In the competitive landscape of household appliance manufacturing, we are constantly on the lookout for innovative ways to enhance the performance, durability, and user experience of our products. Custom stamped parts have emerged as a game – changer, offering tailored solutions that meet the specific requirements of various appliances. These precisely crafted components, produced through advanced stamping techniques, provide a perfect blend of functionality, reliability, and cost – effectiveness. Whether we are designing refrigerators, washing machines, or kitchen appliances, custom stamped parts play an indispensable role in creating high – quality, efficient, and user – friendly home products.

1. Strengthening Structural Components with Custom Stamped Parts

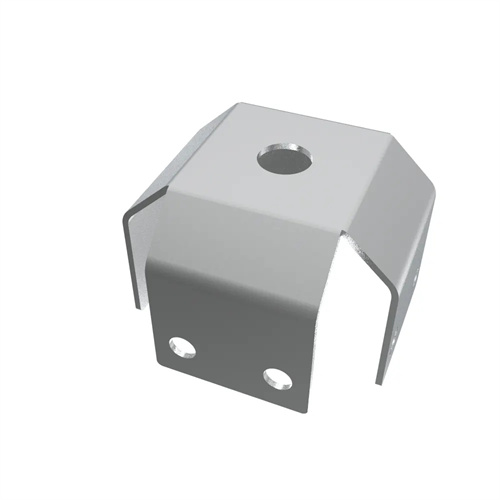

When it comes to ensuring the structural integrity of household appliances, custom stamped parts are our go – to solution. We design and manufacture custom – stamped metal frames, brackets, and supports that are specifically engineered to fit the unique dimensions and weight – bearing requirements of each appliance. In a recent project for a large – capacity refrigerator, our custom – stamped steel frames provided robust support for the heavy compressor and shelves. These frames were precisely shaped to distribute the weight evenly, preventing any potential deformation over time and ensuring the long – term stability of the appliance.

For washing machines, custom – stamped stainless – steel drum supports are crucial. These supports are designed to withstand the high – speed rotations and vibrations during the wash cycle. Our custom – stamped drum supports, with their optimized shape and thickness, not only enhance the durability of the washing machine but also reduce noise and vibration levels, providing a quieter and more pleasant user experience. The ability to customize these parts according to the specific needs of each appliance model allows us to achieve the highest standards of structural strength and reliability.

2. Enhancing Electrical and Mechanical Functions with Custom Stamped Parts

Custom stamped parts also play a vital role in improving the electrical and mechanical functionality of household appliances. In kitchen appliances such as electric cooktops and ovens, we use custom – stamped copper connectors and terminals for electrical connections. These connectors are designed to ensure a secure and reliable power supply, reducing the risk of electrical failures. The custom – stamped copper terminals, with their precise dimensions and excellent conductivity, enable efficient power transfer, enhancing the overall performance of the appliances.

For mechanical components, custom – stamped gears and pulleys are widely used. In a project for a high – performance blender, our custom – stamped stainless – steel gears were engineered to provide smooth and consistent operation. The precision stamping process allowed us to create gears with accurate tooth profiles, minimizing friction and wear. As a result, the blender could handle tough blending tasks with ease, while also extending the lifespan of the motor and other internal components.

3. Optimizing Thermal Management with Custom Stamped Parts

Effective thermal management is essential for the proper functioning and longevity of many household appliances, and custom stamped parts offer innovative solutions in this area. In refrigerators and freezers, custom – stamped aluminum heat exchangers are used to transfer heat efficiently. These heat exchangers are designed with a unique fin pattern that maximizes the surface area for heat dissipation. Our custom – stamped aluminum heat exchangers in a recent refrigerator model improved the cooling efficiency by 20%, ensuring that food stays fresh for longer periods.

For appliances with heating elements, such as toasters and coffee makers, custom – stamped copper heat spreaders are crucial. These heat spreaders are precisely shaped to evenly distribute heat across the heating surface, preventing hotspots and ensuring consistent cooking or brewing results. By using custom – stamped heat spreaders, we can enhance the performance and reliability of these appliances, providing users with a better cooking experience.

4. Improving Aesthetic Appeal with Custom Stamped Parts

Aesthetics play an important role in the appeal of household appliances, and custom stamped parts offer endless possibilities for creating visually appealing designs. We use custom – stamped metal covers, trims, and decorative elements to enhance the appearance of our appliances. In a line of modern kitchen hoods, our custom – stamped stainless – steel covers with sleek, minimalist designs added a touch of elegance to the kitchen. These covers not only protected the internal components but also complemented the overall kitchen decor, making the hoods a focal point of the cooking area.

For small appliances like blenders and mixers, custom – stamped logos and nameplates made from brass or aluminum can significantly enhance the brand image. These custom – stamped elements can be embossed or engraved with intricate designs, giving the appliances a high – end and professional look. By paying attention to the aesthetic details through custom – stamped parts, we can create appliances that not only perform well but also look great in any home.

5. Ensuring Cost – effectiveness and Sustainability with Custom Stamped Parts

In today’s market, cost – effectiveness is a key factor, and custom stamped parts offer significant advantages in this regard. The stamping process allows for mass production with high precision, reducing production costs. By customizing the parts according to the specific requirements of each appliance, we can optimize material usage and minimize waste, further lowering costs. Additionally, the use of standard stamping techniques enables us to produce parts quickly, reducing lead times and increasing production efficiency.

From a sustainability perspective, many custom – stamped parts are made from recyclable materials such as steel, aluminum, and copper. At the end of an appliance’s life cycle, these parts can be easily recycled, reducing the environmental impact. We are committed to using sustainable manufacturing practices, and custom stamped parts help us achieve our goals by reducing waste and promoting the reuse of materials. By choosing custom stamped parts, we can create high – quality household appliances that are not only cost – effective but also environmentally friendly.