Multi-station progressive die design waste and process waste

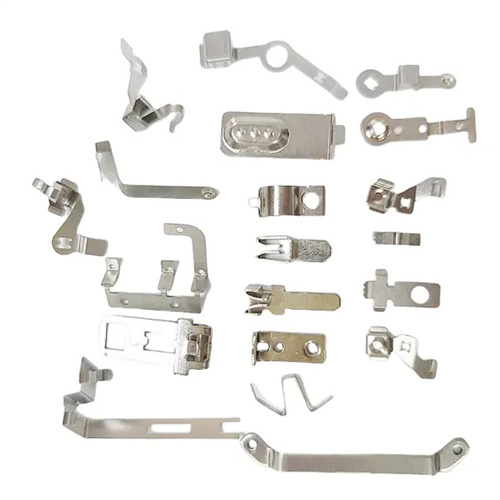

Scrap management in multi-station progressive die design is a key factor affecting material utilization and production costs. Scrap can be divided into design waste and process waste, each with different causes and control methods. Design waste is unavoidable, determined by part shape and layout, such as overlap between parts and excess material at the edge of the strip. Process waste, on the other hand, is necessary to ensure the smooth progress of the stamping process, such as waste from locating holes, side edge punching, and transition waste between process steps. Properly controlling the ratio of these two types of waste can maximize material utilization while ensuring stamping quality.

Design scrap is mainly generated by the geometric shape and layout of the parts, and its amount depends on the regularity of the part shape and the compactness of the layout. For parts with regular shapes such as circles and squares, design waste mainly comes from the overlap between parts and the excess material at the edge of the material. This can be significantly reduced by optimizing the layout method (such as staggered layout and opposite layout). For example, for circular parts with a diameter of 10mm, staggered layout can reduce design waste by 20%-30% compared with straight layout. For special-shaped parts (such as triangles and irregular curves), design waste is usually high because it is difficult to arrange the parts closely. It is necessary to reduce waste by rotating the part angle (oblique arrangement) or splitting the part structure (combined arrangement). For example, if triangular parts are rotated 60° and then arranged, the material utilization rate can be increased from 60% to 75%. The control of design waste must be considered in the part design stage. By optimizing the part shape (such as increasing fillet and reducing sharp corners), conditions are created for reducing waste in subsequent layout.

Process waste is necessary to ensure the proper functioning of the stamping process. Its quantity is closely related to process requirements and mold structure. Positioning waste is the most common type of process waste. This includes the distance waste from side blade punching and the positioning hole waste from pilot pin punching. The width of the side blade waste is equal to the feed distance and the length is the same as the strip width. The diameter of the pilot pin positioning hole is typically 3-8mm, determined by the strip thickness. Process waste generated during the forming process includes flange excess material after drawing and process ears after bending. For example, during the drawing process of a flanged cylindrical part, 5%-10% of the flange excess material must be reserved for subsequent shaping. This excess material is ultimately removed as process waste. While process waste increases material consumption, it is a necessary trade-off for ensuring stamping accuracy and stability and should not be blindly reduced. For example, if the positioning hole waste is too small, it will lead to unreliable positioning of the pilot pin, affecting part accuracy.

Scrap handling and removal are crucial aspects of multi-station progressive die design, directly impacting production efficiency and die life. Long strips of scrap (such as side-cut scrap and continuous punching scrap) require a scrap cutter to cut them into 300-500mm segments for easy removal and recycling. For scrap (such as punching scrap), a drain hole 5-10mm larger than the scrap material should be provided at the bottom of the die to ensure a smooth drop. For larger process scrap (such as flange residue after deep drawing), a scrap chute should be installed on the side of the die to remove the waste by gravity or compressed air. The scrap handling device should be designed to avoid interference with the feed mechanism and the formed part. For example, the scrap cutter should be positioned away from the forming area of the strip, and the cutting action should be synchronized with the stamping cycle to prevent scrap accumulation and die jamming.

Balancing design waste and process waste is key to improving material utilization. Design optimization should be used to reduce unnecessary waste while ensuring stamping quality. Design waste can be optimized using computer-aided nesting software (such as nesting) to find the optimal arrangement of parts. For example, software-optimized nesting of an electronic connector reduced design waste from 25% to 15%. Process waste can be reduced through improved process methods, such as using no-side-edge positioning (using only guide pins) to reduce side-edge waste and using a continuous deep drawing process to reduce flange excess. However, it is important to note that reducing process waste should not come at the expense of stamping stability. For example, the diameter of the guide pin positioning hole should not be too small, otherwise it will affect positioning accuracy. Reducing side-edge waste may also lead to decreased spacing accuracy and increased part dimensional fluctuation.

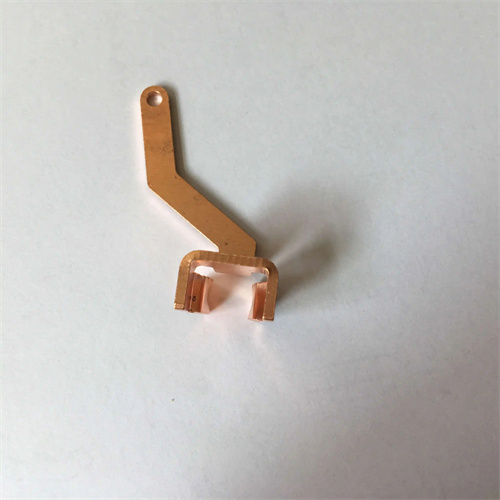

The recycling and utilization of waste materials is an important component of green manufacturing, and the design of multi-station progressive dies needs to consider the recyclability of waste materials. Waste materials of the same material (such as pure copper scrap and low-carbon steel scrap) need to be collected and sorted to facilitate re-melting. For scrap materials with higher value (such as titanium alloy and stainless steel), dedicated recycling channels need to be set up to reduce waste. During layout design, waste materials can be designed into regular shapes to improve recycling efficiency. For example, side blade scrap can be designed into a rectangular shape to facilitate packaging and transportation. In addition, waste can be reused through process innovation. For example, stamping scrap can be used as raw material for another small part, achieving cascade utilization of materials and reducing overall production costs. Through the scientific management of design waste and process waste, multi-station progressive dies can achieve good economic and environmental benefits while ensuring production efficiency and product quality.