Design of vertical two-way notching die

The vertical bidirectional notching die design is a specialized die technology for radial bidirectional notching of shaft and rod parts (such as stepped shafts and spline shafts). Widely used in mechanical transmissions, automotive transmissions, and other fields, it simultaneously punches symmetrical notches on both radial sides of the part, with a notch symmetry error of less than 0.05mm and a dimensional accuracy of ±0.1mm. This achieves a 100% improvement in efficiency compared to horizontal, single-direction punching. Its core lies in its vertical layout and bidirectional synchronous drive mechanism, which converts vertical pressure into horizontal, bidirectional punching force. It is suitable for processing cylindrical or special-shaped parts with lengths of 50-500mm and diameters of 10-100mm. Initially, the punching force must be determined based on the part diameter and notch dimensions (width 5-30mm, depth 3-15mm). The total bidirectional punching force is calculated using the formula F = 2 × L × t × σb (L is the notch circumference, t is the material thickness, and σb is the tensile strength). For a 45 steel part with a diameter of 50mm and a notch depth of 8mm, the total punching force is approximately 60-80kN.

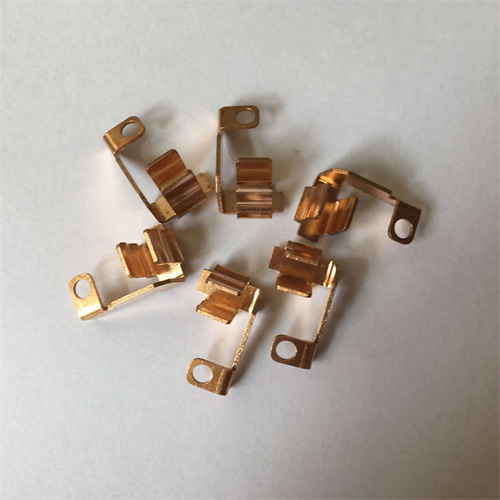

The die structure consists of an upper die drive mechanism, left and right punches, a die, a positioning mandrel, and a guide mechanism. The upper die drive utilizes a wedge-slide combination, with the wedge tilted at a 20°-30° angle. This converts the press’s vertical force into horizontal force, achieving a transmission efficiency exceeding 90%. The wedge is made of Cr12MoV, hardened to HRC 58-62, and the clearance between the slide and guide rail is 0.01-0.03mm, ensuring smooth movement. The left and right punches are symmetrically arranged and designed according to the notch shape (typically rectangular or semicircular). They are made of W6Mo5Cr4V2 high-speed steel, hardened to HRC 62-65, with an edge sharpness of Ra 0.8μm or less. The punch and slide are connected by a dovetail groove, and replacement time is less than 10 minutes. The die adopts a split structure, consisting of a left die and a right die. A positioning pin is set on the joint surface to ensure that the coaxiality of the die hole is less than 0.02mm. The material is Cr12 steel with a quenching hardness of HRC55-58. The fitting clearance between the die hole and the part is 0.05-0.1mm, which is convenient for loading and unloading of parts.

A synchronous drive system ensures consistent bidirectional punching. A synchronous gear or connecting rod mechanism is installed between the left and right sliders. The gear drive tooth side clearance is less than 0.01mm, and the connecting rod mechanism hinge clearance is less than 0.02mm, ensuring that the speed difference between the two punches is less than 0.05mm/s. For high-precision requirements, a servo motor can be used to drive the ball screw. The control system achieves closed-loop position control of the punches on both sides, with a synchronization error of less than 0.01mm. The punch stroke is precisely controlled by a limit block, with a stroke error of ±0.05mm, ensuring consistent notch depth.

Positioning and clamping devices must be adapted to the characteristics of shaft parts. Positioning utilizes a combination of V-blocks and end plates, with a 90°-120° angle. The V-blocks are made of HT300 cast iron, surface-hardened to HRC40-45, and are complemented by polyurethane pads to prevent surface scratches. The clamping device utilizes pneumatic chucks or hydraulic jaws with a clamping force of 5-20kN, adjusted according to part diameter, to ensure no rotation or axial movement during blanking. For slender shafts with an aspect ratio greater than 5, intermediate supports are required, spaced 100-200mm apart to prevent bending and deformation.

During commissioning and maintenance, emphasis is placed on managing synchronization accuracy. During die trials, a laser interferometer is used to measure the displacement difference between the two punches. If the synchronization error exceeds 0.03mm, the gear clearance or connecting rod length must be adjusted (±0.01mm). A three-dimensional coordinate measuring machine is used to check the symmetry and dimensions of the notches. Five pieces are sampled per batch, and if deviations are found, the die position or punch dimensions are adjusted. During routine maintenance, the contact surface between the wedge and the slide is lubricated with high-temperature grease (resistant to temperatures exceeding 150°C) every 1,000 cycles. The gear transmission system is inspected weekly and filled with extreme-pressure gear oil. The clamping jaws are ground every 5,000 cycles to ensure positioning accuracy. When storing the die, the punch must be returned to its starting position, and anti-rust oil must be applied to the cutting edge to prevent rust.