Introduction to Custom Stamped Parts of Precision Metal Stamped Parts Fabrication

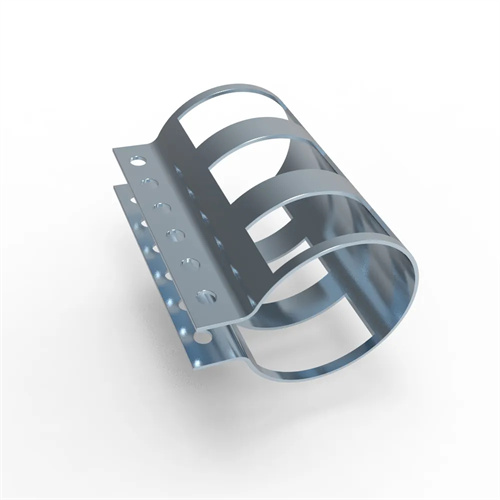

As a team deeply entrenched in the metal fabrication industry, we understand the paramount importance of precision in delivering high – quality components. Custom Stamped Parts resulting from our precision metal stamped parts fabrication services are engineered to meet the exacting standards of diverse industries. Precision is not just a feature; it’s the cornerstone of our manufacturing philosophy, enabling us to create metal components that are not only functional but also tailored to the unique requirements of each client.

In today’s competitive market, where technology – driven advancements demand ever – more accurate parts, our custom – stamped solutions have become indispensable. Whether it’s for the automotive, aerospace, electronics, or medical sectors, the need for precision – made metal components continues to grow. We take pride in our ability to leverage cutting – edge techniques and state – of – the – art equipment to produce Custom Stamped Parts that redefine what’s possible in metal fabrication, ensuring our clients receive components that offer superior performance and reliability.

The Unparalleled Advantages of Custom Stamped Precision Metal Stamped Parts

We are acutely aware of the unparalleled advantages that our Custom Stamped Precision Metal Stamped Parts bring to the table. One of the most significant benefits is the high level of accuracy we can achieve. Our advanced stamping technologies, combined with meticulous engineering, allow us to produce parts with extremely tight tolerances. This precision ensures a perfect fit within complex systems, reducing the risk of mechanical failures and enhancing overall functionality.

Another key advantage lies in the cost – effectiveness of our custom – stamped solutions. Through precision metal stamped parts fabrication, we can optimize material usage, minimizing waste and reducing production costs. Despite the high level of precision, our efficient manufacturing processes enable us to offer competitive pricing, making our Custom Stamped Parts an attractive option for businesses of all sizes. Additionally, the repeatability of our stamping processes guarantees consistent quality across large production runs, providing our clients with the confidence that each part will perform as expected.

The Elaborate Fabrication Process of Custom Stamped Parts

Our fabrication process for Custom Stamped Parts is an elaborate and highly coordinated sequence of steps. It commences with in – depth consultations with our clients to fully understand their project requirements, including the intended application, performance expectations, and any design constraints. Our team of experienced engineers then utilizes advanced CAD/CAM software to create detailed 3D models of the parts, optimizing the design for both functionality and manufacturability.

Once the designs are finalized, we source high – quality metal materials from trusted suppliers. These materials are then fed into our state – of – the – art stamping presses, which are equipped with custom – made dies crafted with utmost precision. During the stamping process, we closely monitor and control a multitude of parameters such as pressure, speed, and temperature to ensure consistent quality and dimensional accuracy. After stamping, the parts undergo a series of post – processing operations, including deburring, heat treatment, and surface finishing, to enhance their mechanical properties, durability, and appearance. Rigorous quality inspections are carried out at every stage to guarantee that each Custom Stamped Part meets our exacting standards before being delivered to the client.

Applications of Custom Stamped Parts in the Automotive Industry

In the automotive industry, our Custom Stamped Parts play a crucial role in enhancing vehicle performance and safety. Precision metal stamped parts are used in a wide range of applications, from engine components to body structures. For example, in engine manufacturing, our custom – stamped parts are utilized in creating brackets, connectors, and housings that need to withstand high temperatures, vibrations, and mechanical stresses. The precision of these parts ensures proper alignment and fit, contributing to the engine’s efficiency and longevity.

In the vehicle’s body structure, our custom – stamped metal components are essential for creating lightweight yet robust frames. The tight tolerances achieved through our precision fabrication process allow for seamless integration of various parts, reducing noise, vibration, and harshness. Additionally, in safety – critical systems such as airbag deployment mechanisms and seatbelt anchors, the accuracy and reliability of our Custom Stamped Parts are non – negotiable, ensuring the safety of passengers in the event of an accident.

Applications of Custom Stamped Parts in the Medical and Aerospace Sectors

In the medical and aerospace sectors, where precision and reliability are of utmost importance, our Custom Stamped Parts have proven to be invaluable. In the medical field, our precision – made metal components are used in surgical instruments, diagnostic equipment, and implantable devices. The high level of accuracy in our stamping process ensures that these parts meet strict biocompatibility and performance standards, contributing to the effectiveness and safety of medical procedures.

In the aerospace industry, our Custom Stamped Parts are utilized in aircraft structures, engines, and avionics systems. The ability to produce parts with precise dimensions and exceptional strength is crucial for ensuring the integrity and reliability of aerospace equipment. Whether it’s components for the fuselage that need to withstand high – altitude pressures or parts for the engine that operate in extreme temperatures, our precision metal stamped parts fabrication services deliver components that meet the rigorous demands of this challenging industry.

Future Prospects of Custom Stamped Precision Metal Stamped Parts Fabrication

Looking to the future, we are highly optimistic about the prospects of Custom Stamped Precision Metal Stamped Parts Fabrication. As technology continues to evolve, with the emergence of advanced manufacturing techniques like 3D printing and the Internet of Things (IoT), the demand for precision – engineered metal components will only increase. These emerging trends will require even more accurate, customized, and intelligent parts to support innovative applications.

We are committed to continuous research and development, investing in new technologies and upgrading our manufacturing processes to stay at the forefront of the industry. Our team will explore new materials, innovative stamping techniques, and digital manufacturing solutions to further enhance the precision and performance of our Custom Stamped Parts. By embracing these advancements and maintaining our focus on quality, we aim to meet the evolving needs of our clients across various industries and remain a leading provider of precision metal stamped parts fabrication services.