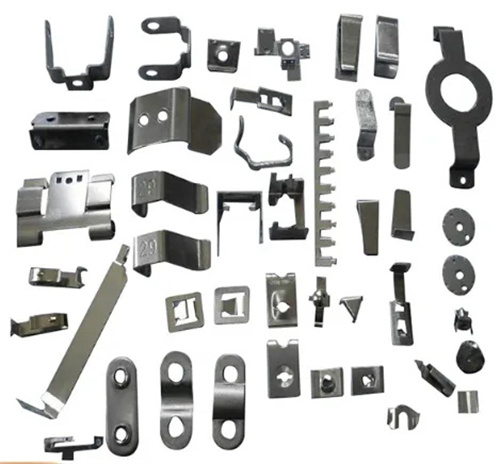

The Significance of Electropolishing and Deburring for Stainless Steel Stamped Parts

In the realm of manufacturing stainless steel stamped parts, electropolishing and deburring are not just additional steps—they are essential processes that transform raw components into high – quality, reliable products. Deburring removes sharp edges, burrs, and other imperfections that form during the stamping process. These burrs can not only cause injuries during handling but also interfere with the proper fit and function of the parts in assemblies. On the other hand, electropolishing goes a step further by enhancing the surface finish of stainless steel stamped parts.

Electropolishing creates a smooth, uniform surface that not only looks aesthetically pleasing but also offers practical benefits. It improves the corrosion resistance of the parts by removing surface contaminants and creating a more consistent passive layer. This process is crucial as it ensures that our stainless steel stamped components meet the stringent requirements of various industries, from food and beverage to medical and aerospace, where hygiene, durability, and performance are of utmost importance.

The Deburring Process: Refining Stainless Steel Stamped Parts

Our deburring process for stainless steel stamped parts is a meticulous operation designed to perfect the edges and surfaces of the components. We utilize a variety of advanced techniques, including mechanical deburring, vibratory deburring, and abrasive flow machining. Mechanical deburring involves using tools such as rotary brushes and files to manually remove burrs from the parts. This method is ideal for larger burrs and can be precisely controlled to avoid damaging the underlying material.

Vibratory deburring, on the other hand, is more suitable for mass – produced stainless steel stamped parts. The parts are placed in a vibrating tub filled with abrasive media, which gently removes burrs as the parts tumble. Abrasive flow machining uses a semi – solid abrasive media that is forced through the part’s channels and openings, effectively deburring internal surfaces. By carefully selecting the appropriate deburring method based on the part’s design and requirements, we ensure that every stainless steel stamped part we produce has smooth, safe edges that are ready for further processing or assembly.

Electropolishing: Elevating the Quality of Stainless Steel Stamped Parts

Electropolishing is a transformative electrochemical process that takes the quality of our stainless steel stamped parts to new heights. During electropolishing, the parts are immersed in an electrolyte solution and connected to an electrical circuit as the anode. When an electric current is applied, a thin layer of metal on the surface of the part is dissolved, resulting in a smoother and brighter finish. This process not only enhances the visual appeal of the stainless steel stamped components but also improves their functional properties.

The removal of surface imperfections through electropolishing reduces the surface roughness, which in turn minimizes the accumulation of dirt, bacteria, and other contaminants. This makes electropolished stainless steel stamped parts highly suitable for applications in the food processing and medical industries, where hygiene is critical. Additionally, the improved surface finish reduces friction, allowing for smoother movement of parts in mechanical assemblies and increasing their overall efficiency and lifespan.

Applications of Electropolished and Deburred Stainless Steel Stamped Parts

The versatility of electropolished and deburred stainless steel stamped parts makes them indispensable across a wide range of industries. In the food and beverage industry, these components are used in equipment such as conveyor systems, mixing tanks, and food processing machinery. The smooth, non – porous surface created by electropolishing and deburring ensures that food products do not get trapped in crevices, making the parts easy to clean and maintain hygiene standards.

In the medical field, stainless steel stamped parts are used in surgical instruments, implants, and diagnostic equipment. The high – quality surface finish provided by electropolishing reduces the risk of infection and ensures biocompatibility. In the aerospace and automotive sectors, these parts are utilized in engine components, structural frames, and decorative elements. The enhanced corrosion resistance and improved performance of electropolished and deburred stainless steel stamped parts contribute to the overall reliability and safety of vehicles and aircraft.

Quality Assurance in Electropolished and Deburred Stainless Steel Stamped Parts

Quality assurance is at the core of our production process for electropolished and deburred stainless steel stamped parts. We start by carefully selecting high – grade stainless steel materials from trusted suppliers, ensuring that the base material meets our strict quality standards. During the deburring and electropolishing processes, our skilled technicians closely monitor each step to ensure consistency and precision.

We use advanced inspection tools, such as optical microscopes and surface roughness testers, to evaluate the quality of the deburred and electropolished surfaces. Random sampling and rigorous quality checks are carried out at various stages of production to identify and rectify any potential issues promptly. By adhering to international quality standards and implementing a comprehensive quality control system, we guarantee that every stainless steel stamped component we deliver is of the highest quality, reliable, and fit for its intended application.

Future Trends in Electropolished and Deburred Stainless Steel Stamped Parts

As technology continues to evolve, so does the manufacturing of electropolished and deburred stainless steel stamped parts. We are constantly exploring new techniques and technologies to improve the efficiency and effectiveness of our deburring and electropolishing processes. For instance, the integration of automation and robotics in these processes holds great potential for increasing productivity while maintaining high – quality standards.

Research is also underway to develop new electrolyte solutions for electropolishing that are more environmentally friendly and offer enhanced performance. Additionally, the use of advanced materials characterization techniques will allow us to better understand the impact of electropolishing and deburring on the mechanical and physical properties of stainless steel stamped parts. By staying ahead of these trends and embracing innovation, we are committed to providing our customers with the most advanced and reliable electropolished and deburred stainless steel stamped components in the market.