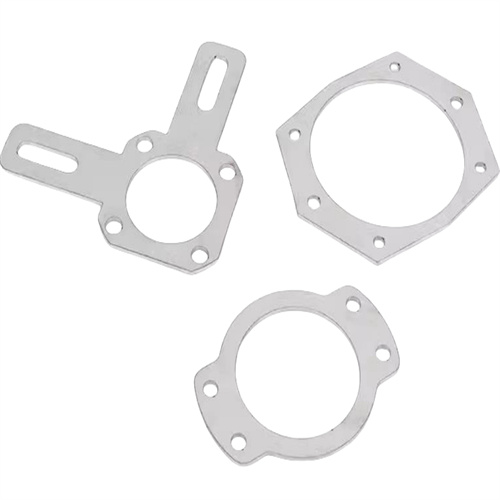

Process Calculation of Cylinder Parts with Flanges

Flanged cylindrical parts are a common part type in stamping production. Process calculations are crucial for ensuring forming quality, primarily encompassing blank size calculation, determining the number of deep drawing cycles, calculating the dimensions of each drawing cycle, and controlling flange dimensions. These calculations are based on the material’s plastic deformation patterns and the characteristics of the drawing process, combined with part structural parameters (such as barrel diameter, flange diameter, height, and wall thickness). These calculations are performed using a combination of theoretical formulas and empirical data to ensure dimensional coordination across all process steps and avoid defects such as wrinkling and cracking.

Calculating the blank size is the first step in the process calculation for flanged cylindrical parts. This calculation is based on the principle of volume invariance due to plastic deformation, which states that the blank volume is equal to the volume of the finished part (ignoring changes in plate thickness). For flangeless cylindrical parts, the blank diameter can be calculated using a formula. However, for flanged cylindrical parts, the blank diameter must take into account the material distribution between the barrel and flange. The calculation formula is: D = √ (d₁²+4d₂h+6.28r (d₂+2r)+8r²) , where D is the blank diameter, d₁ is the flange diameter, d₂ is the barrel diameter, h is the barrel height, and r is the fillet radius. When calculating, please note that if the flange diameter is large ( d₁/d₂>1.5 ), the material flow resistance in the flange must be considered, and the blank size should be adjusted through trial punching if necessary. For example, for a part with a flange diameter of 100mm, a barrel diameter of 50mm, a height of 30mm, and a fillet radius of 5mm, the calculated blank diameter is approximately 132mm. During the trial punching, it is necessary to adjust ±1-2mm according to the flatness of the flange.

The number of deep drawing cycles required is determined based on the part’s total drawing coefficient and the material’s limit drawing coefficient. The total drawing coefficient, mtotal , = d₂/D ( d₂ is the finished tube diameter, D is the blank diameter). If mtotal is greater than the material’s limit drawing coefficient (for example, the first drawing limit coefficient for mild steel is approximately 0.5-0.55 ), a single deep drawing cycle is sufficient; otherwise, multiple deep drawing cycles are required. When multiple deep drawing cycles are used, the drawing coefficients should be arranged from largest to smallest, and each drawing coefficient must be greater than the corresponding limit drawing coefficient. For example, a part with a total drawing coefficient of 0.35 requires three deep drawing cycles, with the draw coefficients for each cycle being 0.55 , 0.7 , and 0.9 ( 0.55 × 0.7 × 0.9 ≈ 0.346 ≈ 0.35 ). The number of deep drawing cycles also needs to consider flange formation. If the flange diameter is large, flange allowance should be reserved in the intermediate process, and the final shaping process should be used to achieve the designed dimensions.

Dimensional calculations for each drawing pass include determining the barrel diameter, height, flange diameter, and fillet radius. During the initial drawing, the barrel diameter d₂₁ = m₁ × D ( m₁ is the initial drawing coefficient), and the height h₁ = (D² – d₁₁²)/(4d₂₁) – 0.5 (r₁ + r₂) . ( d₁₁ is the flange diameter after the initial drawing.) The flange diameter d₁₁ is generally slightly larger than the finished flange diameter d₁ to allow for subsequent shaping. The barrel diameter for subsequent drawing passes, d₂ₙ = mₙ × d₂ₙ₋₁ . The height is calculated based on the principle of constant volume, ensuring that the barrel wall does not become excessively thinned after each drawing. The fillet radius should be gradually reduced. The fillet radius of the first drawing die is rconcave₁ = (5-10) t ( t is the material thickness), and the fillet radius of the punch is rconvex₁ = (0.7-1) rconcave₁ . The fillet radius of the last drawing should be close to the finished product size. If necessary, the design requirements can be met through the shaping process.

Process calculations for the flange require a focus on controlling its diameter and flatness. For flanges with stringent requirements, a dedicated shaping process is required in the later stages of deep drawing. This process uses the flat pressing action of the punch and die to eliminate any wavy edges. The flange diameter during shaping should be 0.5-1mm smaller than the finished product size, achieving the designed dimensions through minimal material flow. The shaping force should be 1.5-2 times the drawing force to ensure a smooth flange. For larger flange diameters ( d₁/d₂ > 2 ), the blank holder force must be controlled during the drawing process to prevent wrinkling. The blank holder force Fpressure = K × π × (d₁² – d₂²) × q ( K is the blank holder force coefficient, q is the unit blank holder force, and for mild steel, it is 2-3 MPa ).

Verification and adjustment of process calculations are crucial for ensuring production feasibility. By making simple molds for trial punching, the dimensions of the parts after each process are measured and compared with the calculated values. If cracks are detected in the cylinder wall, the drawing coefficient of the corresponding process needs to be increased; if wrinkling occurs, the blank holder force needs to be increased or the drawing coefficient needs to be reduced; if the flange flatness exceeds the tolerance, the parameters of the shaping process need to be adjusted. For parts produced in batches, a process stability analysis is also required, considering the influence of factors such as material thickness deviation and mold wear, and reserving appropriate tolerance margins in the calculations. Through precise process calculations and trial punching adjustments, the forming quality of flanged cylindrical parts can be ensured and production efficiency can be improved.