Introduction to Custom Stamped Parts in OEM Precision Stamping of Sheet Metal Parts

As a team deeply involved in the metal fabrication industry, we understand the crucial role that OEM Precision Stamping Parts, especially custom – made sheet metal parts, play in various sectors. Our Custom Stamped Parts services offer tailored solutions that combine precision engineering with the versatility of sheet metal. Sheet metal, with its malleability and durability, serves as an ideal material for creating a wide range of components through stamping processes.

In the highly competitive global market, where customization and precision are key, our OEM approach allows us to meet the specific needs of our clients. Whether it’s for automotive, electronics, or industrial applications, the demand for custom – stamped sheet metal parts that fit seamlessly into existing systems is on the rise. We take pride in our ability to leverage advanced stamping technologies and in – depth industry knowledge to produce high – quality Custom Stamped Parts that not only meet but exceed client expectations, providing reliable solutions for their unique projects.

The Unmatched Advantages of Custom Stamped Sheet Metal Parts in OEM Precision Stamping

We are well – aware of the numerous advantages that our Custom Stamped Sheet Metal Parts in OEM precision stamping offer. One of the most significant benefits is the high level of customization. With our OEM services, clients have the freedom to specify every detail of the part, from dimensions and shapes to surface finishes. This ensures that each Custom Stamped Part is a perfect match for their specific application, eliminating the need for costly modifications or adaptations.

Precision is another key advantage. Our state – of – the – art stamping equipment, combined with advanced die – making techniques, enables us to produce sheet metal parts with extremely tight tolerances. This precision is crucial in applications where accurate fit and function are essential, such as in the assembly of complex electronic devices or automotive components. Additionally, the use of sheet metal in our Custom Stamped Parts provides a good balance between strength and weight, making them suitable for a wide range of applications where both durability and lightness are required. The cost – effectiveness of our OEM precision stamping process, especially for large – volume production, further adds to the appeal of our Custom Stamped Sheet Metal Parts.

The Meticulous Manufacturing Process of Custom Stamped Parts

Our manufacturing process for Custom Stamped Parts in OEM precision stamping of sheet metal is a highly detailed and carefully coordinated sequence of steps. It begins with in – depth consultations with our clients to fully understand their project requirements, including design specifications, performance expectations, and production volumes. Our team of experienced engineers then uses advanced CAD/CAM software to create precise 3D models of the parts, optimizing the design for functionality, manufacturability, and cost – effectiveness.

Once the designs are finalized, we source high – quality sheet metal materials from trusted suppliers. These materials are then fed into our precision stamping presses, which are equipped with custom – made dies. During the stamping process, we closely monitor and control parameters such as pressure, speed, and temperature to ensure consistent quality and dimensional accuracy. After stamping, the parts may undergo a series of post – processing operations. This can include deburring to remove sharp edges, bending to achieve specific shapes, welding for assembly, and surface treatments like painting or plating to enhance appearance and corrosion resistance. Rigorous quality inspections are carried out at every stage to guarantee that each Custom Stamped Part meets our strict quality standards before being delivered to the client.

Applications of Custom Stamped Parts in the Automotive Industry

In the automotive industry, our Custom Stamped Parts play a vital role in vehicle manufacturing. Sheet metal parts, such as body panels, structural frames, and brackets, are essential components. Our custom – stamped body panels are designed to fit precisely, providing a smooth exterior and contributing to the vehicle’s aerodynamic performance. The structural frames, crafted through our OEM precision stamping, offer the strength and rigidity needed to ensure passenger safety.

For engine compartments, our Custom Stamped Parts are used to create brackets, connectors, and housings that support various engine components. The precision of these parts ensures proper alignment, reducing vibrations and improving the overall efficiency of the engine. Additionally, in safety – critical systems like seatbelt anchors and airbag enclosures, the reliability and accuracy of our custom – stamped sheet metal parts are crucial. By providing high – quality Custom Stamped Parts, we contribute to the production of safe, reliable, and efficient vehicles.

Applications of Custom Stamped Parts in the Electronics and Industrial Sectors

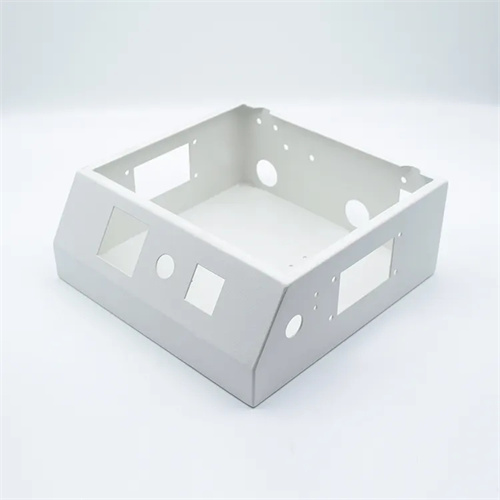

In the electronics industry, our Custom Stamped Parts are widely used in the production of various devices. From smartphone casings and laptop frames to circuit board enclosures, our custom – stamped sheet metal parts offer the precision and protection required. The tight tolerances of our parts ensure a perfect fit for internal components, preventing damage and ensuring proper functionality.

In the industrial sector, our Custom Stamped Parts are essential for manufacturing machinery, equipment, and tools. Sheet metal parts such as enclosures, covers, and brackets are designed to withstand harsh industrial environments. The durability and strength of our custom – stamped parts make them suitable for applications where components need to endure heavy loads, vibrations, and exposure to dust and chemicals. Whether it’s for large – scale manufacturing plants or specialized industrial equipment, our Custom Stamped Parts provide the reliable components that industries rely on for smooth operations.

Future Prospects of Custom Stamped Parts in OEM Precision Stamping

Looking to the future, we are highly optimistic about the prospects of our Custom Stamped Parts in OEM precision stamping. As technology continues to advance and industries become more competitive, the demand for customized, high – performance sheet metal parts will only increase. The growth of electric vehicles, the development of smart electronics, and the expansion of automated industrial processes will all drive the need for more innovative and precise Custom Stamped Parts.

We are committed to continuous research and development to stay at the forefront of this evolving market. Our team will explore new materials, such as advanced lightweight alloys and high – strength steels, to meet the changing requirements of different industries. We will also invest in cutting – edge stamping technologies, including automation and artificial intelligence – driven quality control systems, to further enhance the precision, efficiency, and flexibility of our production. By maintaining our focus on quality and innovation, we aim to meet the evolving needs of our clients and remain a leading provider of OEM Precision Stamping Parts and Custom Stamped Sheet Metal Parts.