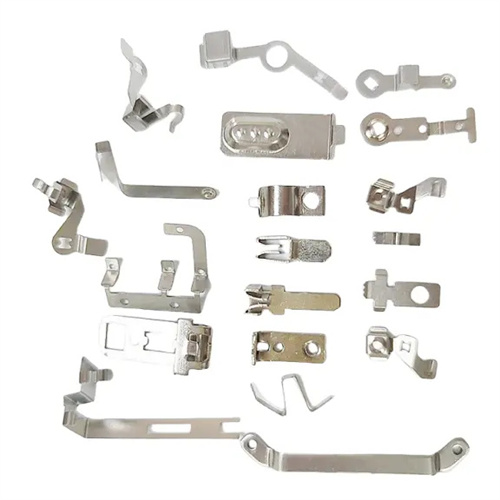

In the dynamic and innovative field of LED lighting, spring steel stamped parts have emerged as essential components that significantly contribute to the performance, reliability, and functionality of various lighting products. These parts, crafted by precisely stamping spring steel sheets under high pressure, combine the excellent elasticity and strength of spring steel with the precision of stamping technology. From ensuring stable electrical connections to enhancing the structural integrity of lighting fixtures, spring steel stamped parts play a crucial role in our pursuit of creating high – quality, energy – efficient LED lighting solutions. They have become an integral part of our manufacturing process, enabling us to produce LED lighting products that meet the diverse needs of different applications.

1. Spring Steel Stamped Parts: Ensuring Secure Electrical Connections in LED Lighting

One of the primary applications of spring steel stamped parts in LED lighting is in establishing secure electrical connections. We rely on spring steel – stamped connectors, terminals, and contacts to facilitate the transmission of electrical signals and power within LED devices. In LED modules, spring steel – stamped terminal blocks are commonly used to connect the LED chips to the power supply. These terminal blocks are designed with spring – loaded contacts, which are stamped from spring steel to ensure a constant and reliable pressure on the wires. This pressure guarantees a low – resistance electrical connection, minimizing the risk of power loss and overheating.

For example, in outdoor LED streetlights, spring steel – stamped connectors are used to link the LED light strings. The springy nature of these connectors allows them to adapt to temperature changes and vibrations, maintaining a stable connection even in harsh environmental conditions. The stamping process enables the creation of connectors with precise geometries, ensuring a perfect fit for different wire gauges and facilitating easy installation and maintenance. By using spring steel stamped parts for electrical connections, we can enhance the reliability and longevity of LED lighting systems.

2. Spring Steel Stamped Parts: Enhancing Heat Dissipation in LED Lighting

Heat dissipation is a critical factor in the performance and lifespan of LED lighting, and spring steel stamped parts can play a supporting role in this aspect. In some LED lighting designs, spring steel – stamped brackets are used to mount heat sinks. These brackets are stamped with precise shapes and dimensions to securely hold the heat sinks in place while allowing for proper air circulation around them. The elasticity of spring steel ensures that the brackets can accommodate slight thermal expansions and contractions of the heat sinks without loosening.

For instance, in high – power LED floodlights, spring steel – stamped clips are used to attach fin – type heat sinks to the LED modules. The clips, with their springy characteristics, provide a firm grip on the heat sinks, ensuring efficient heat transfer from the LED chips to the heat – dissipating surfaces. Additionally, spring steel – stamped heat – conducting pads can be used to enhance the thermal contact between the LED chips and the heat sinks. These pads, stamped from thin spring steel sheets with a high – thermal – conductivity coating, conform to the surfaces of the components, reducing thermal resistance and improving the overall heat – dissipation efficiency of the LED lighting products.

3. Spring Steel Stamped Parts: Optimizing Optical Performance in LED Lighting

Spring steel stamped parts also contribute to optimizing the optical performance of LED lighting. In LED luminaires, spring steel – stamped reflectors can be used to direct the light emitted by the LEDs. These reflectors are stamped from highly reflective spring steel sheets and shaped into precise parabolic or elliptical forms. The springy property of the steel allows for some flexibility during the installation process, ensuring a better fit with the LED light sources and minimizing light leakage.

For example, in indoor LED downlights, spring steel – stamped reflectors are designed to focus the light downwards, increasing the illuminance on the target area. The reflective surfaces of the stamped parts are carefully polished and coated to maximize light reflection, improving the overall luminous efficiency of the luminaires. Moreover, spring steel – stamped diffuser frames can be used to hold diffuser panels in place. These frames, with their spring – loaded clips, ensure a secure and even mounting of the diffusers, helping to create a more uniform and comfortable lighting effect by softening the light and reducing glare.

4. Spring Steel Stamped Parts: Providing Structural Support in LED Lighting Fixtures

In LED lighting fixtures, spring steel stamped parts offer essential structural support and enhance the overall durability of the products. Spring steel – stamped frames and brackets are used to assemble different components of the fixtures, such as the LED modules, drivers, and covers. These parts are stamped with precise holes, slots, and tabs, ensuring a perfect fit and easy assembly.

For example, in LED panel lights, spring steel – stamped metal frames provide the necessary rigidity to maintain the flat shape of the panel and support the weight of the internal components. The springy nature of the steel allows the frames to absorb minor impacts and vibrations, protecting the delicate LED chips and other electronic parts inside. Additionally, spring steel – stamped mounting brackets are used to attach the lighting fixtures to ceilings, walls, or other surfaces. These brackets, with their adjustable spring – loaded mechanisms, can be easily installed and adjusted to fit different installation requirements, providing a stable and reliable mounting solution for LED lighting products.

5. Spring Steel Stamped Parts: Driving Innovation in LED Lighting Design

As the LED lighting industry continues to evolve, spring steel stamped parts are at the forefront of driving innovation in product design. Advanced stamping technologies, combined with the unique properties of spring steel, enable us to create parts with complex geometries and innovative features. For example, we can stamp spring steel into intricate shapes to create flexible LED light – guide structures, which can be used to design unique lighting effects and shapes.

The use of spring steel in stamped parts also allows for the development of self – adjusting and self – centering components in LED lighting. In some new – generation LED bulbs, spring steel – stamped contacts are designed to automatically adjust to different socket types, ensuring a secure connection without the need for manual adjustment. Moreover, by exploring new surface treatment and coating technologies for spring steel stamped parts, we can improve their corrosion resistance, aesthetic appearance, and functionality, opening up new possibilities for creating more energy – efficient, intelligent, and stylish LED lighting products that meet the evolving needs of consumers.