Introduction to Custom Precision Stamped Parts Fabrication

As a team with extensive experience in metal fabrication, we understand the unique challenges and opportunities that come with crafting small metal parts. Custom Precision Stamped Parts Fabrication for small metal components is a specialized field that demands meticulous attention to detail, advanced technology, and in – depth material knowledge. In today’s competitive market, where precision and miniaturization are highly valued across various industries, our expertise in this area allows us to provide tailored solutions that meet the exacting standards of our clients.

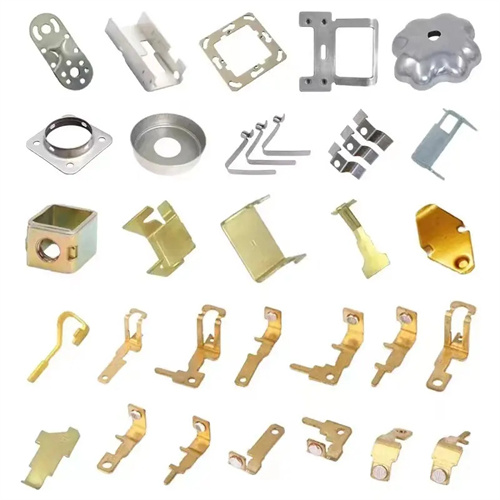

Small metal parts play a crucial role in countless applications, from consumer electronics to medical devices and aerospace systems. Our Custom Precision Stamped Parts are designed to deliver optimal performance, reliability, and functionality, no matter how intricate or tiny the component may be. We take pride in our ability to leverage state – of – the – art stamping techniques and high – quality materials to produce parts that not only meet but exceed industry expectations, contributing to the success of our clients’ projects.

The Unparalleled Advantages of Custom Precision Stamped Parts for Small Metal Parts

We are well – aware of the unparalleled advantages that our Custom Precision Stamped Parts offer for small metal components. One of the most significant benefits is the exceptional level of precision we can achieve. Our advanced stamping equipment, combined with sophisticated die – making technologies, enables us to produce parts with extremely tight tolerances, often down to micrometer levels. This precision is essential in applications where a perfect fit is critical, such as in the assembly of micro – electronics or medical implants.

Another key advantage is the cost – effectiveness of our fabrication process. Despite the high level of precision, our efficient production methods, especially for high – volume runs, allow us to keep costs in check. By using optimized stamping dies and automated processes, we can minimize material waste and production time, making our Custom Precision Stamped Parts an attractive option for businesses looking to balance quality and affordability. Additionally, the repeatability of our stamping process ensures consistent quality across all parts, providing our clients with the confidence that each component will perform reliably in their end – products.

The Meticulous Fabrication Process of Custom Precision Stamped Parts

Our fabrication process for Custom Precision Stamped Parts of small metal components is a highly detailed and carefully orchestrated sequence of steps. It begins with in – depth consultations with our clients to fully understand their specific requirements, including part design, material preferences, performance expectations, and production volumes. Our team of experienced engineers then utilizes advanced CAD/CAM software to create precise 3D models of the parts, optimizing the design for both functionality and manufacturability.

Once the designs are finalized, we source high – quality metal materials, such as stainless steel, brass, aluminum, or specialized alloys, depending on the application. These materials are then fed into our state – of – the – art stamping presses, which are equipped with custom – made precision dies. During the stamping process, we closely monitor and control parameters such as pressure, speed, and temperature to ensure consistent quality and dimensional accuracy. After stamping, the parts may undergo a series of post – processing operations, including deburring, polishing, plating, and heat treatment, to enhance their performance, durability, and appearance. Rigorous quality inspections are carried out at every stage to guarantee that each Custom Precision Stamped Part meets our exacting standards before being delivered to the client.

Applications of Custom Precision Stamped Parts in the Electronics Industry

In the electronics industry, our Custom Precision Stamped Parts are indispensable for the production of a wide range of devices. From smartphones and laptops to wearable technology and advanced communication equipment, small metal components are crucial for functionality, connectivity, and durability. Our precision – stamped parts are used in connectors, terminals, contacts, and heat sinks, where their high level of accuracy ensures reliable electrical connections and efficient heat dissipation.

For example, in micro – connectors used in smartphones, the precision of our stamped parts allows for seamless data transfer and power supply, while also withstanding the rigors of repeated plugging and unplugging. In circuit board components, our custom – made parts provide the necessary support and electrical conductivity, contributing to the overall performance and reliability of the electronic device. The ability to produce small metal parts with such precision makes our Custom Precision Stamped Parts a preferred choice for leading electronics manufacturers worldwide.

Applications of Custom Precision Stamped Parts in the Medical and Aerospace Sectors

In the medical sector, where precision and safety are of utmost importance, our Custom Precision Stamped Parts play a vital role. Small metal components are used in a variety of medical devices, including surgical instruments, diagnostic equipment, and implantable devices. Our precision – stamped parts are crafted with the highest level of accuracy to ensure proper fit, functionality, and biocompatibility.

For implantable devices, such as pacemakers and stents, the precision of our parts is critical for patient safety and long – term performance. In the aerospace industry, our Custom Precision Stamped Parts are essential for the production of aircraft components, avionics systems, and satellite equipment. The extreme conditions in aerospace applications, including high altitudes, temperature fluctuations, and mechanical stresses, demand parts with exceptional precision and durability. Our precision – stamped small metal parts meet these stringent requirements, contributing to the reliability and performance of aerospace systems.

Future Prospects of Custom Precision Stamped Parts Fabrication for Small Metal Parts

Looking to the future, we are highly optimistic about the prospects of our Custom Precision Stamped Parts Fabrication for small metal components. As technology continues to advance, with the growth of the Internet of Things (IoT), artificial intelligence, and miniaturized electronics, the demand for high – precision, small – scale metal parts will only increase. These emerging technologies require components that are not only smaller but also more precise, reliable, and efficient.

We are committed to continuous research and development to stay at the forefront of this evolving market. Our team will explore new materials, innovative stamping techniques, and advanced manufacturing processes to further enhance the precision and performance of our Custom Precision Stamped Parts. By investing in cutting – edge equipment and maintaining a focus on quality, we aim to meet the evolving needs of our clients across various industries and remain a leading provider of custom – fabricated precision stamped parts for small metal components.