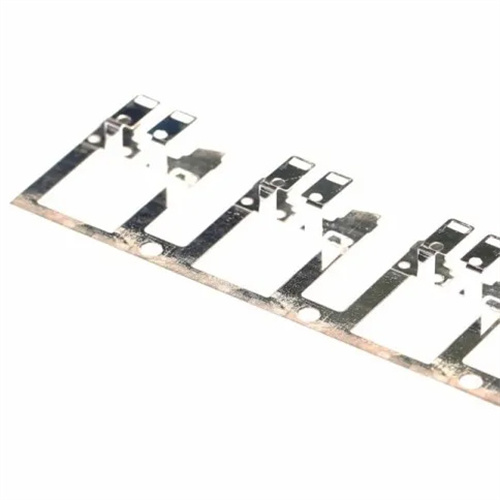

Terminal Connectors

Terminal Connectors are essential components used to establish secure and reliable electrical connections between wires, cables, and devices. They ensure efficient power transfer, signal transmission, and secure connections, making them critical for the proper functioning of electrical and electronic systems. Terminal Connectors are widely used in industries where consistent performance, durability, and ease of installation are required.

In addition, terminal connectors have wide applications in multiple fields. For example, its presence can be seen in electronic products such as mobile phones, tablets, routers, and automotive electronic devices. In medical equipment, electronic connector terminals are also widely used due to the need for high-quality and highly reliable connectors. In the industrial control industry, such as robots, CNC machine tools, and other equipment, electronic connector terminals also play a crucial role.

Features of Terminal Connectors

Terminal Connectors are characterized by their high conductivity, durability, and ease of installation. They are designed to maintain consistent electrical contact, even under mechanical stress or vibration. The connectors are often made from materials with excellent electrical and thermal properties, ensuring efficient power transfer and heat dissipation. They are also customizable in terms of size, shape, and material to meet specific application requirements.

Materials Used in Terminal Connectors

Terminal Connectors are typically made from materials with high electrical conductivity and corrosion resistance. Common materials include copper, brass, phosphor bronze, beryllium copper, and stainless steel. These materials are chosen for their ability to provide reliable electrical connections, withstand environmental factors, and maintain mechanical strength over time. Plating materials such as gold, silver, or nickel are often applied to enhance conductivity and corrosion resistance.

Production Process of Terminal Connectors

The production of Terminal Connectors involves several steps. First, engineers design the connector based on the specific requirements of the application. The appropriate material is then selected, and the metal sheet or wire is cut into the desired shape using stamping, laser cutting, or wire forming. The connector is then formed, bent, or stamped to create the necessary contact points and mounting features. Additional processes like plating (e.g., gold, silver, or nickel plating) may be applied to enhance conductivity and corrosion resistance. Finally, the connectors are inspected for quality, including electrical conductivity, dimensional accuracy, and surface finish.

Applications of Terminal Connectors

LED Lighting In the LED lighting industry, Terminal Connectors are used to establish electrical connections in lighting systems, such as LED panels, strips, and fixtures. They ensure reliable power transfer, enabling consistent performance and long-lasting operation of LED lighting. Examples include connectors for wiring LED modules and securing power cables. Electronics In the electronics industry, Terminal Connectors are used in devices such as circuit boards, power supplies, and consumer electronics. They provide secure and efficient electrical connections, ensuring uninterrupted power supply and optimal device performance. Examples include connectors for PCB terminals, wire harnesses, and power adapters. Electrical Appliances

In the electrical appliances industry, Terminal Connectors are used in devices like washing machines, refrigerators, and air conditioners. They ensure reliable power transfer, enhancing the functionality and lifespan of the appliances. Examples include connectors for motor connections, control panels, and internal wiring.

Toy

In the toy industry, Terminal Connectors are used in battery-powered toys, such as remote-controlled cars, drones, and interactive toys. They provide durable and secure electrical connections, ensuring consistent performance and safety for children’s toys. Examples include connectors for battery compartments and motor connections.

Electrical Appliances

In the electrical appliances industry, Terminal Connectors are used in devices like washing machines, refrigerators, and air conditioners. They ensure reliable power transfer, enhancing the functionality and lifespan of the appliances. Examples include connectors for motor connections, control panels, and internal wiring.

Toy

In the toy industry, Terminal Connectors are used in battery-powered toys, such as remote-controlled cars, drones, and interactive toys. They provide durable and secure electrical connections, ensuring consistent performance and safety for children’s toys. Examples include connectors for battery compartments and motor connections.

Home Appliances

In the home appliances industry, Terminal Connectors are used in devices like cordless phones, smart home devices, and portable fans. These connectors ensure reliable power connections, contributing to the efficient operation and longevity of home appliances. Examples include connectors for charging ports, power switches, and internal wiring.

Terminal Connectors are essential components in industries such as LED lighting, electronics, electrical appliances, toys, and home appliances. Their ability to provide reliable electrical connections, durability, and customization makes them ideal for a wide range of applications. As a manufacturer, leveraging advanced materials and production techniques for Terminal Connectors can help you meet the diverse needs of your clients while maintaining high standards of quality and performance.

Home Appliances

In the home appliances industry, Terminal Connectors are used in devices like cordless phones, smart home devices, and portable fans. These connectors ensure reliable power connections, contributing to the efficient operation and longevity of home appliances. Examples include connectors for charging ports, power switches, and internal wiring.

Terminal Connectors are essential components in industries such as LED lighting, electronics, electrical appliances, toys, and home appliances. Their ability to provide reliable electrical connections, durability, and customization makes them ideal for a wide range of applications. As a manufacturer, leveraging advanced materials and production techniques for Terminal Connectors can help you meet the diverse needs of your clients while maintaining high standards of quality and performance.