Introduction to Custom Stamped Parts Services of Customized Sheet Metal Stamping

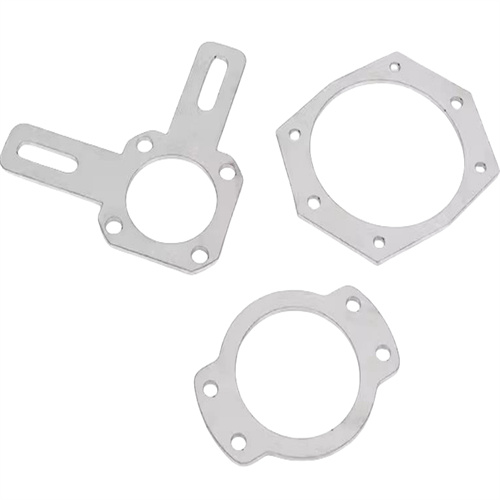

As a team deeply committed to the metal fabrication industry, we understand the diverse and evolving needs of our clients when it comes to custom – made metal components. Our Custom Stamped Parts Services, specializing in customized sheet metal stamping and bending parts, offer tailored solutions that combine precision, efficiency, and quality. Sheet metal stamping is a versatile manufacturing process that allows us to transform flat sheets of metal into complex, three – dimensional shapes, while bending operations add an extra layer of customization to meet specific design requirements.

In today’s competitive market, where one – size – fits – all solutions no longer suffice, our custom – stamped parts services have become essential for various industries. Whether it’s for automotive, electronics, aerospace, or architectural applications, we take pride in our ability to leverage advanced stamping and bending technologies to produce parts that not only meet but exceed industry standards. Our dedication to providing high – quality, customized sheet metal stamped and bent parts has made us a trusted partner for businesses seeking reliable and innovative manufacturing solutions.

The Unmatched Advantages of Custom Stamped Parts Services for Sheet Metal Stamping and Bending

We are well – aware of the numerous advantages that our Custom Stamped Parts Services for sheet metal stamping and bending bring to the table. One of the key benefits is the high level of customization we offer. Our clients have the freedom to specify the exact dimensions, shapes, and features of their parts, ensuring a perfect fit for their unique applications. This flexibility allows us to cater to a wide range of requirements, from simple, standard components to highly complex, specialized parts.

Another significant advantage is the precision and consistency of our manufacturing processes. Our state – of – the – art stamping and bending equipment, combined with our experienced technicians, enables us to produce parts with tight tolerances and uniform quality. The stamping process can create intricate details and shapes with remarkable accuracy, while bending operations are carried out with precision to achieve the desired angles and forms. Additionally, our services are cost – effective, as we can optimize material usage and production efficiency, reducing waste and minimizing costs for our clients without compromising on quality.

The Comprehensive Manufacturing Process of Custom Stamped Parts

Our manufacturing process for Custom Stamped Parts in sheet metal stamping and bending is a comprehensive and well – organized sequence of steps. It begins with in – depth consultations with our clients to fully understand their project requirements, including design specifications, performance expectations, and any specific constraints. Our team of experienced engineers then uses advanced CAD/CAM software to create detailed 3D models of the parts, optimizing the design for functionality, manufacturability, and cost – effectiveness.

Once the designs are finalized, we source high – quality sheet metal materials from trusted suppliers. These materials are then loaded into our stamping presses, where custom – made dies are used to cut, shape, and form the metal sheets into the desired part geometries. During the stamping process, we closely monitor and control parameters such as pressure, speed, and temperature to ensure consistent quality and dimensional accuracy. After stamping, the parts may undergo bending operations using our precision bending machines. Our technicians carefully adjust the bending angles and forces to achieve the exact specifications required. Post – processing operations, such as deburring, polishing, and surface finishing, are also carried out to enhance the appearance and performance of the parts. Finally, each part is rigorously inspected to ensure it meets our strict quality standards before being delivered to the client.

Applications of Custom Stamped Parts in the Automotive Industry

In the automotive industry, our Custom Stamped Parts Services for sheet metal stamping and bending play a crucial role. We produce a wide range of components, from body panels and structural parts to interior trim pieces and brackets. The precision and strength of our stamped and bent parts are essential for ensuring the safety, durability, and performance of vehicles.

For example, automotive body panels require precise stamping to achieve the correct shape and fit, while structural components need to be bent and formed to provide the necessary strength and rigidity. Our custom – stamped parts are also used in engine compartments to create brackets and mounts that support various engine components, ensuring proper alignment and reducing vibrations. Additionally, in the interior of vehicles, our bent and stamped parts are used to create stylish and functional trim pieces, enhancing the overall aesthetic appeal and user experience.

Applications of Custom Stamped Parts in the Electronics and Architectural Sectors

In the electronics industry, our Custom Stamped Parts Services are highly valued for producing components such as enclosures, heat sinks, and connectors. Sheet metal stamping allows us to create precise and compact enclosures that protect sensitive electronic components from external elements while providing a sleek and professional appearance. Bending operations are used to shape heat sinks, optimizing their surface area for efficient heat dissipation.

In the architectural sector, our custom – stamped and bent parts are used to create a variety of products, including decorative elements, structural supports, and architectural cladding. The ability to customize the design and shape of these parts allows architects and designers to bring their creative visions to life. Whether it’s a unique facade for a commercial building or intricate metal railings for a residential project, our Custom Stamped Parts Services can deliver high – quality, tailor – made solutions that enhance the functionality and aesthetics of architectural structures.

Future Prospects of Custom Stamped Parts Services for Sheet Metal Stamping and Bending

Looking to the future, we are highly optimistic about the prospects of our Custom Stamped Parts Services for sheet metal stamping and bending. As industries continue to evolve and technology advances, the demand for customized, high – performance metal components will only increase. The growth of electric vehicles, the development of smart electronics, and the increasing focus on sustainable and innovative architectural designs will all drive the need for more advanced and specialized sheet metal stamped and bent parts.

We are committed to continuous research and development to stay at the forefront of this evolving market. Our team will explore new materials, innovative manufacturing techniques, and advanced design software to further enhance the capabilities of our custom – stamped parts services. By investing in state – of – the – art equipment and training our technicians to master the latest technologies, we aim to meet the evolving needs of our clients across various industries and remain a leading provider of customized sheet metal stamping and bending parts services.