Fully guided small hole punching die design

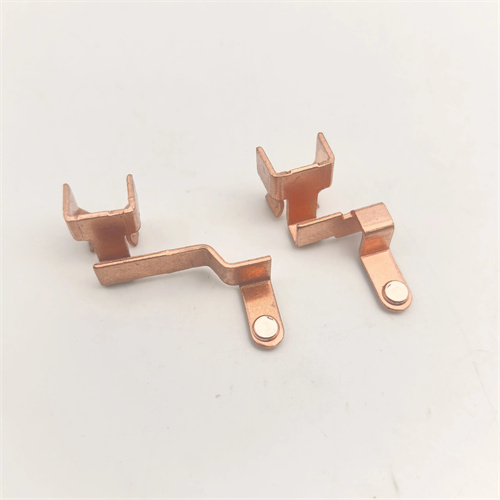

The fully guided small-hole punch design is a high-precision die technology developed for punching tiny holes (φ0.5-φ3mm). Widely used in applications such as electronic connectors and precision filter screens, it achieves hole position accuracy of ±0.01mm and a hole wall roughness of Ra0.8μm or less. It is suitable for materials with thicknesses of 0.1-1mm, such as brass and phosphor bronze. Compared to conventional small-hole punches, its core advantage lies in its through-hole guiding structure, which guides the punch from top to bottom, controlling punch deflection to within 0.005mm and preventing breakage when punching slender punches (aspect ratio > 10). The punch diameter is determined based on the hole diameter during the initial design phase. For a φ1mm hole, the punch diameter is φ0.99mm (allowing for a 0.01mm clearance), and a stepped structure (φ5mm shank diameter) is used for enhanced rigidity.

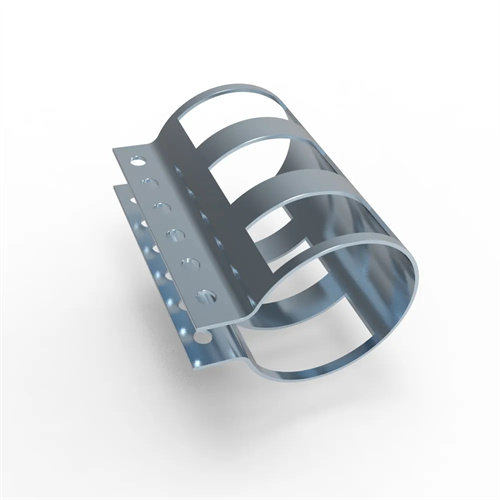

The mold structure consists of a full-length guide sleeve, a small-hole punch, a die, a precision blanking plate, and an ultra-precision guide mechanism. The small-hole punch is made of tungsten steel (WC-Co 94%) with a hardness of HRA90-92 and a surface roughness of Ra0.02μm. The working length is 8-12 times the material thickness (4-6mm for 0.5mm thick material), and the clearance between the shank and the guide sleeve is 0.001-0.003mm. The full-length guide sleeve is made of carbide (YG8), with a honed inner bore (roundness <0.001mm), creating a seamless guide with the punch. The guide sleeve is 2-3 times the length of the punch working section, ensuring zero punch runout during blanking. The die is electro-spark punched, with a cutting edge radius of <0.005mm. Made of imported carbide (V30), the thickness is 5-8 times the hole diameter (5-8mm for a φ1mm hole) to prevent deformation of the die cutting edge.

The precision holding system is key to preventing material warping. It utilizes a pneumatic diaphragm cylinder to provide a holding force of 0.5-2kN. The parallelism error between the holding plate and the die is maintained at <0.005mm/m. A clearance hole (0.1mm larger in diameter than the punch) is provided in the holding plate to ensure smooth passage of the punch. The holding force is infinitely adjustable using a precision pressure regulating valve. For 0.1mm thick brass foil, the holding force is 0.5kN; for 1mm thick phosphor bronze, the holding force increases to 1.5-2kN. A 0.05mm thick polyurethane film is applied to the holding plate to prevent surface damage.

The ultra-precision guide mechanism utilizes a combination of air hydrostatic guides and ball guides. The air hydrostatic guides provide a straightness of 0.001mm/m. During operation, compressed air at 0.4-0.6MPa is introduced, forming an air film of 5-10μm and a friction coefficient of less than 0.0001. The ball guides are φ12mm in diameter and have a clearance of 0.0005-0.001mm. Each mold is equipped with four sets of these guides, located at the four corners, ensuring synchronized movement of the upper and lower dies (phase difference less than 0.001°). Furthermore, an elastic support device is installed beneath the die, using a 0.1mm-thick beryllium bronze sheet to absorb the impact of punching and reduce the impact of vibration on hole accuracy.

Precision instruments are required for commissioning and testing. During mold trials, a scanning electron microscope (SEM) is used to observe the hole wall quality. No tears or burrs (height < 0.005mm) are allowed. A laser interferometer is used to monitor the punch trajectory, ensuring a straightness error of < 0.002mm/100mm. After every 1,000 cycles, the punch diameter is measured with a laser caliper. Replace the punch if wear exceeds 0.002mm. After every 5,000 punching cycles, the die is inspected for edge wear using a white light interferometer. Any corner radius exceeding 0.005mm is reground. Mold maintenance must be performed in a cleanroom (Class 100). During assembly, tweezers are used to hold the punch to prevent fingerprint contamination that could affect guiding accuracy.