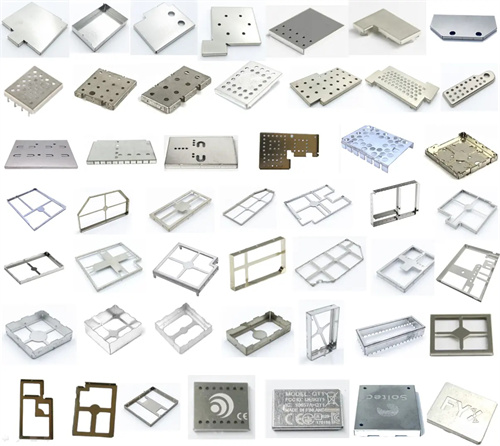

In the vibrant and imaginative world of the toy industry, stamped metal parts have emerged as essential elements that significantly enhance the durability, functionality, and safety of toys. These precisely crafted components, formed through the stamping of metal sheets, combine the strength, resilience, and aesthetic appeal of metals with the creativity and innovation of toy design. From providing sturdy structures for construction toys to enabling interactive features in electronic toys, stamped metal parts play a crucial role in our mission to create toys that not only entertain but also withstand the rigors of playful exploration. They have seamlessly integrated into our manufacturing processes, allowing us to produce toys that meet the highest standards of quality and safety for children around the world.

1. Stamped Metal Parts: Building Robust Structures in Construction Toys

One of the primary applications of stamped metal parts in the toy industry is in construction toys, where they serve as the backbone for creating sturdy and long – lasting structures. We utilize stamped metal connectors, brackets, and frames to build toy sets that encourage children’s creativity and spatial awareness. In metal building block sets, stamped metal connectors are the key components that hold the blocks together. These connectors, stamped with precise holes and slots, ensure a secure and tight fit, allowing children to construct complex structures without the pieces easily falling apart.

For example, in large – scale construction toy sets designed for building skyscrapers or bridges, stamped steel frames provide the necessary strength to support the weight of multiple blocks. The high – strength properties of the stamped metal parts ensure that the structures can withstand the rough handling typical of children’s play. Moreover, the corrosion – resistant nature of metals like stainless steel or coated steel used in stamping protects these parts from wear and tear caused by moisture or accidental spills, extending the lifespan of the toys and providing a more reliable play experience.

2. Stamped Metal Parts: Ensuring Safety and Durability in Ride – on Toys

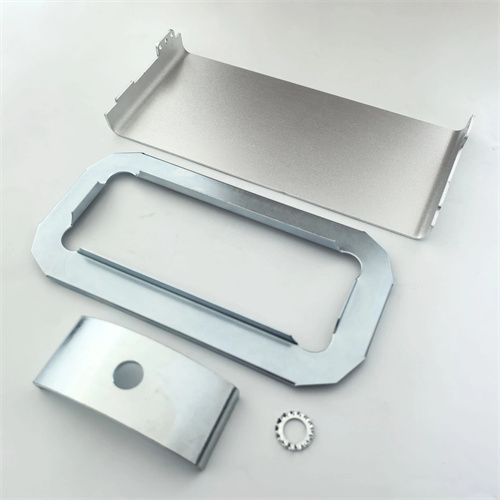

Safety and durability are of utmost importance in ride – on toys, and stamped metal parts play a vital role in meeting these requirements. We use stamped metal frames and axles in toys such as tricycles, scooters, and pedal cars to provide a stable and secure base for children. The stamped metal frames, often made from steel or aluminum, are designed to bear the weight of the child and withstand the impact of various terrains.

For instance, in children’s tricycles, stamped metal axles ensure smooth rotation of the wheels, while the stamped metal frame provides the necessary rigidity to prevent the toy from wobbling or collapsing. The precision stamping process allows for the creation of parts with exact dimensions, ensuring a perfect fit for all components and enhancing the overall safety of the ride – on toy. Additionally, the use of stamped metal parts with rounded edges and smooth surfaces eliminates the risk of sharp corners that could potentially harm children during play.

3. Stamped Metal Parts: Enabling Interactive Features in Electronic Toys

Stamped metal parts also play a crucial role in enabling interactive features in electronic toys. In toys with lights, sounds, and movement functions, we rely on stamped metal contacts, connectors, and springs to ensure reliable electrical connections and smooth operation. For example, in a battery – operated toy robot that can move, speak, and light up, stamped metal contacts are used to connect the battery to the electronic circuit board. These contacts are designed with a secure locking mechanism to prevent loose connections, which could disrupt the toy’s functions.

Stamped metal springs are often used in electronic toys to create interactive mechanisms, such as buttons that trigger different actions. The elasticity and durability of the stamped metal springs allow for repeated use without losing their shape or functionality. Moreover, stamped metal connectors are used to link various components within the toy, ensuring the seamless transmission of electrical signals and power, and enhancing the overall performance and playability of the electronic toy.

4. Stamped Metal Parts: Enhancing Aesthetic Appeal in Toy Design

Aesthetic appeal is an important aspect of toy design, and stamped metal parts can significantly enhance the visual attractiveness of toys. We use stamped metal decorative elements, such as logos, emblems, and trims, to add a touch of elegance and style to toys. In action figures, stamped metal badges or insignias can be attached to the costumes to give them a more realistic and detailed appearance.

For example, in a superhero – themed action figure set, the stamped metal logos on the capes and chests of the figures not only look visually appealing but also add a sense of authenticity to the characters. In toy vehicles, stamped metal grilles, wheels, and exhaust pipes can be used to create a more realistic and stylish look. The precision of the stamping process allows for the creation of intricate designs and patterns, making the toys more eye – catching and appealing to children. Additionally, the shiny surface of stamped metal parts can be further polished or coated to create different visual effects, enhancing the overall aesthetic of the toys.

5. Stamped Metal Parts: Driving Innovation in Toy Manufacturing

As the toy industry continues to evolve, stamped metal parts are at the forefront of driving innovation in toy manufacturing. Advanced stamping technologies, combined with the versatility of metal materials, enable us to create parts with complex geometries and novel features. We can stamp metal into unique shapes and sizes to meet the specific requirements of new toy designs, such as creating custom – made metal parts for limited – edition or collectible toys.

The recyclability of metal materials used in stamped parts also promotes sustainable toy manufacturing practices. By incorporating stamped metal parts, we can reduce the environmental impact of toy production and disposal. Moreover, new surface treatment and coating technologies for stamped metal parts, such as powder coating or electroplating, can be applied to improve their performance, durability, and aesthetic appearance. Through continuous exploration and application of stamped metal parts, we can drive the development of more innovative, high – quality, and environmentally friendly toys that inspire the imagination of children and meet the changing demands of the market.