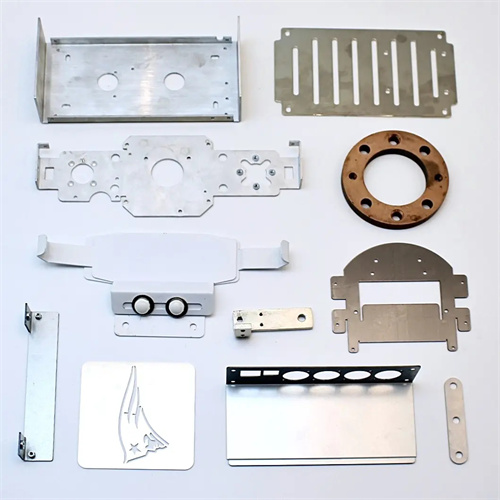

Introduction to Custom Stamped Parts of Stainless Steel Hardware Metal Blanks

As a team with a profound understanding of metal stamping and manufacturing, we recognize the significance of Custom Stamped Parts crafted from stainless steel hardware metal blanks. Stainless steel, renowned for its exceptional strength, corrosion resistance, and durability, serves as the ideal material for creating high – quality hardware components through the stamping process. These custom – stamped parts are essential in a wide array of industries, providing reliable and long – lasting solutions for various applications.

Metal blanks act as the starting point for our precision – engineered custom – stamped products. By leveraging advanced stamping techniques, we can transform these blanks into intricate and precisely – shaped stainless steel hardware components that meet the specific requirements of our clients. Whether it’s for architectural, automotive, or industrial applications, our Custom Stamped Parts of stainless steel hardware metal blanks are designed to offer superior performance and functionality, making them a trusted choice in the market.

The Remarkable Advantages of Custom Stamped Stainless Steel Hardware Metal Blanks Parts

We are well – acquainted with the remarkable advantages that our Custom Stamped Stainless Steel Hardware Metal Blanks Parts bring to the table. The foremost benefit lies in the inherent properties of stainless steel. Its outstanding corrosion resistance makes these parts suitable for use in diverse environments, from coastal areas exposed to saltwater to industrial settings with harsh chemicals. This resistance ensures that the custom – stamped hardware maintains its integrity and appearance over extended periods, reducing the need for frequent replacements.

In addition to corrosion resistance, the high strength and durability of stainless steel contribute to the reliability of our custom – stamped parts. They can withstand heavy loads, mechanical stresses, and repeated use without deforming or breaking. This makes them ideal for applications where robust and long – lasting hardware is required. Moreover, the precision of our stamping process allows for the creation of complex geometries and tight tolerances, ensuring a perfect fit within various systems. The combination of these advantages makes our Custom Stamped Stainless Steel Hardware Metal Blanks Parts a top – tier solution for numerous industries.

The Elaborate Manufacturing Process of Custom Stamped Parts

Our manufacturing process for Custom Stamped Parts of stainless steel hardware metal blanks is a meticulously planned and executed sequence of steps. It commences with in – depth consultations with our clients to fully understand their specific needs, including the intended application, design specifications, and performance requirements. Our team of experienced engineers then utilizes advanced CAD/CAM software to create detailed 3D models of the parts, optimizing the design for both functionality and manufacturability.

Once the designs are finalized, we source high – quality stainless steel metal blanks from trusted suppliers. These blanks are then fed into our state – of – the – art stamping presses, which are equipped with custom – made dies. During the stamping process, we closely monitor and control parameters such as pressure, speed, and temperature to ensure consistent quality and dimensional accuracy. After stamping, the parts undergo a series of post – processing operations, including deburring to remove sharp edges, heat treatment to enhance mechanical properties, and surface finishing to improve appearance and corrosion resistance. Rigorous quality inspections are carried out at every stage to guarantee that each Custom Stamped Part meets our exacting standards before being delivered to the client.

Applications of Custom Stamped Parts in the Architectural Industry

In the architectural industry, our Custom Stamped Parts of stainless steel hardware metal blanks play a crucial role in enhancing both the functionality and aesthetics of buildings. They are used in a variety of applications, such as door handles, hinges, and decorative fixtures. The corrosion resistance of stainless steel ensures that these hardware components maintain their sleek appearance even in outdoor environments, where they are exposed to rain, sunlight, and pollutants.

For interior applications, the strength and durability of our custom – stamped parts provide reliable support for heavy doors and partitions. The precision of the stamping process allows for the creation of unique and intricate designs, adding a touch of elegance to architectural projects. Whether it’s for commercial buildings, residential complexes, or public structures, our Custom Stamped Parts of stainless steel hardware metal blanks contribute to the overall quality and longevity of architectural installations.

Applications of Custom Stamped Parts in the Automotive and Industrial Sectors

In the automotive sector, our Custom Stamped Parts of stainless steel hardware metal blanks are widely utilized in various components. From engine parts that need to withstand high temperatures and mechanical stresses to exterior trim pieces that require corrosion resistance and aesthetic appeal, our custom – stamped products meet the diverse requirements of the automotive industry. The high strength of stainless steel ensures the reliability of these parts, contributing to the overall performance and safety of vehicles.

In the industrial sector, our custom – stamped parts are essential for manufacturing machinery, equipment, and tools. They are used in components such as brackets, connectors, and fasteners, where durability and resistance to wear and tear are critical. The ability of stainless steel to maintain its properties in harsh industrial environments makes our Custom Stamped Parts a reliable choice for ensuring the smooth operation of industrial processes and the longevity of equipment.

Future Prospects of Custom Stamped Stainless Steel Hardware Metal Blanks Parts

Looking to the future, we are highly optimistic about the prospects of our Custom Stamped Stainless Steel Hardware Metal Blanks Parts. As industries continue to evolve and technology advances, the demand for high – quality, durable, and customizable hardware components will only increase. The growth of sustainable building practices in the architectural industry, the development of electric vehicles in the automotive sector, and the expansion of advanced manufacturing technologies in the industrial field will all drive the need for more innovative and reliable stainless steel stamped parts.

We are committed to continuous research and development to stay at the forefront of this evolving market. Our team will explore new stainless steel alloys, innovative stamping techniques, and advanced design methodologies to further enhance the performance of our Custom Stamped Parts. By investing in cutting – edge equipment and maintaining a focus on quality, we aim to meet the evolving needs of our clients across various industries and remain a leading provider of custom – stamped stainless steel hardware metal blanks parts.