Design of compound die for blanking, bending and flanging

The design of a composite die for blanking, bending, and flanging integrates blanking, multi-angle bending, and hole flanging. Suitable for parts with complex hemming and hole flanging features (such as automotive door latches and appliance mounting brackets), it completes all steps from flat sheet to finished product in a single press. Part verticality tolerance is less than 0.1mm/m, and the flanging height tolerance is ±0.05mm. This improves production efficiency by over 40% compared to single-step dies. During the initial design phase, process simulation is used to determine the process sequence, adhering to the “blank-bending-flanging” principle. For example, an L-shaped part with a hole and flanging requires first blanking to obtain the outline, then performing a 90° bend, and finally flanging the φ8mm prefabricated hole (3mm height) to prevent material flow during flanging from interfering with the bending angle.

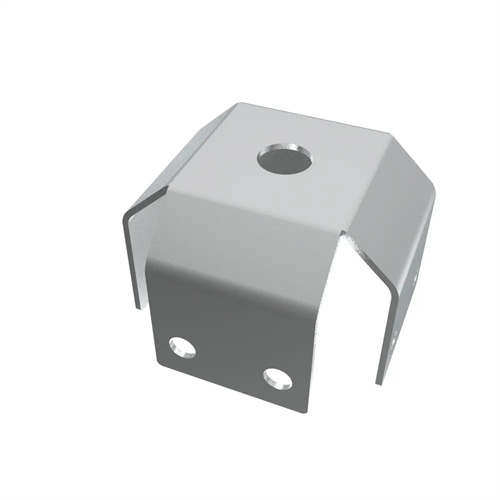

The die structure consists of a multifunctional punch assembly, a composite die, a positioning system, and an elastic clamping mechanism. The blanking cutting edge adopts an integrated design. The Cr12MoV steel punch and die are hardened to HRC 58-62, with a cutting edge clearance set at 8%-10% of the material thickness (0.12-0.15mm for 1.5mm thick material). The working portion of the bending punch is constructed of W6Mo5Cr4V2 high-speed steel, hardened to HRC 62-65. The bending radius is 1.5-2 times the material thickness (2.25-3mm for 1.5mm thick material), with a 0.5° springback compensation angle. The flanging punch head features a spherical transition (2mm radius), and the clearance between the punch and die is 1.1 times the material thickness (1.65mm) to ensure wrinkle-free flanging.

The coordinated control of the pressing and forming forces is crucial to quality. A three-stage pressure regulation system is employed: during the blanking phase, a spring provides a preload of 5-8kN to secure the blank; during the bending phase, a nitrogen spring outputs a bending force of 15-20kN to ensure a stable bending angle; during the flanging phase, the pressure is increased to 20-25kN to suppress radial shrinkage of the material during flanging. The guide clearance between the pressing plate and the punch is controlled at 0.03-0.05mm, ensuring flexible movement while limiting material deflection. For multi-angle curved parts, a synchronized bending mechanism is employed, using a rack-and-pinion transmission to ensure a time difference of less than 0.02 seconds between the bending arms to prevent part distortion.

The positioning system utilizes a combination of “hole positioning + contour guidance.” After blanking, two φ6mm locating pins mate with the die holes (with a clearance of 0.01-0.02mm). Before bending, lateral guides limit lateral displacement (with a clearance of 0.1mm). Auxiliary locating blocks are added to the flanging station to align with the pre-formed curved surface of the part, keeping positioning errors within 0.03mm. For parts without preformed holes, process locating holes (φ3-5mm) are punched during the blanking process. Pilot pins are used in subsequent steps for precise positioning, ensuring a ±0.1mm tolerance between the flanging hole and the edge.

Digital management is implemented for commissioning and quality control. During mold trials, the forming process is recorded with high-speed video. Comparisons with CAE simulation results are used to optimize the cutting depth of the bending punch (adjustment within ±0.1mm). Laser scanning is used to check the verticality of the holes after flanging (tolerance required to be <0.05mm). If flaring occurs, the radius of the flanging punch head is reduced by 0.2mm at a time. During routine maintenance, the bending punch is calibrated every 2,000 units (tolerance <0.1°). The wear block (YG15 carbide) of the flanging die is inspected every 5,000 units and replaced if wear exceeds 0.02mm to ensure stable flanging dimensions.