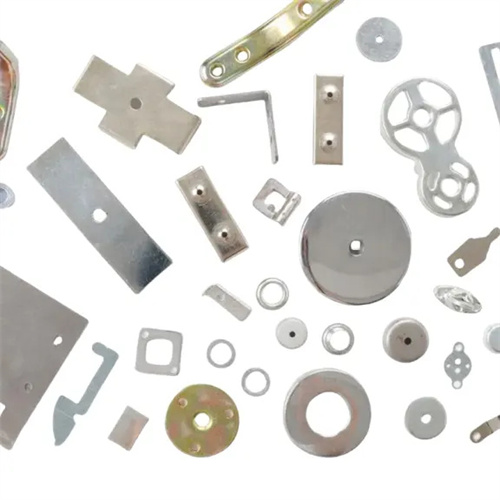

In the vibrant and imaginative toy industry, spring steel stamped parts have emerged as essential elements that add functionality, durability, and play value to a wide range of toys. These parts, meticulously crafted by stamping spring steel sheets under high pressure, combine the excellent elastic properties and strength of spring steel with the precision of modern manufacturing. From enabling interactive features in electronic toys to providing structural support in construction toys, spring steel stamped parts play a crucial role in our pursuit of creating engaging, safe, and long – lasting toys. They have seamlessly integrated into our toy – making processes, allowing us to bring joy and inspiration to children through innovative and high – quality products.

1. Spring Steel Stamped Parts: Enabling Interactive Features in Electronic Toys

One of the primary applications of spring steel stamped parts in the toy industry is in electronic toys, where they enable interactive and engaging features. We incorporate spring steel – stamped contacts and connectors into toys with lights, sounds, and motion functions. In battery – operated toy cars, for example, spring steel – stamped terminal connectors ensure a stable electrical connection between the battery and the motor. The spring – loaded design of these connectors applies consistent pressure, preventing loose connections that could disrupt the toy’s operation. This reliability allows children to enjoy uninterrupted playtime as the cars speed across the floor.

In musical toys, spring steel – stamped metal reeds are used to produce sound. These reeds, stamped with precise dimensions, vibrate when air passes over them, creating clear and pleasant tones. The stamping process ensures that each reed has the right thickness and shape, resulting in consistent sound quality. For instance, in a toy harmonica, the spring steel – stamped reeds are carefully tuned to produce different musical notes, allowing children to experiment with creating melodies and develop an interest in music.

2. Spring Steel Stamped Parts: Providing Structural Support in Construction Toys

Construction toys rely on spring steel stamped parts to provide the necessary structural support and stability. In metal building block sets, spring steel – stamped connectors and brackets are the key components that hold the blocks together. These connectors are designed with a spring – like mechanism that allows them to snap firmly onto the blocks, creating sturdy structures. The elasticity of the spring steel ensures that the connections are strong enough to withstand rough play, yet flexible enough to be easily assembled and disassembled by children.

For example, in a large – scale metal construction toy set, spring steel – stamped L – shaped and T – shaped connectors enable children to build complex structures like towers, bridges, and castles. The precision of the stamping process guarantees that each connector fits perfectly with the blocks, enhancing the overall building experience. Additionally, spring steel – stamped frames can be used in wooden or plastic construction toys to reinforce weak points, adding durability and extending the lifespan of the toys.

3. Spring Steel Stamped Parts: Enhancing Movement in Action Figures and Dolls

Spring steel stamped parts play a vital role in enhancing the movement and poseability of action figures and dolls. We use spring steel – stamped joints to create flexible and realistic articulation. In action figures, ball – and – socket joints made from spring steel allow for a wide range of motion, enabling children to pose the figures in various dynamic positions, such as running, jumping, or fighting stances. The springy nature of the steel in these joints provides resistance, helping the figures maintain their poses without flopping over.

In dolls, spring steel – stamped mechanisms can be used for features like opening and closing eyes or moving limbs. For example, a doll with spring steel – stamped eyelid mechanisms can blink realistically, adding a touch of charm and interactivity. The stamping process allows for the creation of these delicate components with high precision, ensuring smooth and reliable operation over time. These spring steel stamped parts not only make the toys more fun to play with but also encourage children’s creativity and storytelling.

4. Spring Steel Stamped Parts: Ensuring Safety in Toy Design

Safety is of utmost importance in the toy industry, and spring steel stamped parts are designed with strict safety standards in mind. We ensure that all spring steel – stamped parts used in toys are free from sharp edges and burrs, which could potentially harm children. The stamping process is carefully controlled to produce parts with smooth surfaces and rounded edges. In addition, the strength and durability of spring steel ensure that the parts do not break or deform easily during normal play, reducing the risk of small parts detachment that could pose a choking hazard.

For example, in toys with spring – loaded mechanisms, such as pop – up toys or toys with features, spring steel – stamped components are engineered to withstand the forces involved without failing. The spring steel is heat – treated and tested to ensure it maintains its properties over time, providing a safe and reliable play experience for children. By using spring steel stamped parts that meet rigorous safety requirements, we can give parents peace of mind knowing that the toys their children play with are secure.

5. Spring Steel Stamped Parts: Driving Innovation in Toy Design

As the toy industry continues to evolve, spring steel stamped parts are at the forefront of driving innovation in toy design. Advanced stamping technologies, combined with the unique properties of spring steel, enable us to create parts with increasingly complex geometries and novel features. For example, we can stamp spring steel into intricate shapes to create toys with interactive elements that respond to touch or movement. In a new generation of smart toys, spring steel – stamped sensors and actuators can be integrated to create more intelligent and responsive play experiences.

The use of spring steel also allows for the development of more sustainable toy designs. By creating parts that are easy to repair or recycle, we can reduce the environmental impact of toy production. Additionally, new surface treatment and coating technologies for spring steel stamped parts can improve their aesthetic appeal, making the toys more visually attractive. Through continuous exploration and application of spring steel stamped parts, we can bring forth innovative toys that capture the imagination of children and keep up with the changing trends in the toy industry.