Commonly used aluminum and aluminum alloy foil

Commonly used aluminum and aluminum alloy foil refers to thin sheets of aluminum and aluminum alloys with a thickness between 0.006 and 0.2 mm. These foils offer excellent properties such as light weight, excellent thermal conductivity, corrosion resistance, and ease of processing, making them widely used in packaging, electronics, construction, aerospace, and other fields. Made from pure aluminum or aluminum alloy cast coils through multiple cold rolling passes, these foils are categorized by application, including packaging, industrial, and electronic. Packaging foil accounts for the largest proportion of these applications and is commonly used in the packaging of food, pharmaceuticals, cosmetics, and other products. Its excellent barrier and sealing properties effectively extend the shelf life of these products.

In terms of production technology, the manufacture of commonly used aluminum and aluminum alloy foils requires multiple steps, including casting, cold rolling, and annealing. First, aluminum ingots or aluminum alloy ingots are melted and then rolled through a casting mill into cast coils with a thickness of 6-10 mm. The rolling temperature and cooling rate must be strictly controlled during the casting process to ensure uniform microstructure of the cast coils. Subsequently, the cast coils undergo multiple cold rolling passes, with each pass achieving a rolling reduction of 50%-70%, until the desired thickness is reached. For ultra-thin aluminum foils with a thickness of less than 0.01 mm, a duplex rolling process is used, where two sheets of aluminum foil are stacked and rolled together to avoid breakage during single sheet rolling. Intermediate annealing is also required during the rolling process to eliminate work hardening, restore the material’s plasticity, and ensure smooth subsequent rolling. The final product undergoes slitting and annealing to achieve the desired dimensions and mechanical properties.

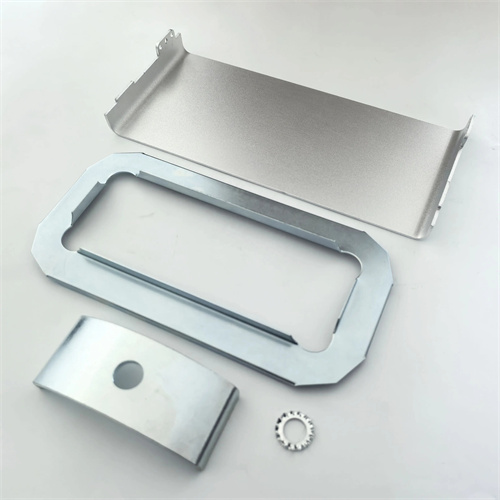

From a material perspective, different grades of aluminum and aluminum alloy foil have different performance characteristics and are suitable for different applications. Pure aluminum foil (such as 1060 and 1100) has extremely high purity (over 99%) and good ductility, making it easy to process and shape, and is commonly used in food packaging and daily necessities. Aluminum alloy foil (such as 8011 and 3003) has enhanced strength and corrosion resistance by adding elements such as manganese and iron, making it suitable for applications with certain strength requirements, such as pharmaceutical packaging and cigarette packaging. Series 5 aluminum alloy foil (such as 5052) has higher strength and good seawater corrosion resistance, and is commonly used in industrial applications such as heat sinks and capacitor casings. Furthermore, a wide variety of surface treatment techniques are available for aluminum foil, including coating, printing, and embossing, further expanding its application range.

Across a range of applications, the advantages of commonly used aluminum and aluminum alloy foil are fully utilized. In the packaging sector, aluminum foil, due to its excellent barrier properties (oxygen, water, and light), is widely used in the packaging of foods such as instant noodles, chocolate, and milk powder, as well as in blister packaging for pharmaceuticals such as tablets and capsules, effectively preventing oxidation and deterioration. In the electronics sector, aluminum foil is used in capacitor electrodes and battery tabs, enhancing the performance of electronic components thanks to its excellent conductivity and ductility. In the construction sector, aluminum foil is often used as a veneer for thermal insulation materials, providing insulation by reflecting thermal radiation. In the aerospace sector, aluminum foil, due to its lightweight properties, is used in aircraft interiors and thermal control coatings for spacecraft. With growing environmental awareness, the development of biodegradable aluminum foil and recycling technologies has further enhanced the environmental friendliness of aluminum foil.

Industry trends indicate that the production of commonly used aluminum and aluminum alloy foils is moving toward thinner, more functionalized, and higher-end designs. Through the development of new rolling equipment and processes, ultra-thin aluminum foils as thin as 0.004 mm can now be produced, meeting the demands of high-end electronics. The research and application of functionalized aluminum foils, such as antibacterial, self-healing, and high-barrier foils, have become a hot topic, expanding their applications in medical and military applications. Furthermore, the industry is actively promoting green production, reducing energy consumption and pollutant emissions during production by adopting clean energy and optimizing rolling oil recovery systems. In the future, with the development of new energy and new materials industries, demand for high-performance aluminum and aluminum alloy foils will continue to grow, driving the industry to achieve greater breakthroughs in material research and development, process innovation, and product diversification.