Design of positive and negative drawing dies for spherical shells

The design of forward and reverse drawing dies for spherical shells is a specialized forming technology developed for hemispherical or spherical shell parts (such as pressure vessel heads and ball valve housings). By preforming the spherical crown through forward drawing and then completing the entire shell through reverse drawing, high-precision forming with a wall thickness variation of less than 10% is achieved . It is suitable for materials such as mild steel and stainless steel with thicknesses of 2-8mm. During the initial design phase, the forward and reverse drawing process parameters are determined based on the shell diameter (φ200-φ1000mm). The forward drawing coefficient is 0.5-0.6, and the reverse drawing coefficient is 0.7-0.8. For example, for a φ500mm shell, forward drawing is performed to a diameter of φ650mm x a depth of 150mm, and reverse drawing is performed to a diameter of φ500mm x a depth of 250mm to ensure uniform material deformation.

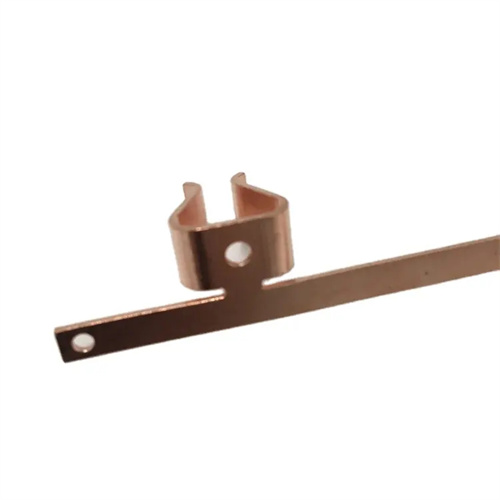

The die structure utilizes a dual-station modular layout, with the forward and reverse drawing modules coaxially arranged with a spacing of 300-500mm. The forward drawing punch is hemispherical (250mm radius), made of Cr12MoV steel, hardened to HRC 58-62, and plated with hard chrome (0.01mm thickness) to reduce the coefficient of friction to below 0.1. The reverse drawing punch, a concave spherical structure that complements the forward punch, is made of W18Cr4V high-speed steel, hardened to HRC 62-65, and features an ultra-precision ground working surface (Ra 0.1μm). Both the forward and reverse drawing dies are split-piece designs, consisting of three or four segments. Opening and closing are controlled by hydraulic cylinders, and the die corner radius is 8-10 times the material thickness (32-40mm for 4mm thick material) to guide material flow.

The core technology lies in the coordination of forward and reverse drawing forces, independently controlled by dual hydraulic systems. The forward drawing force is calculated using the formula F1=πD1tσs (D1 is the forward drawing diameter, t is the thickness, and σs is the yield strength). For a 3mm thick 20 steel spherical shell, the forward force is approximately 200-250kN. The reverse drawing force F2 is 1.2-1.5 times F1 (240-375kN). Pressure sensors monitor the force ratio in real time, ensuring a stable ratio of 1:1.2-1:1.5. A bidirectional blank holder system provides forward (30-40kN) and reverse (40-50kN) blank holder forces, respectively. Driven by nitrogen springs, the blank holder force fluctuation is ≤5%, preventing wrinkling on the shell surface.

The positioning and guiding system must ensure coaxiality during both forward and reverse drawing. A positioning mandrel is placed at the center of the mold, aligned with the pre-punched hole (φ50-φ100mm) in the shell blank, with a clearance of 0.05-0.1mm. This ensures that the center of the spherical crown coincides with the center of the reverse drawing die after forward drawing (coaxiality error <0.05mm). The guiding mechanism utilizes a four-pin layout with a diameter of 50-80mm and a clearance of 0.01-0.03mm. The pins are made of SUJ2 bearing steel, surface-hardened to HRC60-62, ensuring smooth mold movement during both forward and reverse drawing.

During debugging and quality control, attention should be paid to the accuracy of the curvature of the spherical shell. During the mold trial, laser scanning is used to detect the curvature of the inner surface of the spherical shell, and the deviation must be less than 0.5mm. The wall thickness is detected by an ultrasonic thickness gauge, and 3 points are measured in each 100mm×100mm area, and the maximum wall thickness difference is less than 0.5mm. If wrinkles appear on the crown after forward drawing, the forward blank holding force needs to be increased (by 5kN each time); if the equatorial part is too thin after reverse drawing, the reverse drawing speed needs to be reduced (from 80mm/s to 60mm/s). In daily maintenance, the oxide scale on the surface of the positive and negative punches is cleaned every 500 times of work, and the pressure value of the nitrogen spring is checked every month. If the deviation exceeds 10%, it is replaced to ensure stable force value.