Design of main structural parts of multi-station progressive die

The key structural components of a multi-station progressive die include the die base, working parts, positioning elements, discharge devices, and guides. The design quality of these components directly determines the precision, rigidity, and service life of the die. Each component has its own specific function and design requirements, requiring targeted design based on the overall die layout, stamping process, and production conditions to ensure coordinated operation of all components and achieve efficient and precise stamping.

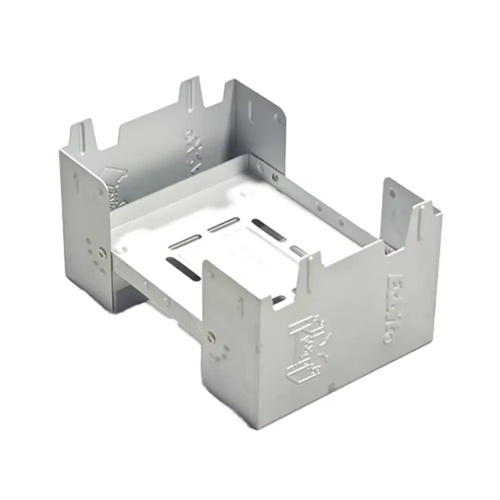

The die base is the foundation of a multi-station progressive die, used to mount and secure components and withstand the full loads of the stamping process. Therefore, it must possess sufficient rigidity and strength. The die base consists of an upper die base, lower die base, guide pins, and guide bushings. The upper and lower die bases are typically constructed of HT300 gray cast iron or ZG310-570 cast steel. Large dies (>2000mm in length) require cast steel for enhanced rigidity. The die base thickness is determined by die size and is generally 1/8-1/10 of the maximum die length. For example, for a 1000mm die, the die base thickness should be 120-150mm. Guide pins and bushings are made of carburized and quenched 20CrMnTi (hardness HRC 58-62), with a clearance of H7/h6 to ensure a guiding accuracy of ≤0.01mm. For high-speed progressive dies (>500 strokes/min), the guide pin diameter should be 20%-30% larger than for conventional dies, and auxiliary guide devices (such as guide plates) should be installed to improve guiding stability.

Working parts are the core components directly involved in stamping, including the punch, die, and dies. Their design must meet requirements for dimensional accuracy, wear resistance, and strength. Punches for blanking are made of Cr12MoV or high-speed steel W6Mo5Cr4V2. After quenching and tempering, they reach a hardness of HRC58-62, with a cutting edge radius of ≤0.02mm to prevent burrs on stamped parts. Dies are constructed of either monolithic or segmented constructions. For complex shapes, segmented construction is preferred, secured by screws and pins. The gap between segments is ≤0.005mm to avoid steps during blanking. Forming punches and dies (such as bending punches and drawing dies) must adopt a curved surface structure that matches the part shape. The material used is surface-hardened 45 steel (HRC45-50) or partially hardened Cr12MoV, ensuring both wear resistance and toughness. The installation method of the working parts must be easy to replace and adjust. The punch is pressed in or fixed with screws, and the die is embedded to ensure the positioning accuracy of ±0.005mm.

Positioning components, including side blades, guide pins, stop pins, and side pressure plates, ensure the correct positioning of the strip and parts at each workstation. These components must be designed to meet the requirements for positioning accuracy and feeding stability. Side blades, serving as coarse positioning components, have a length equal to the feed distance and a width 1.5-2 times the material thickness. Their cutting edge angle is 5°-10°, facilitating scrap separation. Guide pins, used for fine positioning, have a conical head (60° taper angle) with a clearance of 0.01-0.03mm in the positioning hole. The tail is pressed into the punch plate with a transition fit (H7/m6) to ensure a perpendicularity error of ≤0.005mm/100mm. Stop pins are available in two types: fixed and movable. Fixed stop pins limit the feeding distance, while movable stop pins are spring-controlled to extend and retract to prevent the strip from backing out. Side pressure plates correct lateral bending of the strip. Spring-adjusted pressure, typically 5-15N/cm, ensures the strip adheres tightly to the guide plate.

The unloading mechanism removes the strip or part from the punch. It consists of a stripper plate, stripper screws, and an elastic element (spring or rubber). Its design ensures uniform unloading force and flexible operation. The stripper plate is made of 45 steel or Cr12, 15-30 mm thick, with a hardness of HRC 45-50 after quenching. The clearance between the stripper plate and the punch is 0.05-0.1 mm, and the surface roughness Ra is below 1.6 μm. The stripper screws are evenly distributed on the stripper plate, with their number determined by the stripper plate area, with 1-2 screws per 100 cm², to ensure balanced force on the stripper plate. The total unloading force of the elastic element is 10%-20% of the blanking force. The spring is a cylindrical helical compression spring (material 65Mn) with a pre-compression of 20%-30% of the free length to ensure sufficient spring force throughout the punching stroke. For thin materials (t < 0.5 mm), a rubber pad should be installed on the stripper plate to prevent scratching of the strip surface.

In addition to the guide pins and guide sleeves of the mold base, the guide device also includes small guide pins and guide sleeves and guide plates, which are used to ensure the precise alignment of the punch and die, and are especially suitable for precision progressive dies. The small guide pin has a diameter of 8-16mm, and is made of GCr15 quenched (HRC60-62). The clearance with the guide sleeve is 0.005-0.01mm. It is installed between the punch fixing plate and the unloading plate. There are 4-6 small guide pins in a symmetrical distribution. The guide plate is used for guiding large punches, with a thickness of 10-20mm and a clearance of 0.01-0.02mm with the punch. It is made of wear-resistant cast iron (HT250) or bronze (ZCuSn10P1). The surface needs to be scraped and ground, and the contact area should be ≥70%. The guide device needs to be arranged close to the working part to reduce the impact of the guide error on the stamping accuracy. For example, 2-3 small guide pillars need to be set around the drawing punch to ensure that the coaxiality of the punch and die is ≤0.01mm during the drawing process. By optimizing the guide design, the service life of the die and the dimensional consistency of the stamped parts can be significantly improved.