The Versatility of Custom Stamped Metal Parts in Various Materials

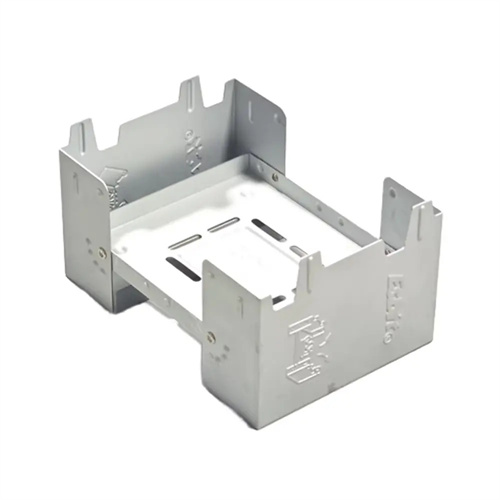

In the dynamic world of manufacturing, custom stamped metal parts have emerged as indispensable components, and the choice of materials—steel, aluminum, copper, and various alloys—adds to their versatility. Each material brings unique properties to the table, making them suitable for a wide range of applications. Steel is renowned for its strength and durability, making it ideal for heavy-duty applications where components need to withstand significant loads and stresses. Aluminum, on the other hand, offers a high strength-to-weight ratio, making it a popular choice for industries that prioritize lightweight solutions without sacrificing strength. Copper is valued for its excellent electrical and thermal conductivity, while alloys combine the best properties of multiple metals to meet specific performance requirements.

Our ability to work with these diverse materials allows us to create custom stamped metal parts that are tailored to the exact needs of our clients. Whether it’s a part for an automotive engine, an electrical connector, or a structural component in a building, we can select the most appropriate material and stamping process to ensure optimal performance, reliability, and cost-effectiveness.

Steel Stamped Metal Parts: Strength and Durability in Manufacturing

Steel stamped metal parts are the backbone of many manufacturing applications, thanks to their exceptional strength and durability. High-carbon steels offer superior hardness and wear resistance, making them suitable for parts that experience frequent friction and mechanical stress, such as gears, shafts, and cutting tools. Low-carbon steels, with their good formability, are often used for components that require complex shapes and bends, like brackets and enclosures.

In the automotive and construction industries, steel stamped parts play a crucial role. In cars, they are used in chassis frames, suspension components, and engine parts, providing the necessary structural support to withstand the rigors of daily use and collisions. In construction, steel stamped metal parts are employed in building frames, bridges, and heavy machinery, ensuring stability and safety under heavy loads. We carefully select the grade of steel based on the application’s requirements and use advanced stamping techniques to shape it into precise components, maintaining the material’s strength and integrity throughout the process.

Aluminum Stamped Metal Parts: Lightweight and Corrosion-Resistant Solutions

Aluminum stamped metal parts have gained widespread popularity due to their lightweight nature and excellent corrosion resistance. The low density of aluminum makes it an ideal material for industries where reducing weight is essential, such as aerospace, automotive, and electronics. In aircraft, aluminum stamped parts are used in fuselage structures, wings, and interior components, helping to reduce fuel consumption and increase payload capacity.

The natural oxide layer that forms on the surface of aluminum provides inherent corrosion resistance, making it suitable for outdoor applications and environments where moisture and chemicals are present. In the automotive industry, aluminum stamped parts are used in body panels, engine blocks, and heat exchangers, improving fuel efficiency and extending the vehicle’s lifespan. Our stamping processes for aluminum are optimized to take advantage of its formability while ensuring tight tolerances and high precision, delivering lightweight and reliable components to our clients.

Copper Stamped Metal Parts: Harnessing Electrical and Thermal Conductivity

Copper stamped metal parts are highly valued for their outstanding electrical and thermal conductivity, making them essential in the electrical and electronics industries. In electrical wiring, connectors, and circuit boards, copper’s low electrical resistance ensures efficient power transmission and signal integrity. Its high thermal conductivity also makes it an excellent choice for heat sinks and cooling components, effectively dissipating heat generated by electronic devices.

We manufacture copper stamped parts with precision to meet the strict requirements of these industries. Our stamping techniques allow us to create complex shapes and fine details, such as thin contacts and intricate patterns on circuit boards. Additionally, we can apply surface treatments to copper parts to enhance their corrosion resistance and electrical performance. Whether it’s for a small electronic device or a large-scale power distribution system, our copper stamped metal parts provide reliable and efficient solutions.

Manufacturing Process of Custom Stamped Metal Parts

The manufacturing process of custom stamped metal parts involves a series of precise steps to ensure the production of high-quality components. It all begins with the design phase, where our team of experts works closely with clients to understand their requirements and translate them into detailed 3D models using advanced computer-aided design (CAD) software. These designs are then optimized for the stamping process, taking into account factors such as material flow, die design, and part functionality.

Next, we select the appropriate material—steel, aluminum, copper, or an alloy—and prepare it for stamping. The material is fed into our state-of-the-art stamping presses, which are equipped with custom-made dies. The dies perform operations like punching, bending, and forming to shape the metal into the desired part. Throughout the stamping process, we closely monitor parameters such as temperature, pressure, and speed to ensure consistent quality. After stamping, parts may undergo additional processes like deburring, finishing, and surface treatment to meet the final specifications.

Quality Assurance and Future Trends of Custom Stamped Metal Parts

Quality assurance is at the core of our production of custom stamped metal parts. We implement a comprehensive quality management system that starts with rigorous material inspection, verifying the chemical composition, mechanical properties, and surface quality of each batch. During the manufacturing process, our skilled technicians use advanced measuring tools, such as coordinate measuring machines (CMMs) and optical comparators, to conduct in-line inspections and ensure dimensional accuracy.

After production, parts are subjected to final inspections, including functional testing, fatigue testing, and corrosion resistance testing, depending on the material and application. Looking ahead, we are constantly exploring new materials, manufacturing techniques, and design approaches to stay at the forefront of the industry. The development of advanced alloys, the integration of automation and artificial intelligence in the stamping process, and the focus on sustainable manufacturing practices are some of the trends that will shape the future of custom stamped metal parts, allowing us to provide even better solutions to our clients.