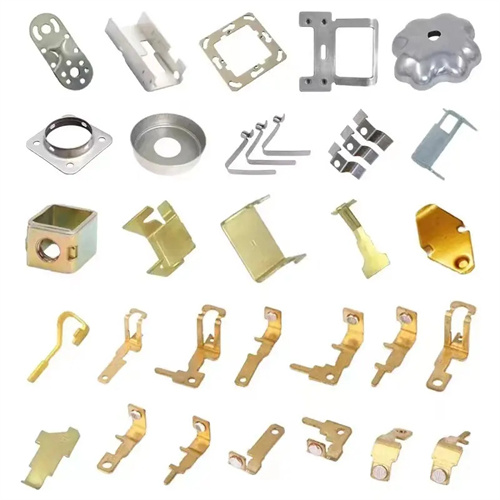

Precision Stamped Parts

In our factory, precision stamping parts are renowned for their high precision and stability. With independently developed high-precision stamping molds and advanced CNC stamping equipment, the dimensional accuracy of parts can reach ± 0.005mm, which can meet micrometer level tolerance requirements and ensure precise adaptation of products in complex assembly environments. Our factory is equipped with a constant temperature and humidity production workshop, which effectively controls the impact of environmental factors on processing accuracy. At the same time, it adopts automated production processes and online detection systems to monitor the production process in real time, ensuring the consistency of product quality for each batch. In addition, precision stamping parts have high surface smoothness and do not require excessive subsequent processing, greatly improving production efficiency, reducing overall costs, and providing customers with cost-effective solutions.

Precision Stamped Parts Material Selection

To ensure the quality of precision stamped parts, we are extremely strict in material selection. Metal materials include stainless steel, alloy steel, spring steel, copper alloy, aluminum alloy, etc. At the same time, special alloy materials such as titanium alloy and magnesium alloy can be purchased according to customer needs. For example, for precision connectors in the electronics industry, copper alloys with high conductivity and good oxidation resistance are selected; The components in the aerospace field are made of high-strength and low-density titanium alloys. All materials are sourced from high-quality suppliers both domestically and internationally, and undergo strict incoming inspections, including chemical composition analysis, metallographic structure testing, mechanical property testing, etc., to ensure that the materials meet precision machining requirements and lay the foundation for product quality from the source.

Precision Stamped Parts Production Process

Our factory has established a complete and strict production process for precision stamped parts. Firstly, the technical team uses CAD/CAM software to design and optimize molds based on customer drawings and technical requirements. The molds are manufactured using high-precision equipment such as CNC machining centers and slow wire cutting to ensure that the mold accuracy reaches the micrometer level. After being cut by high-precision laser cutting machines or CNC shearing machines, the raw materials enter the stamping process. The stamping equipment is equipped with a high-precision servo control system, which can accurately control pressure, speed, and stroke to ensure the accuracy of part forming. During the production process, a visual inspection system is used to perform real-time dimensional measurement and visual inspection of parts. Once any non-conforming products are found, they will be automatically removed. After forming, the parts still need to undergo fine processing such as deburring, cleaning, and shaping. Finally, they are subjected to full-scale inspection and performance testing using precision testing equipment such as coordinate measuring machines and image measuring instruments. Only after passing the inspection can they be packaged and shipped out of our factory.

Precision Stamped Parts Surface Treatment

To meet the needs of different application scenarios, we offer a diverse range of surface treatment processes. In terms of corrosion resistance, chemical nickel plating, vacuum titanium plating, Dacromet coating treatment, etc. can be carried out to effectively improve the corrosion resistance of parts; For products in the fields of optics and electronics, processes such as mirror polishing and electrolytic polishing are used to ensure surface smoothness and optical performance; If surface hardness and wear resistance need to be enhanced, surface treatment techniques such as ion nitriding and chemical vapor deposition (CVD) can be used. In addition, decorative surface treatments such as electrophoretic coating and anodizing are also provided to give the parts a beautiful appearance and personalized colors, meeting the diverse needs of customers.

Precision Stamped Parts Product Applications

The precision stamped parts we produce are widely used in high-end manufacturing fields. In the electronic communication industry, precision connectors, shielding covers, heat sinks, etc. are used to manufacture electronic products such as mobile phones and computers, ensuring the stability of signal transmission and the heat dissipation performance of equipment; In the field of medical devices, customized production of precision components such as heart stents and orthopedic implants meets the strict requirements of medical devices for high precision and biocompatibility; In the aerospace field, precision stamped parts are applied to key parts such as aircraft engine blades and aircraft structural components, helping to achieve the design goals of lightweight and high-strength; In addition, in industries such as automotive electronics, semiconductor packaging, and smart wearable devices, our precision stamped parts have become the preferred products for many customers due to their excellent performance and reliable quality.