The Value of Low-Minimum Stamped Metal Parts Service in Product Development

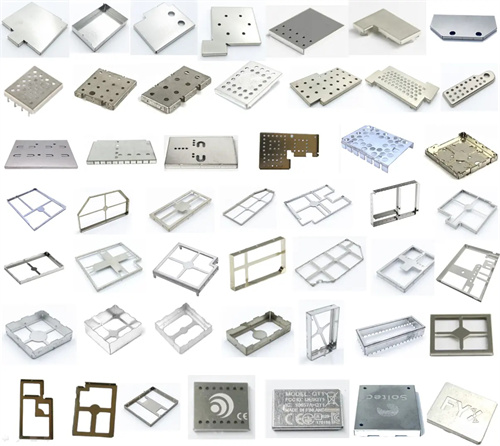

In the dynamic landscape of modern manufacturing, the journey from prototype to production often presents unique challenges, especially when it comes to stamped metal parts. Many businesses, from startups to established companies, require small – scale production runs or prototypes to test their designs, validate concepts, or serve niche markets. Our low – minimum stamped metal parts service fills this crucial gap, offering a flexible and cost – effective solution.

Traditional manufacturing often demands high – volume orders, which can be a barrier for those seeking to develop new products or make quick design iterations. Our service allows clients to order stamped metal parts with low minimum quantities, reducing upfront costs and minimizing the risk associated with large – scale production before a design is fully refined. Whether it’s for a new automotive component, an innovative electronic device, or a specialized industrial part, our low – minimum service enables businesses to bring their ideas to life without the burden of excessive inventory or high initial investment.

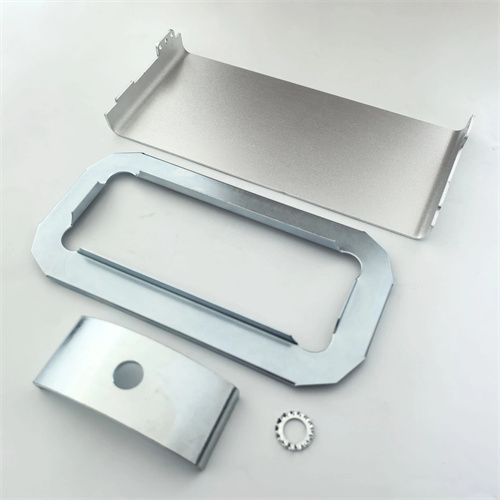

Crafting Precise Prototypes of Stamped Metal Parts

The prototype stage is a critical phase in the development of stamped metal parts, and we approach it with meticulous attention to detail. Our team of experienced designers and engineers works closely with clients to understand their requirements, translating concepts into detailed 3D models using advanced computer – aided design (CAD) software. We take into account factors such as material properties, part functionality, and manufacturability during the design process.

Once the design is finalized, we leverage our state – of – the – art manufacturing capabilities to produce high – quality prototypes of stamped metal parts. We use a variety of techniques, including rapid prototyping methods and small – batch stamping, to create accurate representations of the final product. Our precision – engineered dies and advanced stamping equipment ensure that the prototypes closely match the design specifications, allowing clients to test the form, fit, and function of their parts before moving on to full – scale production. This iterative process of prototype development helps to identify and address any design flaws early, saving time and costs in the long run.

Transitioning Seamlessly from Prototype to Production of Stamped Metal Parts

Making the transition from prototype to production of stamped metal parts requires a seamless and efficient process, and we have the expertise to ensure a smooth journey. Based on the feedback and testing results from the prototype phase, our team refines the design and optimizes the manufacturing process for mass production. We carefully select the most suitable materials, dies, and stamping techniques to meet the production requirements while maintaining the part’s quality and performance.

Our production facilities are equipped with advanced stamping presses and automated systems that can handle both low – and high – volume orders. We have established streamlined workflows and quality control measures to ensure that the transition from prototype to production is as seamless as possible. Whether it’s scaling up production from a few dozen parts to thousands, we have the capacity and flexibility to meet our clients’ needs, delivering stamped metal parts that are consistent with the approved prototype and ready for integration into their products.

Quality Assurance in Low-Minimum Stamped Metal Parts Service

Quality is at the core of our low – minimum stamped metal parts service, regardless of the order quantity. From the prototype stage to full – scale production, we implement a comprehensive quality management system. At the material sourcing stage, we carefully select high – quality metal sheets from trusted suppliers, conducting rigorous tests to verify their chemical composition, mechanical properties, and surface quality.

During the manufacturing process, our skilled technicians use advanced measuring tools, such as coordinate measuring machines (CMMs) and optical comparators, to conduct in – line inspections. Statistical process control (SPC) techniques are employed to monitor and analyze production data, allowing us to identify and correct any potential issues in real – time. After production, each stamped metal part undergoes a final inspection, including functional testing, dimensional checks, and visual inspections. By adhering to strict quality standards, we ensure that our low – minimum stamped metal parts service delivers products that meet or exceed our clients’ expectations.

Cost – Effective Solutions in Low-Minimum Stamped Metal Parts Production

Our low – minimum stamped metal parts service is not only flexible but also highly cost – effective. We understand that small – scale production runs can be costly, especially when it comes to tooling and setup. To address this, we optimize our manufacturing processes to reduce costs without compromising on quality. We use innovative die – making techniques and efficient material utilization strategies to minimize tooling expenses and waste.

For low – minimum orders, we leverage our economies of scale across multiple projects, spreading the fixed costs associated with setup and equipment usage. Additionally, our in – house design and engineering capabilities allow us to identify cost – saving opportunities during the design phase, such as simplifying part geometries or choosing more cost – effective materials. By offering competitive pricing for low – minimum stamped metal parts, we enable our clients to achieve their production goals while managing their budgets effectively.

Future Directions of Our Low-Minimum Stamped Metal Parts Service

As the manufacturing industry continues to evolve, we are committed to enhancing our low – minimum stamped metal parts service to meet the changing needs of our clients. We are constantly exploring new technologies and manufacturing techniques to improve the speed, precision, and efficiency of our prototype and production processes. The integration of artificial intelligence (AI) and machine learning (ML) into our design and manufacturing systems is on the horizon, which will enable us to optimize designs, predict maintenance needs, and improve production quality.

We also aim to expand our material offerings, incorporating new alloys and advanced materials to meet the diverse requirements of different industries. With the growing trend towards sustainable manufacturing, we are actively researching and implementing eco – friendly practices in our production processes. By staying at the forefront of innovation and industry trends, we are dedicated to providing the most advanced and reliable low – minimum stamped metal parts service, supporting our clients’ product development and production needs well into the future.