Classification of wedges and sliders

The classification of cams and sliders is determined based on factors such as their structure, direction of motion, force applied, and application scenario. Different types of cams and sliders perform different functions in the mold and adapt to different forming process requirements. Appropriate classification helps select the appropriate cam and slider type for specific working conditions, improving mold design efficiency and operational reliability. Common classification methods include classification by bevel angle, direction of motion, structure, force applied, and application scenario. Each classification method has its own unique characteristics and scope of application.

The most common classification method for cams is by bevel angle. The bevel angle directly affects the force transfer efficiency and travel between the cam and the slider. Common angles include 15°, 20°, 30°, and 45°. Smaller angles increase the force amplification factor (force transfer coefficient = 1/sinα), but also reduce the slider’s travel. Larger angles decrease the force amplification factor and increase the travel. For example, a 15° cam has a force transfer coefficient of approximately 3.86, making it suitable for applications requiring high force and short travel (such as precision stamping). A 45° cam has a force transfer coefficient of approximately 1.41, making it suitable for applications requiring high travel and medium force (such as bending). The selection process requires balancing force and travel requirements. For forming high-strength materials, cams between 15° and 30° are typically used to achieve sufficient force.

Sliders can be categorized by their direction of movement as horizontal, inclined, and compound-motion sliders. Horizontal sliders move horizontally and are suitable for processes such as lateral bending and side hole stamping. Their horizontally arranged guide rails offer a simple structure and high motion precision. For example, horizontal sliders are commonly used in side panel bending dies for automotive panels. Inclined sliders move at an angle (usually 30°-60°) to the horizontal and are suitable for oblique hole stamping or oblique bending. They require use with angled wedges of corresponding angles. For example, 30° inclined sliders are used in the oblique flanging process for air conditioner casings. Compound-motion sliders achieve simultaneous horizontal and vertical motion, achieving complex trajectory motion through the coordinated action of multiple sets of inclined wedges and guide rails. These sliders are suitable for forming irregularly shaped parts, such as the complex curved surfaces of motorcycle fuel tanks.

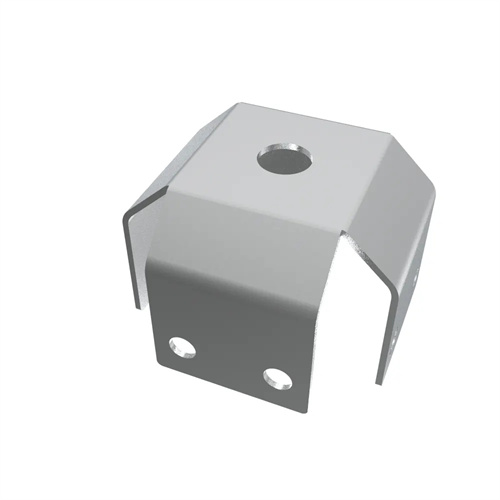

Based on their structural form, cams can be divided into integral and combined types, while sliders can be divided into integral and split types. Integral cams are machined from a single piece of material, offering excellent structural rigidity and high precision. They are suitable for applications requiring high forces and precision, but are difficult and costly to manufacture, such as the integral cams used in precision stamping dies. Combined cams are assembled from multiple parts and secured by bolts or welding, making them easy to manufacture and maintain. They are suitable for large molds or complex structures, but their rigidity is slightly lower than that of integral cams, such as the combined cams used in large automotive panel molds. Integral sliders offer a compact structure and excellent rigidity, making them suitable for small molds. Split sliders, consisting of a slider body and guide rails, facilitate adjustment of clearances and are suitable for large molds with large travels, such as the split sliders used in heavy machinery molds.

Cams and sliders can be categorized by force, light, medium, and heavy. Light-duty cams and sliders are suitable for light loads (force ≤ 50kN), such as in the stamping of electronic components. They feature compact dimensions and low weight, typically made of aluminum alloy or cast iron. Cam thicknesses range from 10-30mm, and slider weights ≤ 5kg. Medium-duty cams and sliders are suitable for moderate loads (50kN < force ≤ 300kN), such as in the bending of automotive parts. They are manufactured from carbon steel (such as 45 steel), with cam thicknesses of 30-80mm and slider weights of 5-20kg. Tempering treatment is required (hardness 28-32HRC). Heavy-duty wedges and sliders are suitable for large load applications (force > 300kN), such as stamping parts for large-scale engineering machinery. They are made of high-strength alloy steel (such as 40Cr). The thickness of the wedges is 80-200mm, and the weight of the sliders is > 20kg. They need to be quenched (hardness 40-45HRC) and reinforced with ribs to improve rigidity.

According to the application scenario, the cams and sliders can be divided into types such as stamping, bending, stretching and assembly. The cams and sliders for stamping need to have high motion accuracy and wear resistance. The end of the slider is equipped with a punch for stamping side holes or special-shaped holes, such as the side hole stamping die of the motor housing. The cams and sliders for bending need to have sufficient rigidity and stroke. The end of the slider is equipped with a bending punch for lateral or oblique bending, such as the side bending die of the car door frame. The cams and sliders for stretching need to be equipped with a pressing device to prevent the material from wrinkling. They are suitable for stretching of complex curved surfaces, such as the stretching die of the washing machine barrel. The cams and sliders for assembly are used for automatic assembly of molds or picking and placing of workpieces. They have fast movement speed and high positioning accuracy, such as the workpiece turning device in the automated production line.

Different types of cams and sliders have their own application scopes. Design selection should be based on a comprehensive consideration of the forming process, load size, travel range, and precision requirements. For example, a 15° integral lightweight cam and horizontal slider are used for side hole stamping of precision electronic parts; while a 30° combined heavy-duty cam and tilt slider are used for bending automotive beams. With the advancement of mold technology, new types of cams and sliders (such as hydraulically driven cams and servo-controlled sliders) are constantly emerging, and their classification is also expanding, providing more options for complex forming processes.