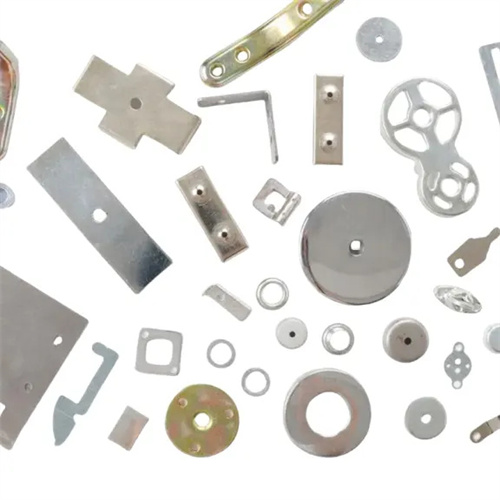

Introduction to Spring Steel Stamped Parts in Medical Device Spring Components

As a team with extensive experience in the medical device component manufacturing field, we understand the critical role that Spring Steel Stamped Parts play in medical device spring components. When precision – stamped from 301/304 stainless steel, these components become essential elements in various medical applications. In the highly regulated and safety – conscious medical industry, the reliability, biocompatibility, and precision of components are of utmost importance.

301/304 stainless steel offers a unique combination of properties that make it ideal for crafting spring components in medical devices. Its excellent corrosion resistance, strength, and formability ensure that our stamped parts can withstand the challenging environments within medical equipment and the human body. We take pride in our ability to produce high – quality Spring Steel Stamped Parts for medical device spring components, adhering to the strictest standards to contribute to the safety and effectiveness of medical treatments.

The Distinctive Advantages of Spring Steel Stamped Parts from 301/304 Stainless for Medical Devices

We are well – aware of the distinctive advantages that Spring Steel Stamped Parts precision – stamped from 301/304 stainless steel bring to medical devices. One of the primary benefits is the exceptional biocompatibility of 301/304 stainless steel. When in contact with bodily fluids and tissues, these materials do not cause adverse reactions, making them suitable for use in implantable devices and components that interact directly with patients.

The corrosion resistance of 301/304 stainless steel is also crucial in medical settings. Medical devices often need to be sterilized repeatedly, and the steel’s resistance to rust and chemical corrosion ensures that our spring components maintain their integrity over time. Additionally, the strength and elasticity of spring steel allow our stamped parts to provide consistent force and movement, which is essential for the proper functioning of medical devices, such as surgical instruments that require precise spring – loaded actions or diagnostic equipment with moving parts. These combined advantages make our Spring Steel Stamped Parts a reliable choice for medical device manufacturers.

The Meticulous Fabrication Process of Spring Steel Stamped Parts for Medical Device Spring Components

Our fabrication process for Spring Steel Stamped Parts used in medical device spring components is a highly meticulous and carefully controlled sequence. It begins with in – depth consultations with medical device manufacturers to fully understand their specific requirements, including the intended application, performance specifications, and regulatory compliance needs. Our team of experienced engineers then utilizes advanced CAD/CAM software to create detailed 3D models of the parts, optimizing the design for functionality, manufacturability, and biocompatibility.

Once the designs are finalized, we source high – quality 301/304 stainless steel from trusted suppliers that meet strict medical – grade material standards. The steel sheets are then fed into our state – of – the – art precision stamping presses, equipped with custom – made dies. During the stamping process, we closely monitor and control parameters such as pressure, speed, and temperature to ensure consistent quality and dimensional accuracy within extremely tight tolerances. After stamping, the parts undergo a series of post – processing operations. This includes thorough cleaning to remove any contaminants, passivation to enhance corrosion resistance, and surface finishing to achieve a smooth, non – reactive surface. Rigorous quality inspections, including non – destructive testing and biocompatibility testing, are carried out at every stage to guarantee that each Spring Steel Stamped Part meets the stringent requirements of the medical industry.

Applications of Spring Steel Stamped Parts in Surgical Instruments

In surgical instruments, our Spring Steel Stamped Parts precision – stamped from 301/304 stainless steel are widely used and play a vital role. For example, in laparoscopic instruments, spring components are essential for the precise opening and closing of graspers, scissors, and other tools. The consistent force provided by our stamped spring parts allows surgeons to perform delicate procedures with accuracy and control.

In orthopedic surgical instruments, such as bone drills and saws, spring – loaded mechanisms rely on our high – quality spring components to ensure smooth operation and proper alignment. The biocompatibility and corrosion resistance of our Spring Steel Stamped Parts ensure that these instruments can be safely sterilized and reused multiple times, reducing costs while maintaining the highest standards of patient care. By providing reliable spring components, we contribute to the advancement of minimally invasive and complex surgical procedures.

Applications of Spring Steel Stamped Parts in Implantable and Diagnostic Medical Devices

In implantable medical devices, our Spring Steel Stamped Parts are crucial for ensuring long – term functionality and patient safety. For instance, in pacemakers, the spring components are used to maintain proper electrical contact and provide the necessary flexibility to adapt to the body’s movements. The biocompatibility of 301/304 stainless steel ensures that these parts do not cause any adverse reactions within the patient’s body over extended periods.

In diagnostic medical devices, such as blood analyzers and imaging equipment, our spring components are used in various mechanisms, from sample handling to precise positioning of components. The precision and reliability of our Spring Steel Stamped Parts ensure accurate and consistent results, which are essential for proper diagnosis and treatment planning. Whether inside the human body or in the laboratory, our spring components contribute to the effectiveness of medical devices across different applications.

Future Prospects of Spring Steel Stamped Parts in Medical Device Spring Components

Looking to the future, we are highly optimistic about the prospects of Spring Steel Stamped Parts in medical device spring components. As the medical industry continues to innovate with the development of new treatment methods, advanced diagnostic technologies, and minimally invasive procedures, the demand for high – quality, precision – stamped spring components will only increase.

We are committed to continuous research and development to stay at the forefront of this evolving market. Our team will explore new ways to optimize the performance of 301/304 stainless steel in spring components, develop even more precise stamping techniques, and invest in advanced manufacturing technologies that can meet the growing complexity of medical device designs. By maintaining our focus on quality, compliance, and innovation, we aim to meet the evolving needs of medical device manufacturers and contribute to the advancement of healthcare with our reliable Spring Steel Stamped Parts.