Beryllium bronze plates and strips

Beryllium bronze sheet and strip are high-performance alloys based on a copper matrix with 1.7-2.5% beryllium and small amounts of elements such as nickel and cobalt. Their excellent mechanical properties, elasticity, electrical conductivity, and corrosion resistance have made them a key component in the electronics, aerospace, and precision machinery industries. After solution aging treatment, these materials achieve tensile strengths of 1200-1400 MPa and hardnesses as high as HRC40-45, while maintaining an elongation of 10-15%, making them one of the strongest copper alloys currently available. Compared to other copper alloys, beryllium bronze exhibits reduced elastic hysteresis, a long fatigue life, and stable elastic properties under long-term alternating loads, making it particularly suitable for the manufacture of high-precision elastic components. Beryllium bronze sheet and strip products typically range in thickness from 0.1-5 mm and widths up to 1000 mm, with a surface finish of Ra ≤ 0.8 μm, meeting the stringent requirements of precision machining.

The production process of beryllium bronze plates and strips is complex and technically demanding, with the core focus being precise control of composition and heat treatment. First, high-purity electrolytic copper (purity ≥99.95%), metallic beryllium, and alloying elements are smelted in a vacuum induction furnace. The deviation in beryllium content is strictly controlled (≤0.05%) to prevent the formation of brittle phases. The smelted ingots undergo homogenization annealing (780-820°C) and hot rolling to reduce the thickness to 5-10mm. The rolling temperature is controlled at 700-750°C, with the reduction per pass not exceeding 30% to avoid cracking due to work hardening. The cold rolling stage uses multiple passes to gradually reduce the thickness to the target size, with soft annealing (650-700°C) required in between to restore plasticity. The finished plates and strips need to undergo solution treatment (780-800℃ water quenching) and aging treatment (300-320℃) to achieve strengthening by precipitating dispersed beryllium copper compounds. Finally, they are straightened, slit and precisely tested to ensure that the dimensional tolerance (±0.01mm) and performance indicators meet the standards.

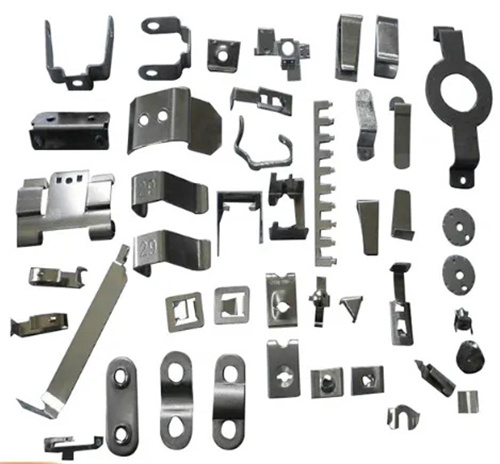

In the electronics and electrical fields, beryllium copper plates and strips are core materials for high-precision connectors and switches. The spring clips in smartphone SIM card connectors are made of 0.1-0.3mm thick beryllium copper strip. After being stamped, they possess stable elasticity and conductivity, with a plug-in/out lifespan exceeding 100,000 cycles. A certain brand of mobile phone, using this material, has seen a 60% reduction in connector failure rates. The contact springs of high-voltage circuit breakers are made of 1-2mm thick beryllium copper plates. They maintain stable contact pressure during high current switching and disconnection, with a breaking speed exceeding 10m/s. In precision instruments, the elastic element of piezoelectric sensors is made of beryllium copper strip. Its excellent elasticity and conductivity enable precise conversion of pressure signals into electrical signals, with a measurement accuracy of ±0.1%.

The aerospace and military industries place even more stringent performance requirements on beryllium copper plates and strips. Aircraft landing gear proximity switch contacts are made of beryllium copper plates, which maintain stable conductivity and wear resistance in temperatures ranging from -55°C to 125°C, with a service life of up to 10,000 takeoffs and landings. Gyroscopic frames in missile guidance systems utilize 0.5-1mm thick beryllium copper strips. Their high rigidity and low magnetic permeability reduce electromagnetic interference and ensure guidance accuracy within 0.1°. In nuclear submarine communications equipment, the elastic components of waterproof sealed connectors are made of beryllium copper plates, which can withstand pressure and seawater corrosion at depths of 300 meters, ensuring smooth underwater communications.

With the development of high-end manufacturing technology, the performance of beryllium bronze plates and strips continues to improve, and their application scenarios continue to expand. Through ultrafine grain strengthening technology, manufacturers have increased the material’s fatigue strength by 15%, meeting the needs of high-frequency vibration components in aircraft engines. For the microelectronics field, ultra-thin beryllium bronze strips with a thickness of less than 0.05mm have been developed for use in chip test probes, achieving nanometer-level precision contact. Regarding environmental protection, companies are developing low-beryllium alloys (beryllium content ≤1%) to reduce health risks during processing while increasing material recovery rates to over 90%. In the future, with the development of technologies such as 5G communications and autonomous driving, the demand for high-performance beryllium bronze plates and strips will continue to grow, driving breakthroughs in production processes towards intelligent and green processes.