Design of belt (strip) material guiding and floating device

The strip (or strip) material guide and float devices are key components of a strip stamping line. Their design quality directly impacts the smoothness of strip feeding, positioning accuracy, and the quality of the stamped parts. The guide device’s primary function is to guide the strip in the correct direction, preventing lateral deviation during feeding. The float device exerts upward force to maintain the strip level, preventing it from sagging or wrinkling due to its own weight or deformation from previous processes, ensuring smooth entry into the mold’s various workstations. Working together, these two devices provide reliable assurance for continuous and efficient strip stamping, a role particularly prominent in high-speed, continuous stamping.

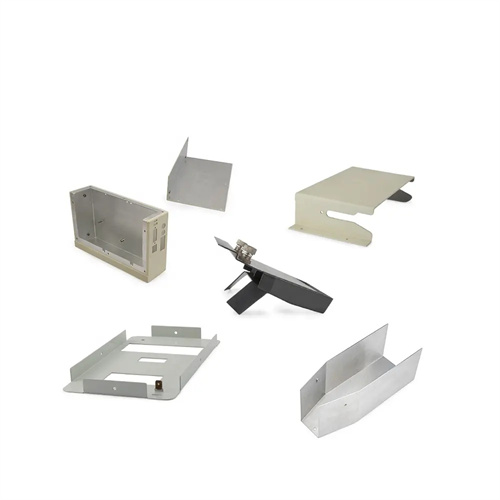

The design of the material guide device must be determined based on parameters such as the strip width, thickness, material, and feed speed. Common guide devices include guide plates, guide pins, and guide rollers. Guide plates are the most widely used guide structure and are divided into fixed and adjustable guide plates. Fixed guide plates are suitable for applications with a fixed strip width. Their spacing is 0.1-0.3mm larger than the strip width, ensuring smooth strip passage while effectively limiting lateral deviation. Adjustable guide plates, with adjustable spacing via bolts, are suitable for high-variety, small-batch production, with an adjustment range of 50-300mm. The working surface of the guide plate must be ground to a surface roughness of less than Ra1.6μm to reduce friction with the strip. For thin strips less than 0.5mm thick, the edges of the guide plate must be rounded (R0.2-R0.5mm) to prevent scratching of the strip surface.

The core design of the float mechanism is to provide uniform, adjustable lifting force to keep the strip level during feeding, preventing direct contact with the lower die surface, which could cause friction or scratches. The float mechanism typically consists of a float pin, spring, and float plate. The pin’s tip is mounted with a rolling bearing or wear-resistant block to reduce friction with the strip. The spring force must be precisely calculated based on the weight and thickness of the strip. For strips 1-3 mm thick, the spring force of a single float pin is typically 5-15 N. These pins are evenly spaced across the strip’s width, with spacing of 100-200 mm. The float height should be slightly above the lower die surface, 0.5-1 mm, to ensure the strip does not contact the mold and avoid excessive height that could cause it to sway. For strips with high surface quality requirements (such as stainless steel decorative parts), the pin’s tip should be made of polyurethane to prevent scratches.

The coordinated design of the material guide and float mechanism must consider the material’s deformation characteristics and feed path. For thin strips prone to wavy deformation, side pressure rollers should be added to the inner side of the guide plate to apply slight lateral pressure to correct the strip’s lateral curvature. Furthermore, the float mechanism should utilize densely spaced float pins, one every 50-100mm, to ensure uniform force across all parts of the strip. The material guide mechanism must maintain high consistency across multiple stations within the progressive die, with the centerline deviation of the front and rear guide plates no more than 0.02mm. Otherwise, the material will accumulate during feed. The float mechanism’s spring should be made of high-fatigue-strength piano wire (such as 65Mn) and aged to ensure stable elasticity over long-term use and prevent a decrease in float function due to spring failure.

The guide and float mechanisms for special strip materials require specialized designs. For wide strips exceeding 500mm in width, the guide mechanism should utilize segmented guide plates, each 300-500mm long, connected by guide rails for overall adjustment to prevent deformation caused by excessively long guide plates. The float mechanism should utilize a float roller instead of a float pin. The float roller should have a diameter of 20-30mm and be 50mm longer than the strip width. Mounted on a bearing block, it provides stable support while reducing frictional resistance to the strip. For strips with punched holes or notches, the float pin should be positioned away from these vulnerable areas to prevent deformation caused by the pins. Furthermore, during high-speed stamping (over 300 strokes/min), the guide and float mechanisms should be equipped with a lubrication system that sprays a small amount of oil (e.g., 5-10ml per hour) to reduce friction and wear while preventing the strip from slipping. Through refined design, the material guiding and floating devices can ensure that the strip material can be fed stably under various working conditions, laying the foundation for high-quality stamping production.