Introduction to Custom Stamped Parts of Copper Beryllium Brass

As a team with extensive expertise in metal fabrication, we recognize the unique value that Custom Stamped Parts of copper beryllium brass bring to various industries. Small metal stamped fabrication using these materials is a specialized process that allows us to create intricate, high – quality components tailored to our clients’ specific needs. Copper, beryllium, and brass each possess distinct properties, and when combined, they offer a remarkable blend of electrical conductivity, mechanical strength, and corrosion resistance.

In today’s competitive market, where precision and reliability are paramount, our custom – stamped parts have become a sought – after solution. Whether it’s for the electronics, automotive, or aerospace sectors, the demand for small – scale, high – performance metal components continues to grow. We take pride in our ability to leverage the characteristics of copper beryllium brass through our advanced stamping techniques, delivering Custom Stamped Parts that not only meet but exceed industry standards in terms of quality and functionality.

The Exceptional Properties of Custom Stamped Parts Made from Copper Beryllium Brass

We are well – versed in the exceptional properties that make Custom Stamped Parts crafted from copper beryllium brass stand out. Copper, renowned for its excellent electrical conductivity, forms the basis for ensuring efficient power and signal transmission in components. This is especially crucial in electronics, where even the slightest increase in resistance can disrupt the performance of a device. Beryllium, on the other hand, adds significant strength and hardness to the alloy, enabling our custom – stamped parts to withstand heavy mechanical stresses, vibrations, and repeated use.

Brass contributes its own set of advantages, including good corrosion resistance and malleability. The combination of these three materials in our Custom Stamped Parts results in components that can endure harsh environments, from the humid conditions in marine applications to the high – temperature and high – pressure settings in automotive engines. The unique properties of copper beryllium brass also allow for the creation of complex geometries through our small metal stamped fabrication process, providing our clients with parts that are both highly functional and precisely tailored to their requirements.

The Meticulous Fabrication Process of Custom Stamped Parts

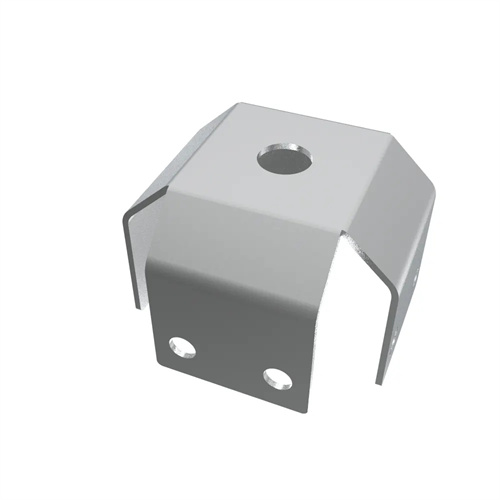

Our fabrication process for Custom Stamped Parts of copper beryllium brass is a highly detailed and carefully executed sequence of steps. It begins with in – depth consultations with our clients to fully understand their project specifications, performance expectations, and any design constraints. Our team of experienced engineers then utilizes advanced CAD/CAM software to design precise 3D models of the parts, optimizing the design for manufacturability, functionality, and cost – effectiveness.

Once the designs are finalized, we source high – quality copper beryllium brass materials from trusted suppliers. These materials are then fed into our state – of – the – art stamping presses, which are equipped with custom – made dies. During the stamping process, we closely monitor and control parameters such as pressure, speed, and temperature to ensure consistent quality and dimensional accuracy. After stamping, the parts undergo a series of post – processing operations, including deburring to remove sharp edges, heat treatment to enhance mechanical properties, and surface finishing to improve corrosion resistance and appearance. Rigorous quality inspections are carried out at every stage to guarantee that each Custom Stamped Part meets our exacting standards before it leaves our facility.

Applications of Custom Stamped Parts in the Electronics Industry

In the electronics industry, our Custom Stamped Parts of copper beryllium brass play a vital role. In smartphones, tablets, and laptops, these parts are used in connectors, terminals, and internal circuit board components. The high electrical conductivity of copper ensures reliable data and power transfer, while the strength and durability provided by beryllium and brass allow the parts to withstand the rigors of repeated connection and disconnection.

For more specialized electronic devices such as high – frequency communication equipment and aerospace electronics, our custom – stamped components are essential. Their ability to maintain stable electrical performance under extreme conditions, along with their resistance to electromagnetic interference, makes them ideal for these applications. The precision of our small metal stamped fabrication process also enables us to create parts with tight tolerances, ensuring a perfect fit within the compact and complex designs of modern electronic devices.

Applications of Custom Stamped Parts in the Automotive and Aerospace Sectors

In the automotive and aerospace sectors, where safety and performance are non – negotiable, our Custom Stamped Parts of copper beryllium brass are highly valued. In automobiles, these parts are used in engine components, electrical systems, and safety – critical structures. The strength and heat resistance of beryllium – enhanced brass make it suitable for engine – related parts that need to withstand high temperatures and mechanical stress.

In the aerospace industry, our custom – stamped parts are utilized in aircraft wiring systems, connectors, and structural components. The combination of corrosion resistance, high strength, and lightweight properties of copper beryllium brass is crucial for ensuring the reliability and longevity of aerospace equipment, even in the most challenging environments. Whether it’s withstanding the vibrations during flight or resisting the corrosive effects of airborne particles, our Custom Stamped Parts provide the durability and performance that these industries demand.

Future Prospects of Custom Stamped Parts Copper Beryllium Brass

Looking to the future, we are highly optimistic about the prospects of our Custom Stamped Parts made from copper beryllium brass. As technology continues to advance, with the growth of 5G, the Internet of Things (IoT), and electric vehicles, the demand for high – performance, precision – engineered metal components will only increase. These emerging technologies require parts that can handle higher electrical loads, offer better thermal management, and provide enhanced reliability.

We are committed to continuous research and development to stay at the forefront of this evolving market. Our team will explore new alloys, innovative stamping techniques, and advanced design methodologies to further enhance the performance of our Custom Stamped Parts. By investing in cutting – edge equipment and maintaining our focus on quality, we aim to meet the evolving needs of our clients across various industries and remain a leading provider of small metal stamped fabrication using copper beryllium brass.