In the ever – evolving packaging industry, stamped metal parts have emerged as essential components that offer a perfect blend of strength, durability, and functionality. These parts, crafted through the precise stamping of metal sheets, play a crucial role in various packaging applications, from safeguarding products during transit to enhancing the aesthetic appeal of packages. By leveraging different metal materials such as steel, aluminum, and tin, we can tailor stamped metal parts to meet the diverse needs of the packaging sector. They have seamlessly integrated into our packaging processes, enabling us to create reliable, efficient, and visually appealing packaging solutions.

1. Stamped Metal Parts: Reinforcing Packaging Structures

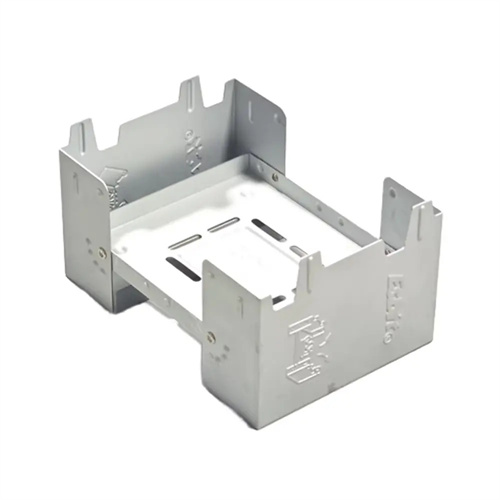

One of the primary applications of stamped metal parts in the packaging industry is to reinforce the structures of various packages. We utilize stamped metal frames, brackets, and corner protectors to enhance the strength and stability of cardboard, paperboard, and even some plastic packaging. In large – format cardboard boxes used for shipping heavy items like furniture or electronics, stamped steel corner protectors are often applied. These protectors, with their precisely stamped L – shaped design, are attached to the corners of the boxes, providing additional support and preventing damage from impacts during handling and transportation.

For metal packaging such as drums and cans, stamped metal bands and rings are crucial for reinforcing seams and joints. These parts, stamped from sturdy metal sheets, ensure that the containers can withstand the pressure and stress during filling, storage, and transit. The high strength of stamped metal parts guarantees that the packaging structures remain intact, protecting the contents inside and reducing the risk of leakage or breakage.

2. Stamped Metal Parts: Ensuring Secure Packaging Closures

Secure closures are vital for maintaining the integrity of packaged products, and stamped metal parts play a significant role in this aspect. We rely on stamped metal clips, latches, and hinges to create reliable sealing mechanisms for various types of packaging. In food and beverage cans, stamped metal clips are used to fasten the lids, ensuring a tight seal that prevents contamination and preserves the freshness of the contents. These clips are stamped with precise shapes and dimensions to fit the can lids perfectly, providing a secure and tamper – evident closure.

In packaging boxes and containers, stamped metal hinges are commonly used to enable smooth opening and closing. These hinges, stamped from durable metal materials, can endure repeated use without loosening or breaking. Additionally, stamped metal latches with spring – loaded mechanisms are employed to keep the boxes securely closed, preventing accidental opening during transportation and storage.

3. Stamped Metal Parts: Facilitating Hygienic Packaging Solutions

In industries where hygiene is of utmost importance, such as the food and pharmaceutical sectors, stamped metal parts are ideal for facilitating hygienic packaging solutions. We use stamped metal components in packaging equipment and containers due to their non – porous surfaces and resistance to corrosion, which make them easy to clean and sterilize. Stamped stainless steel trays and holders, for example, are widely used in pharmaceutical packaging to store and transport tablets and capsules. The smooth surface of these trays prevents the accumulation of residues, ensuring a clean and sterile environment for the products.

In food processing plants, stamped metal conveyor belts and guides are essential components in packaging lines. These parts, made from corrosion – resistant metals, can withstand the harsh cleaning agents and frequent washdowns required to maintain hygiene standards. The use of stamped metal parts in these applications helps us meet strict regulatory requirements and ensures the safety and quality of packaged products.

4. Stamped Metal Parts: Enhancing the Aesthetic Appeal of Packaging

Aesthetic appeal can significantly influence consumer perception, and stamped metal parts contribute to enhancing the visual attractiveness of packaging. We use stamped metal decorative elements, such as logos, emblems, and trims, to add a touch of elegance and sophistication to packages. In luxury product packaging, stamped metal plates with embossed logos are often attached to boxes or bags, creating a premium and exclusive look. The precision stamping process allows for the creation of detailed and intricate designs, enhancing the brand image and making the packaging more appealing to consumers.

For decorative packaging items like gift boxes and tins, stamped metal patterns and textures can be used to create unique and eye – catching designs. These aesthetic enhancements not only make the packaging more visually appealing but also add value to the products inside, making them more attractive to potential buyers.

5. Stamped Metal Parts: Driving Innovation in Packaging Design

As the packaging industry continues to innovate, stamped metal parts are at the forefront of driving design advancements. Advanced stamping technologies, combined with the versatility of metal materials, enable us to create parts with complex geometries and novel features. We can stamp metal into custom shapes and sizes to meet the specific requirements of different packaging designs, such as creating unique closures for specialized containers or designing intricate metal inserts for product protection.

The recyclability of metal materials used in stamped parts also promotes sustainable packaging design. By incorporating stamped metal parts, we can reduce the environmental impact of packaging production and disposal. Additionally, new surface treatment and coating technologies for stamped metal parts, such as powder coating and electroplating, can be applied to improve their performance, durability, and aesthetic appearance. Through continuous exploration and application of stamped metal parts, we can drive the development of more innovative, sustainable, and functional packaging solutions in the industry.