Design of the Flanging Die for the Circular Hole of the Ventilation Seat

The design of a flanging die for circular holes in ventilation bases is a specialized technology for flanging the mounting holes of ventilation equipment bases. By axially folding the edge of the circular hole to form a cylindrical flange (3-15mm in height), this technology enhances hole strength and connection reliability. The flange achieves a verticality error of less than 0.2mm/m and maintains uniform wall thickness (thinning rate less than 10%). It is suitable for materials with thicknesses of 1-4mm, such as gray cast iron (HT250) and aluminum alloy (6061). Compared to conventional flanging dies, this die must adapt to the unusual shapes of ventilation bases (such as ribbed plates and curved surfaces). The flanging is often located on curved or inclined surfaces, requiring die design to utilize contoured positioning to ensure consistent flanging height. Initially, the prefabricated hole diameter must be calculated: d0 = d – 2h (where d is the final flanging diameter and h is the height). For example, for a hole with a flanging diameter of φ20mm and a height of 5mm, the prefabricated hole diameter is set to φ10mm.

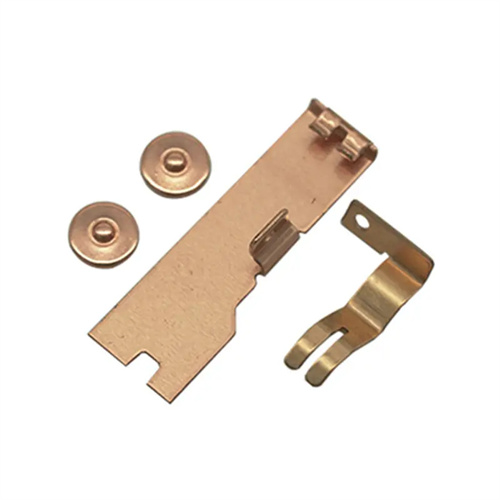

The mold structure consists of an upper die seat, a flanging punch, a flanging die, a pressure ring, a conformal positioning block and an ejection mechanism. The flanging punch is made of Cr12MoV steel, with a quenching hardness of HRC58-62. The radius of the head fillet is 1-2 times the material thickness (2mm thick, 2-4mm) to guide the material to deform evenly. The working part of the punch is coated with TiN (thickness 0.005mm) to improve wear resistance. The flanging die is designed according to the shape of the ventilation seat and adopts a split structure. The clearance between the die hole and the punch is 10%-15% of the material thickness (2mm thick, 0.2-0.3mm). The die material is Cr12, with a quenching hardness of HRC55-58, and the working surface is polished to Ra0.8μm.

Coordinated control of the pressing and flanging forces is key to the technology. The press ring is hydraulically driven, providing a pressing force of 20-50kN (30%-40% of the flanging force) to prevent material slippage during flanging. The contact surface between the press ring and the ventilated seat is machined to the part curve, achieving a fit greater than 90%. The flanging force is calculated using the formula F=π(dh)tσb (d is the flanging diameter, h is the height, t is the thickness, and σb is the tensile strength). For a 20mm φ flange made of 2mm thick 6061 aluminum alloy, the force applied is approximately 15-20kN, provided by a nitrogen spring, with a force fluctuation of ≤5%. For flanging on an inclined surface, the punch must be perpendicular to the surface, and the flanging die must be tilted accordingly, with an inclination error of less than 0.5°.

The conformal positioning system ensures precise positioning of complex curved surfaces. Multiple positioning blocks (≥3) are located at the bottom of the mold, interacting with the ribs and bosses of the ventilated seat to achieve a positioning error of ±0.1mm. The positioning blocks are made of quenched and tempered 45 steel (HRC 28-32) and are affixed with 0.5mm thick rubber pads to prevent damage to the part surface. For large ventilated seats (> 1000mm), auxiliary support mechanisms are required, with 2-3 additional support points near the flange area to minimize part deformation (deflection <0.2mm).

During debugging and quality inspection, attention is paid to the consistency of flanging. During the mold trial, the flanging height at different positions is measured (the deviation must be less than 0.3mm). When the deviation is out of tolerance, the pressing force of the corresponding area is adjusted (±2kN). If cracks appear on the flange, the radius of the punch needs to be increased or the flanging speed needs to be reduced (from 80mm/s to 60mm/s). After every 500 pieces are produced, the wear of the flanging die is checked (grinding is performed when the aperture increases by more than 0.1mm), the head of the punch is inspected with a profilometer, and it is replaced when the radius wear is more than 0.1mm. During mold maintenance, the debris in the die hole is cleaned weekly, and the oil in the hydraulic system is filtered monthly (accuracy 10μm) to ensure stable pressing force.