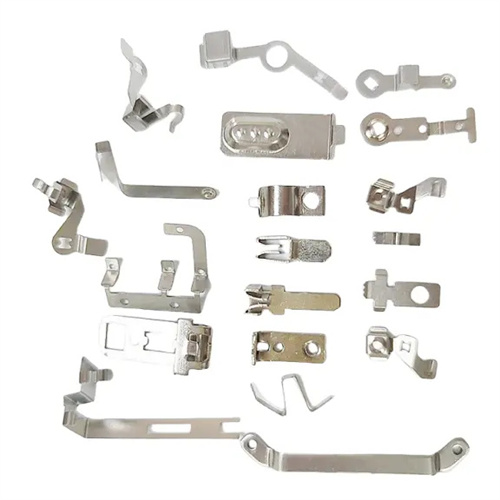

Introduction to Spring Steel Stamped Parts: The Backbone of Precision Components

As a team deeply immersed in the metal manufacturing industry, we understand that Spring Steel Stamped Parts are the backbone of precision – engineered components. In an era where technological advancements demand components with unwavering performance, the combination of precision stamping and spring steel has emerged as a game – changer. Spring steel, renowned for its inherent properties, provides the ideal foundation for creating components that can withstand the most demanding applications.

Our expertise in producing Precision Stamped Spring Steel Components allows us to harness the full potential of this remarkable material. Whether it’s for automotive, aerospace, or industrial machinery, these components play a pivotal role in ensuring smooth operations. We take pride in our ability to deliver parts that not only meet but exceed industry standards, leveraging our in – depth knowledge of spring steel and precision stamping techniques to create solutions that drive innovation and reliability across various sectors.

The Unparalleled Advantages of Spring Steel Stamped Parts: Elasticity and Durability

We are acutely aware of the unparalleled advantages that Spring Steel Stamped Parts offer, particularly in terms of elasticity and durability. The exceptional elasticity of spring steel enables our stamped components to absorb and release energy with remarkable efficiency. This property is crucial in applications where components are subjected to repeated stress, such as in suspension systems or mechanical springs. Our parts can endure continuous compression and extension cycles without losing their shape or performance, ensuring long – term functionality.

Durability is another standout feature of our Spring Steel Stamped Parts. The high strength and fatigue resistance of spring steel make these components capable of withstanding heavy loads, vibrations, and harsh environmental conditions. Whether it’s exposure to extreme temperatures, corrosive elements, or high – frequency mechanical stress, our precision – stamped parts maintain their integrity over extended periods. This durability not only reduces maintenance costs but also enhances the overall lifespan of the systems in which they are integrated, providing our clients with a cost – effective and reliable solution.

The Meticulous Fabrication Process of Spring Steel Stamped Parts

Our fabrication process for Spring Steel Stamped Parts is a meticulous and highly – coordinated endeavor. It begins with in – depth consultations with our clients to fully understand their specific requirements, including the intended application, performance specifications, and design constraints. Our team of experienced engineers then utilizes advanced CAD/CAM software to create detailed 3D models of the components, optimizing the design for maximum functionality, manufacturability, and the unique properties of spring steel.

Once the designs are finalized, we source premium – grade spring steel from trusted suppliers. The steel is then fed into our state – of – the – art precision stamping presses, equipped with custom – made dies. During the stamping process, we closely monitor and control parameters such as pressure, speed, and temperature to ensure consistent quality and dimensional accuracy within extremely tight tolerances. After stamping, the components may undergo additional processes, such as heat treatment to enhance mechanical properties, surface finishing to improve corrosion resistance, and quality inspections to verify compliance with our stringent standards. Each step in the process is carefully executed to ensure that every Spring Steel Stamped Part we produce is of the highest quality.

Applications of Spring Steel Stamped Parts in the Automotive Industry

In the automotive industry, Spring Steel Stamped Parts are integral to the performance and safety of vehicles. In suspension systems, our precision – stamped spring steel components, such as coil springs and leaf springs, provide the necessary support and shock absorption, ensuring a smooth and stable ride. The exceptional elasticity of these parts allows them to adapt to various road conditions, while their durability ensures they can withstand the rigors of daily use over the vehicle’s lifespan.

Engine components also rely heavily on our Spring Steel Stamped Parts. Valve springs, for example, are crucial for the proper operation of the engine’s valves. The high strength and fatigue resistance of our stamped valve springs enable them to endure the high – frequency opening and closing motions, ensuring efficient combustion and power delivery. Additionally, in transmission systems, our spring steel parts play a vital role in maintaining precise gear engagement and smooth shifting. Overall, our Precision Stamped Spring Steel Components contribute significantly to the reliability, performance, and longevity of modern automobiles.

Applications of Spring Steel Stamped Parts in Aerospace and Industrial Sectors

In the aerospace industry, where precision and reliability are non – negotiable, our Spring Steel Stamped Parts are essential components. In aircraft engines, these parts are used in critical applications such as fuel injection systems and engine mounts. The superior elasticity and durability of our stamped components ensure they can withstand the extreme temperatures, pressures, and vibrations encountered during flight, contributing to the safe and efficient operation of the aircraft.

For industrial machinery, our Spring Steel Stamped Parts are widely used in various applications, from heavy – duty presses to conveyor systems. In presses, our precision – stamped springs provide the necessary force for shaping and forming operations, while their durability ensures consistent performance over long production runs. In conveyor systems, our spring steel components, such as tensioners and guides, maintain the proper alignment and tension of the belts, preventing slippage and ensuring smooth material handling. Whether in the skies or on the factory floor, our Precision Stamped Spring Steel Components are trusted to deliver reliable performance in the most demanding environments.

Future Prospects of Spring Steel Stamped Parts: Innovating for Tomorrow

Looking to the future, we are highly optimistic about the prospects of our Spring Steel Stamped Parts. As industries continue to evolve and embrace new technologies, the demand for components with superior elasticity, durability, and precision will only increase. The growth of electric vehicles, the development of advanced aerospace technologies, and the expansion of automation in manufacturing will all drive the need for more innovative and reliable spring steel stamped components.

We are committed to continuous research and development to stay at the forefront of this evolving market. Our team will explore new spring steel alloys with enhanced properties, develop innovative stamping techniques for more complex part geometries, and invest in advanced manufacturing technologies to improve efficiency and precision. By maintaining our focus on quality, innovation, and customer satisfaction, we aim to meet the ever – growing needs of our clients across various industries and remain a leading provider of Precision Stamped Spring Steel Components that deliver superior elasticity and durability.