In the intricate and rapidly evolving field of electrical products, spring steel stamped parts have emerged as indispensable components that significantly contribute to the functionality, reliability, and durability of various devices. These precisely crafted parts, formed by stamping spring steel sheets under high pressure, combine the excellent elastic properties and strength of spring steel with the precision of the stamping process. From ensuring stable electrical connections to enhancing the structural integrity of enclosures, spring steel stamped parts play a crucial role in our efforts to create high – quality electrical products that meet the diverse demands of modern applications. They have seamlessly integrated into our manufacturing processes, enabling us to produce electrical solutions that are both efficient and long – lasting.

1. Spring Steel Stamped Parts: Ensuring Stable Electrical Connections

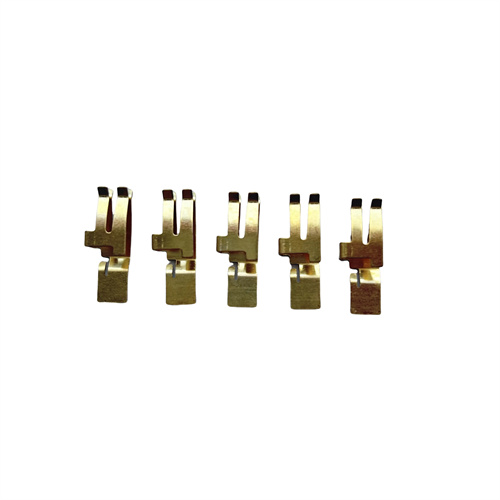

One of the primary applications of spring steel stamped parts in electrical products is in establishing and maintaining stable electrical connections. We rely on spring steel – stamped connectors, terminals, and contacts to facilitate the transmission of electrical signals and power. In circuit boards, spring – loaded terminals made from spring steel are commonly used to connect wires and components. These terminals are designed with a spring mechanism that applies consistent pressure, ensuring a low – resistance and reliable electrical connection.

For example, in power distribution systems, spring steel – stamped blade connectors are used to connect cables to electrical panels. The springy nature of these connectors allows them to adapt to temperature changes and vibrations, preventing loose connections that could lead to electrical failures or overheating. The stamping process enables the creation of connectors with precise geometries, ensuring a perfect fit for different wire gauges and facilitating easy installation and maintenance. By using spring steel stamped parts for electrical connections, we can enhance the reliability and safety of electrical products, reducing the risk of malfunctions and electrical hazards.

2. Spring Steel Stamped Parts: Enhancing Thermal Management

Thermal management is a critical aspect of electrical product design, and spring steel stamped parts can play a supporting role in this regard. In high – power electrical devices such as power supplies and servers, spring steel – stamped brackets are used to mount heat sinks. These brackets are stamped with precise shapes and dimensions to securely hold the heat sinks in place while allowing for proper air circulation around them. The elasticity of spring steel ensures that the brackets can accommodate the thermal expansion and contraction of the heat sinks and the device components without loosening.

For instance, in a server rack, spring steel – stamped clips are used to attach fin – type heat sinks to the processors. The clips, with their spring – loaded design, provide a firm grip on the heat sinks, ensuring efficient heat transfer from the hot components to the heat – dissipating surfaces. Additionally, spring steel – stamped heat – conducting pads can be used to enhance the thermal contact between the components and the heat sinks. These pads, stamped from thin spring steel sheets with a high – thermal – conductivity coating, conform to the surfaces of the components, reducing thermal resistance and improving the overall heat – dissipation efficiency of the electrical products.

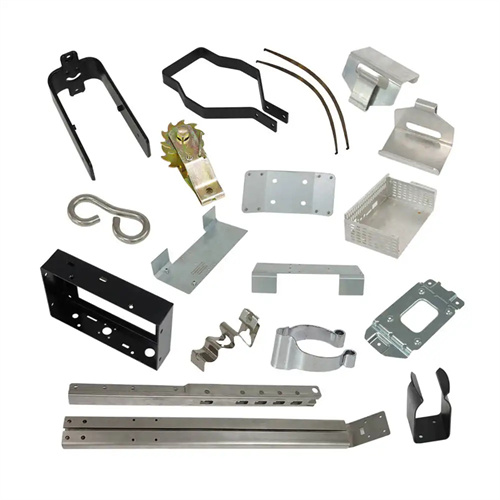

3. Spring Steel Stamped Parts: Providing Structural Support and Protection

Spring steel stamped parts offer essential structural support and protection for electrical products. In electrical enclosures, such as switchgear cabinets and control boxes, spring steel – stamped frames and panels are used to provide a robust and durable structure. These parts are stamped from high – strength spring steel, which can withstand mechanical shocks, vibrations, and external impacts.

For example, in industrial control panels, spring steel – stamped metal frames are designed with reinforced corners and mounting holes. The springy property of the steel allows the frames to absorb impacts and return to their original shape, protecting the internal electrical components from damage. Additionally, spring steel – stamped covers and doors for electrical enclosures are equipped with spring – loaded latches and hinges. These components ensure a secure closure, preventing dust, moisture, and unauthorized access to the internal parts, thereby enhancing the reliability and lifespan of the electrical products.

4. Spring Steel Stamped Parts: Facilitating Component Alignment and Retention

In the assembly of electrical products, spring steel stamped parts are crucial for facilitating component alignment and retention. Spring steel – stamped clips and retainers are used to hold various components in place, ensuring proper positioning and preventing movement during operation. In printed circuit board (PCB) assemblies, for example, spring steel – stamped component clips are used to secure integrated circuits, connectors, and other electronic components.

These clips are designed to provide a secure grip while allowing for easy installation and removal of the components. The springy nature of the steel ensures that the clips can apply the right amount of pressure to hold the components firmly without causing damage. In addition, spring steel – stamped alignment pins are used to ensure precise positioning of PCBs within enclosures or during the assembly of multi – board systems. By using spring steel stamped parts for component alignment and retention, we can improve the assembly efficiency and quality of electrical products, reducing the likelihood of errors and failures.

5. Spring Steel Stamped Parts: Driving Innovation in Electrical Product Design

As the electrical product industry continues to innovate, spring steel stamped parts are at the forefront of driving design advancements. Advanced stamping technologies, combined with the unique properties of spring steel, enable us to create parts with complex geometries and innovative features. For example, we can stamp spring steel into intricate shapes to create flexible electrical contacts that can adapt to different connection requirements.

In the development of smart electrical devices, spring steel – stamped parts can be integrated with sensors and actuators to create self – adjusting and self – monitoring components. The use of spring steel also allows for the development of compact and lightweight electrical products, as the material’s high strength – to – weight ratio enables the creation of robust structures with reduced material usage. Moreover, by exploring new surface treatment and coating technologies for spring steel stamped parts, we can improve their corrosion resistance, electrical conductivity, and aesthetic appearance, opening up new possibilities for creating more advanced, efficient, and reliable electrical products.