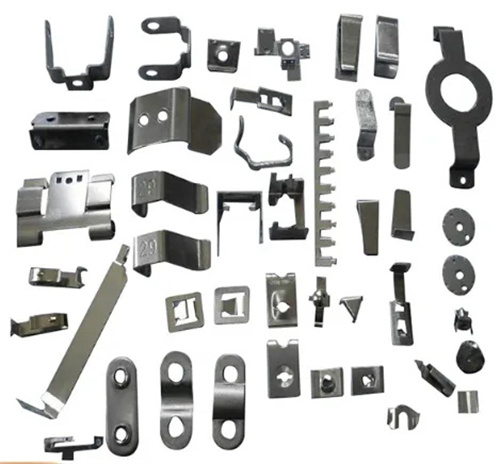

In the rapidly advancing field of electrical products, stainless steel stamped parts have emerged as essential components that significantly enhance the performance, durability, and safety of various devices. These precisely crafted parts, formed by stamping stainless steel sheets under high pressure, combine the remarkable properties of stainless steel, such as corrosion resistance, strength, and electrical conductivity, with the precision of modern manufacturing techniques. From ensuring secure electrical connections to providing robust structural support, stainless steel stamped parts play a crucial role in our pursuit of creating high – quality, reliable, and innovative electrical products. They have seamlessly integrated into our production processes, enabling us to deliver electrical solutions that meet the diverse and evolving needs of the market.

1. Stainless Steel Stamped Parts: Ensuring Secure Electrical Connections

One of the primary applications of stainless steel stamped parts in electrical products is in establishing and maintaining secure electrical connections. We rely on stainless steel – stamped connectors, terminals, and contacts to facilitate the transmission of electrical signals and power. In circuit boards, stainless steel – stamped terminal blocks are commonly used to connect wires and components. These terminal blocks are designed with precise holes and clamping mechanisms, allowing for a firm and reliable connection. The corrosion – resistant nature of stainless steel ensures that the terminal blocks remain functional even in humid or corrosive environments, preventing oxidation and ensuring stable electrical conductivity over time.

For example, in outdoor electrical installations, such as street lighting systems, stainless steel – stamped connectors are used to link electrical cables. These connectors can withstand exposure to rain, moisture, and harsh weather conditions without deteriorating, ensuring a continuous and safe electrical supply. Additionally, in automotive electrical systems, stainless steel – stamped battery terminals provide a secure connection between the battery and the vehicle’s electrical components. The high strength of stainless steel allows the terminals to withstand the vibrations and shocks experienced during vehicle operation, reducing the risk of loose connections and electrical failures.

2. Stainless Steel Stamped Parts: Enhancing Thermal Management

Thermal management is a critical aspect of electrical product design, and stainless steel stamped parts can contribute significantly to this area. In high – power electrical devices, such as power supplies and servers, stainless steel – stamped heat sinks are often employed. These heat sinks are stamped with intricate fin patterns to maximize the surface area available for heat dissipation. The good thermal conductivity of stainless steel, combined with its resistance to corrosion, enables efficient heat transfer from the heat – generating components to the surrounding environment.

For instance, in data center servers, stainless steel – stamped heat sinks are attached to processors and other high – heat – generating components. The stamping process allows for the creation of heat sinks with precise dimensions and shapes, ensuring a perfect fit and optimal heat dissipation. The durability of stainless steel ensures that the heat sinks remain effective over the long lifespan of the server, preventing overheating and maintaining the stable operation of the electrical device. Moreover, stainless steel – stamped heat – conducting pads can be used to enhance the thermal contact between components and heat sinks, further improving the overall thermal management performance.

3. Stainless Steel Stamped Parts: Providing Structural Support

Stainless steel stamped parts offer essential structural support for electrical products, helping to maintain their integrity and withstand various environmental and mechanical stresses. In electrical enclosures, such as switchgear cabinets and control boxes, stainless steel – stamped frames and panels are used to construct the outer shell. These parts are stamped from high – strength stainless steel, providing excellent protection against impacts, dust, and moisture.

For example, in industrial control panels, stainless steel – stamped frames provide a rigid structure that can support the weight of internal components, such as circuit boards, relays, and connectors. The corrosion – resistant property of stainless steel ensures that the enclosures remain in good condition even in harsh industrial environments, protecting the sensitive electrical components inside. Additionally, stainless steel – stamped brackets and mounts are used to secure internal components in place, preventing them from shifting or vibrating during operation, which could lead to electrical failures or damage to the components.

4. Stainless Steel Stamped Parts: Ensuring Electrical Insulation and Safety

While stainless steel is conductive, with proper design and treatment, stainless steel stamped parts can also contribute to electrical insulation and safety in electrical products. We use stainless steel – stamped parts with insulating coatings or in combination with insulating materials to prevent electrical shorts and ensure user safety. In electrical connectors, for example, stainless steel – stamped contacts can be coated with insulating materials to prevent accidental contact with live electrical parts.

In addition, stainless steel – stamped enclosures can be designed with insulating barriers and gaskets to separate different electrical circuits and prevent the leakage of electrical current. The high strength and durability of stainless steel ensure that the enclosures can withstand the mechanical stresses associated with maintaining proper insulation. For instance, in electrical appliances used in households, stainless steel – stamped covers with insulating linings are used to protect users from electrical shocks, providing an additional layer of safety.

5. Stainless Steel Stamped Parts: Driving Innovation in Electrical Product Design

As the electrical product industry continues to evolve, stainless steel stamped parts are at the forefront of driving innovation in design. Advanced stamping technologies, combined with the unique properties of stainless steel, enable us to create parts with complex geometries and innovative features. For example, we can stamp stainless steel into intricate shapes to create customized electrical enclosures that meet specific design requirements, such as those for compact and portable devices.

The use of stainless steel also allows for the development of more sustainable electrical products. Its recyclability makes it an environmentally friendly choice, reducing the environmental impact of product manufacturing and disposal. Moreover, new surface treatment and coating technologies for stainless steel stamped parts can improve their aesthetic appearance, corrosion resistance, and functionality. By continuously exploring and applying new stamping techniques and material enhancements, we can drive innovation in electrical product design, bringing forth more advanced, efficient, and user – friendly electrical products that meet the evolving needs of consumers.