integrity, meet these requirements. In body panel manufacturing, the ability to create complex shapes through laser cutting, followed by precision stamping for added strength, allows for the production of lightweight yet robust panels. These parts contribute significantly to the aerodynamic design and fuel efficiency of modern automobiles.

Applications of Precision Stamped Parts in the Electronics and Aerospace Sectors

In the electronics industry, our Precision Stamped Parts are essential for the production of a wide range of devices. Laser – cut and precision – stamped metal components are used in enclosures, heat sinks, connectors, and circuit board shields. The precision of these parts is crucial for ensuring proper fit and functionality, especially in the miniaturized and highly integrated world of electronics.

For aerospace applications, where weight reduction and high strength are critical, our Precision Stamped Parts offer the perfect solution. Laser cutting enables the creation of intricate and lightweight designs, while precision stamping adds the necessary strength and durability. These parts are used in aircraft structures, engine components, and avionics systems, where reliability and performance are non – negotiable. Our ability to produce parts with tight tolerances and high precision ensures that they meet the stringent requirements of the aerospace industry.

Future Prospects of Precision Stamped Parts in Metal Work Laser Cutting Service

Looking to the future, we are highly optimistic about the prospects of our Precision Stamped Parts in metal work laser cutting service. As technology continues to advance and industries become more competitive, the demand for high – quality, customized, and precisely engineered metal components will only increase. The growth of electric vehicles, the development of 5G technology, and the expansion of the aerospace industry will all drive the need for innovative and advanced metal fabrication solutions.

We are committed to continuous research and development to stay at the forefront of this evolving market. Our team will explore new materials, such as advanced composites and lightweight alloys, and integrate them with our laser cutting and precision stamping technologies. We will also invest in cutting – edge equipment and software to further enhance the precision, efficiency, and flexibility of our service. By maintaining our focus on quality and innovation, we aim to meet the evolving needs of our clients across various industries and remain a leading provider of Precision Stamped Parts through metal work laser cutting service.