Basics of Stamping Die Manufacturing

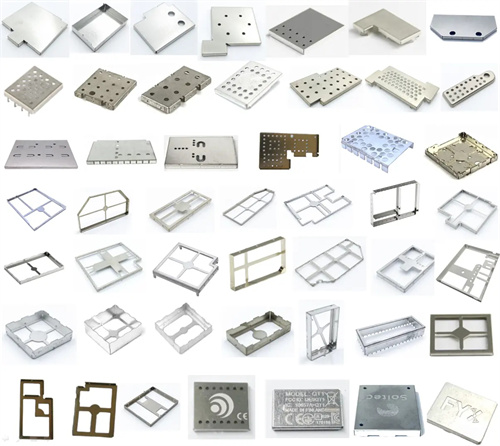

Stamping die manufacturing fundamentals are essential knowledge for die technicians. They encompass the entire die manufacturing process, from interpreting design drawings to final die inspection. Each step has its own strict technical specifications and operational requirements. Stamping die manufacturing requires not only high-precision processing equipment but also advanced manufacturing processes and a rigorous quality control system to ensure that the die meets the requirements of stamping production and produces qualified stamping parts.

The first step in stamping die manufacturing is to conduct a process analysis of the design drawings, which is a prerequisite for ensuring die manufacturing quality. The design drawings include assembly drawings and part drawings of the die. The process analysis must clarify the technical requirements of each part, such as the material, dimensional accuracy, form and position tolerances, surface roughness, etc., as well as the fit relationship and assembly accuracy between parts. At the same time, the appropriate processing methods and equipment must be selected based on the structural characteristics and production batch of the parts. For example, for punches and dies with complex shapes, EDM or wire cutting is usually used; for structural parts such as mold bases, conventional processing methods such as milling and grinding are used. The process analysis also needs to consider the positioning reference, clamping method, and measurement method during the processing to ensure the processing accuracy of the parts.

The selection of mold materials and heat treatment processes are key factors affecting mold life and performance. The working parts of stamping dies (such as the punch and die) must possess high hardness, high wear resistance, and sufficient toughness to withstand the tremendous impact and friction during the stamping process. Common mold materials include alloy tool steels such as Cr12, Cr12MoV, and CrWMn, as well as cemented carbides. These materials require forging and annealing before processing to improve their internal structure and processing properties. After processing, they also require quenching and tempering to increase their hardness and wear resistance. For example, Cr12MoV steel can achieve a hardness of HRC58-62 after quenching, offering excellent wear and impact resistance, making it suitable for manufacturing various stamping die working parts.

The machining accuracy of mold components is fundamental to ensuring mold assembly precision, necessitating the use of high-precision machining equipment and advanced processing techniques. For mold working parts, such as punches and dies, dimensional accuracy requirements typically range from IT6 to IT8, with geometric tolerances of 0.01-0.03 mm/m and surface roughness requirements of Ra0.8-0.1 μm. To achieve these requirements, high-precision machining methods such as precision grinding, EDM, and wire EDM are required. For example, wire EDM enables high-precision machining of complex parts, achieving accuracy of ±0.005 mm and surface roughness of up to Ra1.6 μm. For structural components such as mold frames, machining accuracy requirements are relatively low, but sufficient flatness, parallelism, and perpendicularity must also be maintained to ensure accurate mold guidance and assembly.

Mold assembly involves assembling machined parts into a complete mold according to design requirements. Assembly accuracy directly impacts mold performance and the quality of stamped parts. Mold assembly requires a specific assembly sequence and process to ensure precise fit and relative positioning between parts. First, the parts must be cleaned and inspected to remove impurities such as oil and iron filings from their surfaces. The dimensional accuracy and form and position tolerances must be checked to ensure they meet design requirements. Then, according to the assembly drawing, the parts are assembled one by one and secured with fasteners such as screws and pins. For key components such as the punch and die, uniform clearances must be maintained, typically achieved through shim adjustment or process locators. After assembly, a trial mold test is performed to check mold performance and the quality of the stamped parts. Any problems should be promptly adjusted and repaired.

Mold quality inspection is the last line of defense in ensuring mold manufacturing quality, requiring the use of advanced measuring instruments and scientific inspection methods. Quality inspection includes self-inspection, mutual inspection, and specialized inspection of parts, as well as final inspection after mold assembly. Part inspection primarily checks indicators such as dimensional accuracy, geometric tolerances, and surface roughness; final inspection after mold assembly primarily examines indicators such as mold assembly accuracy, guiding accuracy, gap uniformity, and the quality of stamped parts during mold trials. Commonly used measuring instruments include coordinate measuring machines (CMMs), projectors, dial indicators, and micrometers. For example, CMMs can measure the three-dimensional dimensions of complex parts with an accuracy of up to ±0.001mm, accurately reflecting the machining and assembly accuracy of the parts. Through rigorous quality inspection, problems in the mold manufacturing process can be promptly identified, allowing corrective measures to be taken to ensure mold quality.