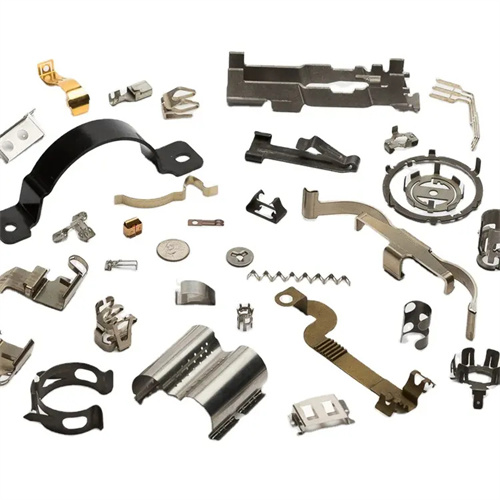

In the fast – paced and highly competitive world of electronic products, stainless steel stamped parts have emerged as indispensable components that significantly enhance the performance, durability, and aesthetic appeal of various devices. These precisely crafted parts, formed by stamping stainless steel sheets under high pressure, combine the excellent properties of stainless steel, such as corrosion resistance, strength, and malleability, with the precision of modern manufacturing techniques. From providing structural support to ensuring reliable electrical connections, stainless steel stamped parts play a crucial role in our pursuit of creating cutting – edge, high – quality electronic products. They have seamlessly integrated into our production processes, enabling us to deliver electronics that meet the diverse and evolving needs of consumers.

1. Stainless Steel Stamped Parts: Offering Robust Structural Support

One of the primary applications of stainless steel stamped parts in electronic products is to offer robust structural support. We utilize stainless steel – stamped frames, brackets, and casings to ensure the integrity and stability of devices. In smartphones and tablets, stainless steel – stamped frames serve as the backbone, providing a lightweight yet sturdy structure. The high strength of stainless steel allows these frames to withstand daily wear and tear, accidental drops, and impacts, protecting the delicate internal components such as the circuit boards, batteries, and displays.

For example, in high – end smartphones, stainless steel – stamped mid – frames not only enhance the device’s durability but also contribute to its sleek and premium look. The precision stamping process enables the creation of frames with precise cutouts for buttons, ports, and antennas, ensuring a perfect fit for all components. In laptops, stainless steel – stamped hinges and brackets are used to support the screen and allow for smooth opening and closing. These parts can endure thousands of opening and closing cycles without loosening or breaking, ensuring the long – term usability of the laptops.

2. Stainless Steel Stamped Parts: Ensuring Reliable Electrical Connections

Stainless steel stamped parts also play a vital role in ensuring reliable electrical connections within electronic products. We rely on stainless steel – stamped connectors, terminals, and contacts to facilitate the transmission of electrical signals and power. In printed circuit boards (PCBs), stainless steel – stamped terminal blocks are used to connect wires and components securely. The corrosion – resistant property of stainless steel ensures that these terminal blocks remain functional over time, even in environments with high humidity or exposure to dust.

For instance, in automotive electronics, where the components are exposed to vibrations, temperature fluctuations, and moisture, stainless steel – stamped connectors are used to link various electrical systems. These connectors are designed with precise geometries and locking mechanisms to prevent loose connections, which could lead to electrical failures. In data centers, stainless steel – stamped electrical contacts are used in servers and storage devices. Their excellent conductivity and durability ensure stable data transmission and power supply, minimizing the risk of system downtime.

3. Stainless Steel Stamped Parts: Enhancing Thermal Management

Thermal management is crucial for the performance and lifespan of electronic products, and stainless steel stamped parts can contribute significantly to this aspect. In high – performance electronics such as gaming consoles and graphics cards, stainless steel – stamped heat sinks are employed. These heat sinks are stamped with intricate fin designs to maximize the surface area for heat dissipation. The good thermal conductivity of stainless steel, combined with its resistance to corrosion, allows for efficient transfer of heat from the heat – generating components, such as processors and graphics processing units (GPUs), to the surrounding environment.

For example, in gaming laptops, stainless steel – stamped heat sinks are attached to the processors and GPUs to prevent overheating during intense gaming sessions. The stamping process enables the production of heat sinks with precise dimensions, ensuring a perfect fit and optimal heat transfer. Additionally, stainless steel – stamped heat – conducting plates can be used to enhance the thermal contact between components and heat sinks, further improving the overall thermal management performance of the electronic devices.

4. Stainless Steel Stamped Parts: Improving Aesthetic Appeal

Aesthetic appeal is an important factor in the design of electronic products, and stainless steel stamped parts can greatly enhance the visual appearance of devices. Stainless steel – stamped decorative trims, covers, and logos are often used to add a touch of elegance and sophistication. In smartwatches, for example, stainless steel – stamped bezels and bands not only provide durability but also give the device a luxurious look. The smooth and shiny surface of stainless steel can be further polished or brushed to create different visual effects, meeting the diverse aesthetic preferences of consumers.

In desktop computers and audio equipment, stainless steel – stamped grilles are used to cover speakers and ventilation holes. These grilles not only protect the internal components but also add a modern and stylish element to the product design. The precision of the stamping process allows for the creation of grilles with intricate patterns and designs, enhancing the overall aesthetic appeal of the electronic products.

5. Stainless Steel Stamped Parts: Driving Innovation in Product Design

As the electronics industry continues to evolve, stainless steel stamped parts are at the forefront of driving innovation in product design. Advanced stamping technologies, combined with the unique properties of stainless steel, enable us to create parts with complex geometries and novel features. For example, we can stamp stainless steel into ultra – thin and flexible shapes to meet the requirements of foldable electronics, such as foldable smartphones and tablets.

The use of stainless steel also promotes sustainability in electronics manufacturing. Its high recyclability reduces the environmental impact of production and disposal. Moreover, new surface treatment and coating technologies for stainless steel stamped parts, such as PVD (Physical Vapor Deposition) coatings, can endow parts with additional functions, such as anti – fingerprint, anti – scratch, and enhanced conductivity. By continuously exploring and applying new stamping techniques and material enhancements, we can drive innovation in electronic product design, bringing forth more advanced, user – friendly, and sustainable electronic devices.